Section 03

ENGINE

Subsection 10

(CRANKSHAFT/BALANCER SHAFT)

VMR2004_133_03_10A.FM

03-10-3

GENERAL

During assembly/installation, use the torque values

and service products as in the exploded views.

Clean threads before applying a threadlocker. Re-

fer to SELF-LOCKING FASTENERS and LOCTITE

APPLICATION at the beginning of this manual for

complete procedure.

CRANKSHAFT LOCKING

PROCEDURE

Removal

Unplug spark plug cable then remove the spark plug.

Remove valve cover (refer to CYLINDER AND HEAD).

To place piston at TDC, pull rewind starter to rotate

crankshaft until piston is at TDC compression po-

sition.

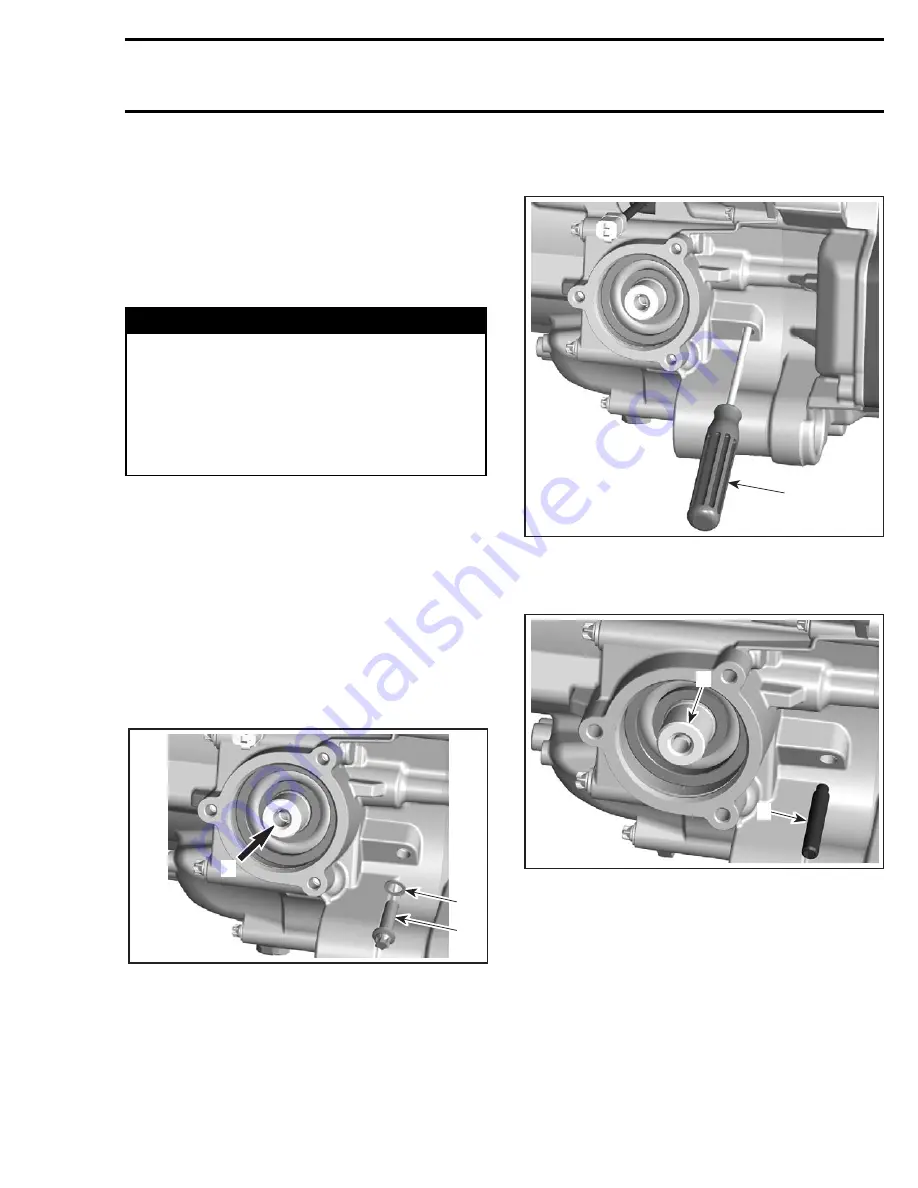

Remove screw

no. 1

and sealing washer

no. 2

.

1. Screw

2. Sealing washer

3. Output shaft on front side of vehicle

Use a screwdriver to check if groove in crankshaft

is aligned with the hole.

1. Screwdriver

Lock crankshaft with crankshaft locking bolt (P/N

529 035 617).

1. Crankshaft locking bolt

2. Front output shaft area

Install camshaft locking tool (P/N 529 035 926).

NOTE:

At piston TDC, the printed marks on the

camshaft timing gear have to be parallel to cylinder

head base as per following illustration.

WARNING

Torque wrench tightening specifications must

strictly be adhered to.

Locking devices (ex.: locking tabs, elastic

stop nuts, self-locking fasteners, etc.) must

be installed or replaced with new ones where

specified. If the efficiency of a locking device

is impaired, it must be renewed.

R400motr234A

1

2

3

1

R400motr235A

R400motr236A

1

2