UNDER NO CIRCUMSTANCES SHOULD THE HEAD-SHELL WIRES BE

SOLDERED DIRECTLY TO THE CONNECTION PINS OF THE CARTRIDGE

BODY. HEAT APPLIED TO THE CONNECTION PINS WILL CAUSE

IRREPARABLE DAMAGE

.

The cartridge body is equipped with threaded holes, to make the mounting procedure

easier and more secure. They are spaced 12.7mm apart, (across the width of the

cartridge body) which is the industry standard distance. Additionally, the IO Limited

has six threaded mounting holes – three per side – rather than the conventional two;

this is to provide the most rigid and secure coupling possible between cartridge and

headshell.

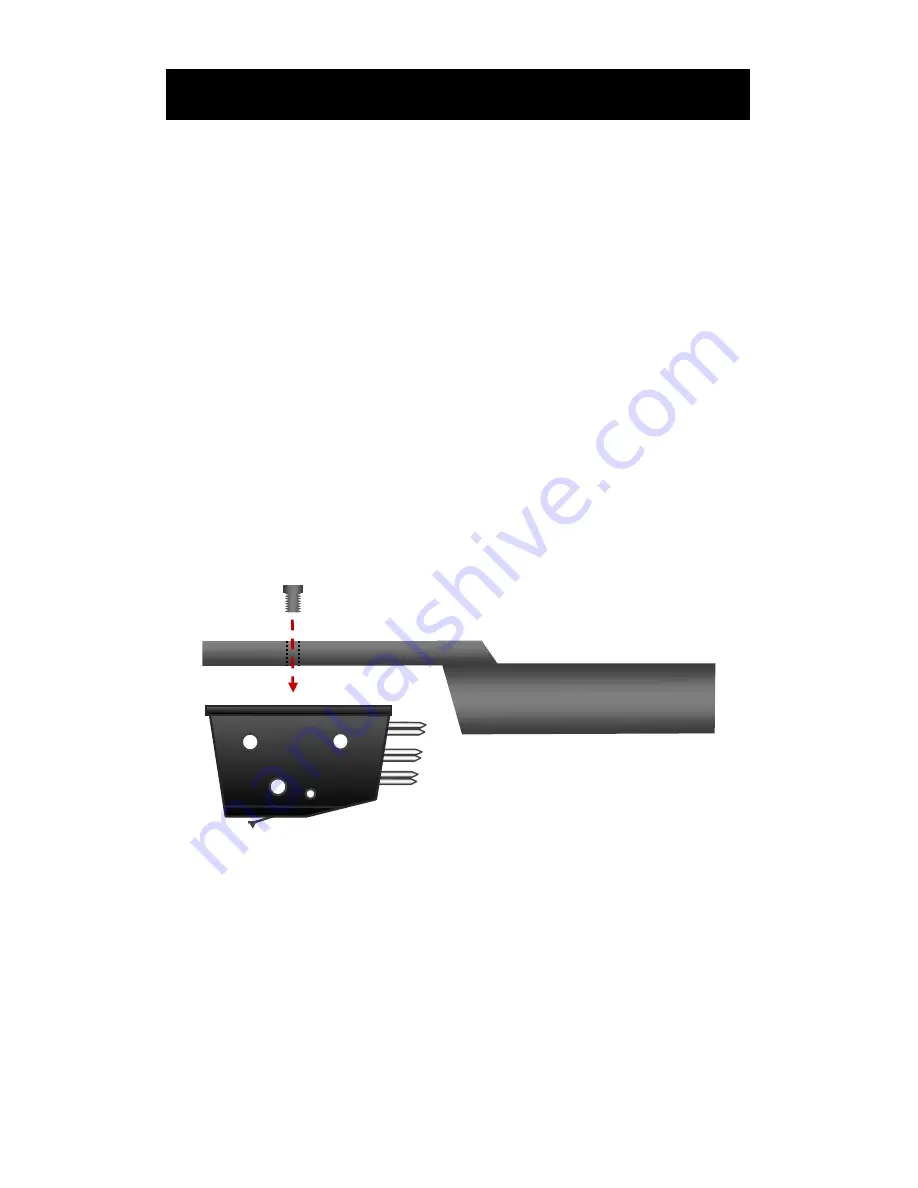

A pair of high quality hex head bolts and an appropriately sized wrench are provided

for mounting the cartridge body to the head-shell.

Pass the bolts down (from above) through the mounting holes in the head-shell, and

align them with the threaded holes in the top surface of the cartridge body.

Gently tighten the bolts to hold the cartridge securely in place. Do not fully tighten the

bolts until all cartridge alignment procedures have been completed. (Once all

alignment has been finalized, the extra four fixing bolts may be installed if you wish,

to maximize the rigidity of the cartridge / headshell interface. Please remember to

readjust the tracking weight!).

Once the cartridge is in place, set the correct tracking weight. Do this BEFORE the

final adjustments are made for cartridge alignment, as this will help to ensure the

cantilever is not damaged due to excessive tracking force. Once final alignment

adjustments have been made, it will be necessary to check the tracking weight again,

as any movement of the cartridge body will change the tracking weight.

The optimum tracking weight for the IO Limited is

2.5g.

Remember to remove the

clear acrylic stylus guard before setting the tracking weight!

IO LIMITED INSTALLATION continued…