Section 03

ENGINE

Subsection 10

(CRANKSHAFT/BALANCER SHAFT)

03-10-10

VMR2004_133_03_10A.FM

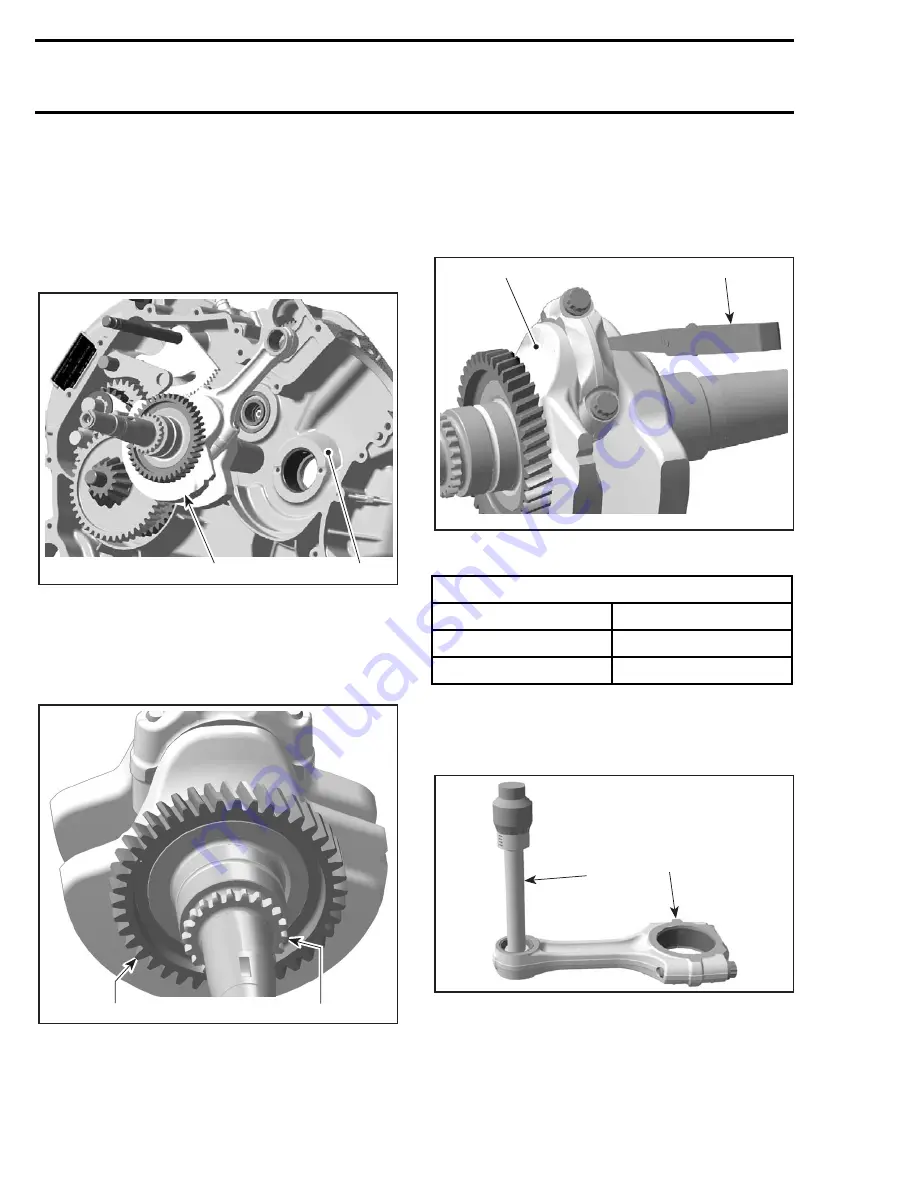

CRANKSHAFT

Removal

Remove:

– balancer shaft (see BALANCER SHAFT above)

– crankshaft

no. 3

.

1. Crankshaft

2. Crankcase PTO

Inspection

Replace crankshaft if the gears are worn or other-

wise damaged.

1. Balancer gear

2. Crankshaft timing gear

Connecting Rod Big End Axial Play

Using a feeler gauge, measure distance between

butting face of connecting rod and crankshaft coun-

terweight. If the distance exceeds specified toler-

ance, replace the crankshaft.

1. Crankshaft

2. Feeler gauge

Connecting Rod/Piston Pin Clearance

Measure piston pin. Compare to inside diameter of

connecting rod

no. 6

.

1. Bore gauge

2. Connecting rod

1

R400motr26A

2

2

R400motr27A

1

CONNECTING ROD BIG END

MINIMUM (new)

0.100 mm (.004 in)

MAXIMUM (new)

0.352 mm (.014 in)

SERVICE LIMIT

0.5 mm (.02 in)

1

R400motr28A

2

1

R400motr29A

2