Section 03

ENGINE

Subsection 08

(LUBRICATION SYSTEM)

VMR2004_131_03_08A.FM

03-08-9

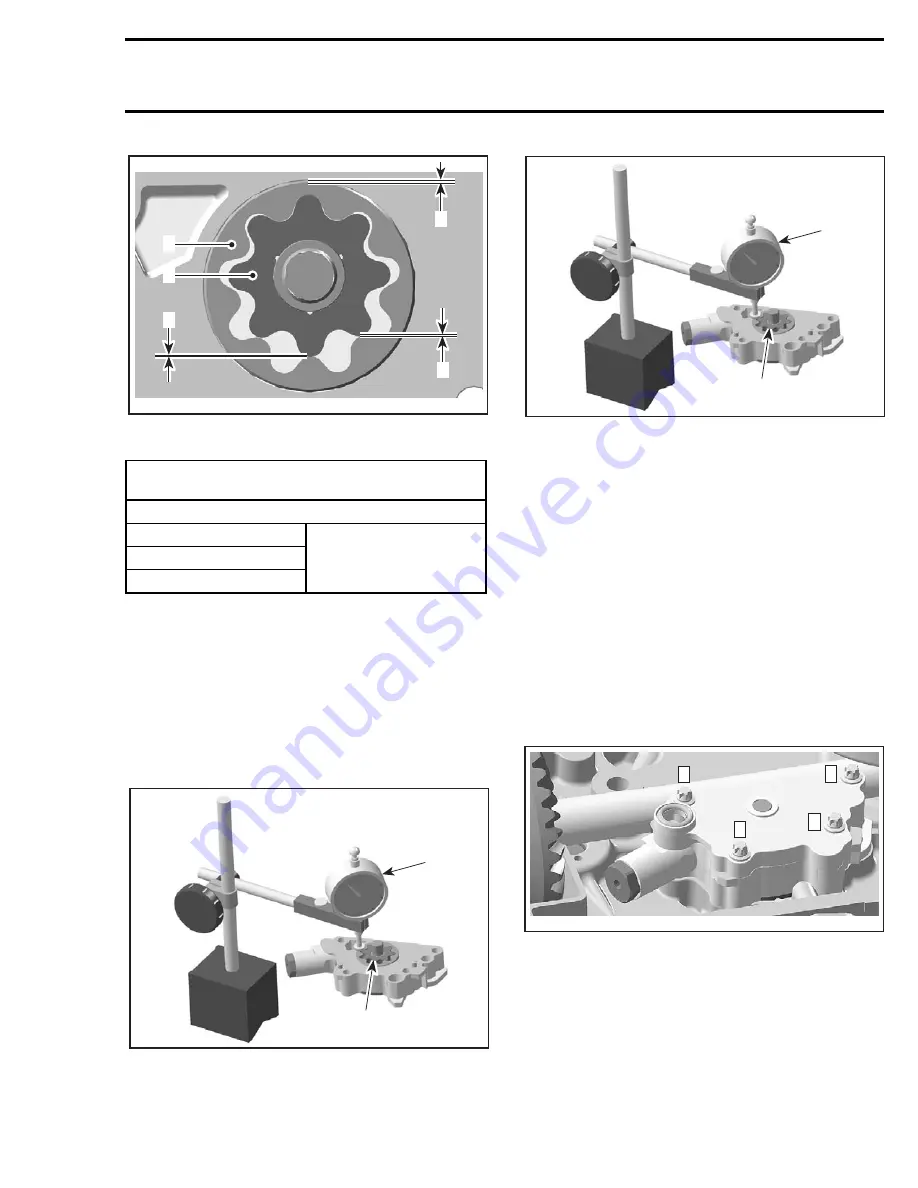

1. Outer rotor

2. Inner rotor

If clearance between inner and outer rotor ex-

ceeds the tolerance, replace oil pump shaft as-

sembly. Ensure to also check oil pump housing

and cover. If damaged, replace the complete oil

pump assembly.

If clearance between outer rotor and its bore in oil

pump exceeds the tolerance, replace the complete

oil pump assembly.

Using a dial indicator, measure side wear as shown.

1. Oil pump housing surface

2. Dial indicator

1. Oil pump outer rotor surface

2. Dial indicator

Difference between pump housing and outer rotor

should not exceed 0.1 mm (.004 in). If so, replace

replace the complete oil pump assembly.

NOTE:

When the axial clearance of the oil pump

shaft assembly increases, the oil pressure de-

creases.

Check the inside of oil pump housing and its cover

for scoring or other damages. If so, change the

complete oil pump assembly.

Installation

For installation, reverse the removal procedure.

Tightening oil pump housing screws as per follow-

ing sequence.

Install the O-ring

no. 27

on oil pump cover.

CAUTION:

Never apply any sealing compound

on split surfaces of oil pump.

Final Test

After engine is completely reassembled, start en-

gine and make sure oil pressure is within specifi-

cations.

OUTER AND INNER ROTOR CLEARANCE

mm (in)

SERVICE LIMIT

A

0.25 mm (.009 in)

B

C

B

R400motr127A

A

C

1

2

1

2

R400motr128B

1

2

R400motr128B

1

R400motr119B

3

2

4