Section 03

ENGINE

Subsection 09

(CYLINDER AND HEAD)

03-09-18

VMR2004_132_03_09A.FM

Installation

For installation, reverse the removal procedure.

Pay attention to the following details.

CAUTION:

Make sure the thrust washer

no. 39

is installed before installing valve stem seal

no. 38

.

Apply engine oil on valve stem and install it.

CAUTION:

Be careful when valve stem is passed

through sealing lips of valve stem seal.

1. Thrust washer

2. Sealing lips of valve stem seal

To ease installation of cotters, apply oil or grease

on them so that they remain in place while releas-

ing the spring.

After spring is installed, ensure it is properly

locked by tapping on valve stem end with a soft

hammer so that valve opens and closes a few

times.

CAUTION:

An improperly locked valve spring

will cause engine damage.

VALVE GUIDE PROCEDURE

Removal

Remove:

– cylinder head (see CYLINDER HEAD

above)

– valve spring (see VALVE SPRING

above)

– valves (see VALVE

above).

NOTE:

Clean valve guide area from contamination

before removal.

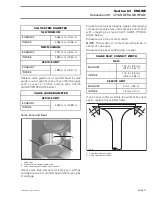

Using valve guide remover (P/N 529 035 924),

remove valve guide

no. 40

with a hammer.

1. Valve guide remover

2. Valve guide

Inspection

Always replace valve stem seals whenever cylin-

der head is removed.

Clean the valve guide bore before reinstalling the

valve guide into cylinder head.

Installation

For installation, reverse the removal procedure.

Pay attention to the following details.

Use valve guide installer (P/N 529 035 853) to in-

stall valve guide

no. 40

.

1. Valve guide installer

2. Valve guide

NOTE:

Apply anti-seize lubricant (P/N 293 800

070) on valve guide prior to install it into the cylin-

der head.

1

R400motr85A

2

2

R400motr86A

1

1

R400motr87A

2