Section 03

ENGINE

Subsection 11

(GEARBOX)

VMR2004_134_03_11A.FM

03-11-19

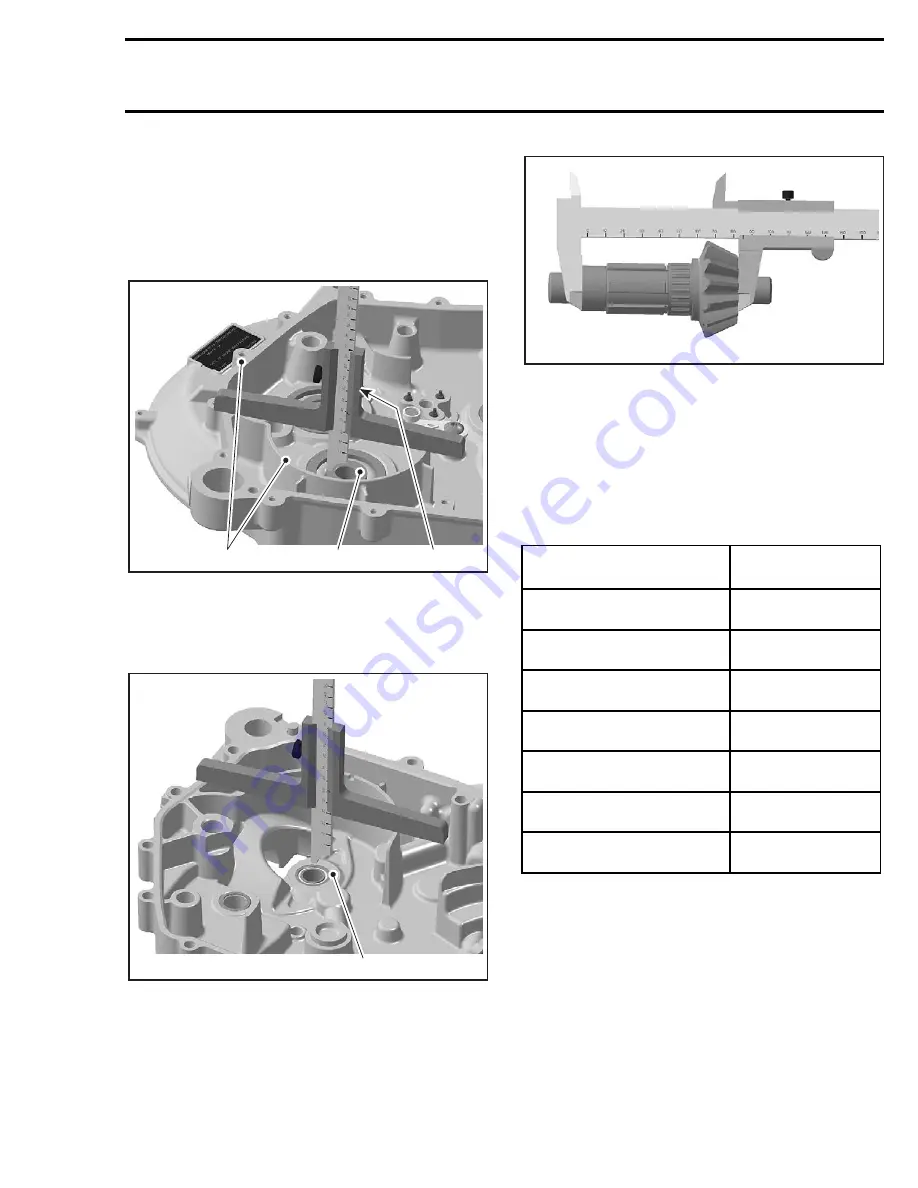

Measure shim on PTO side:

NOTE:

Clean mating surfaces of crankcase before

measurement. Refer to crankcase assembly pro-

cedure.

•

F

= Distance between mating surface (crank-

case PTO) to ball bearing inner race.

1. Ball bearing inner race

2. Mating surface of crankcase PTO

3. Depth gauge

•

G

= Distance between mating surface of crank-

case MAG and butting face.

1. Butting surface

•

H

= Distance between butting faces of bevel gear

shaft.

•

I

= Theoretical shim thickness.

•

J

= Shim selected in accordance with

I

.

Use following course of calculation to get the the-

oretical thickness I for washer

no. 27

.

I = F + G - H - A - E

NOTE:

Take theoretical value

I

and choose shim

J

(PTO side shim) from the below table

.

NOTE:

For example, if the measured thickness is

1.53 mm (.0602 in), choose the shim 150.

NOTE:

Bevel gear axial clearance of 0.02 to 0.11 mm

(.00079 to .00433 in) is included in the above table.

2

R400trans26A

1

3

1

R400trans28A

CALCULATED THICKNESS

(I)

SHIM NUMBER

(J)

1.22 mm to 1.31 mm

(.0480 to .0516 in)

120

1.32 mm to 1.41 mm

(.0519 to .0555 in)

130

1.42 mm to 1.51 mm

(.0559 to .0594 in)

140

1.52 mm to 1.61 mm

(.0598 to .0634 in)

150

1.62 mm to 1.71 mm

(.0638 to .0673 in)

160

1.72 mm to 1.81 mm

(0.0677 to .0713 in)

170

1.82 mm to 1.91 mm

(.0717 to .0752 in)

180

R400trans29A