64

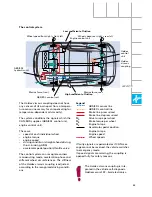

The vehicle electrical system

The electrical/electronic connector stations as

well as the necessary control units are decen-

tralised to meet the requirements.

This ensures an optimum wiring configura-

tion.

Electrics

Airbag control unit J234

Radiator fan control

unit J293

Fuse box, battery

ABS-EDL control

unit J104

Engine control unit J220

Combi processor in the

dash panel insert J218

Immobiliser control

unit J362

Navigation operating elec-

tronics control unit J402

Connector point, A-pillar

Socket (power windows,

radio, CLS-ATA light, mirror

adjustment)

Lateral acceleration sen-

sor, passenger’s side