www.ausrv.com

Ph: 833 872 8778

83

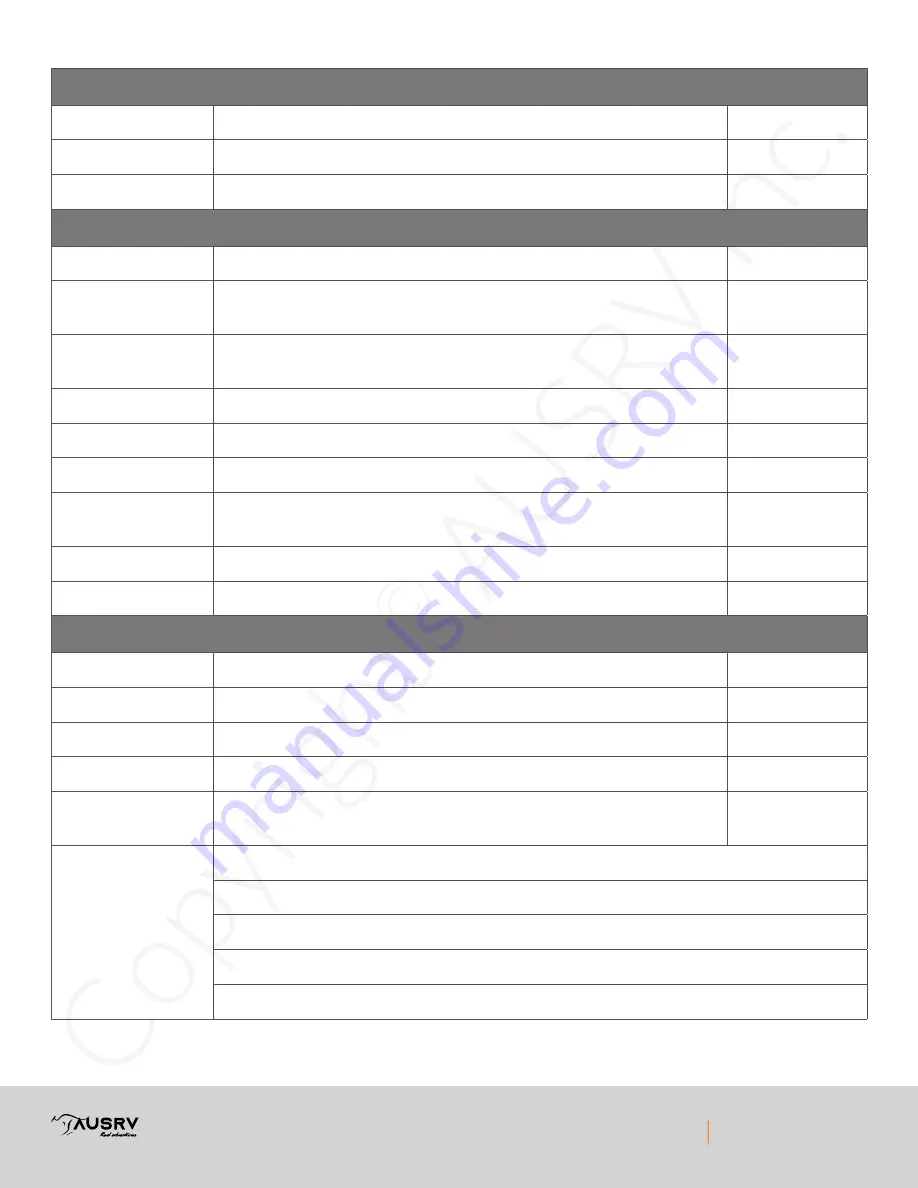

110 volt Electrical

RCD Unit

Check operation of RCD via test button

Shore power input

Inspect shore power input plug and cover are free of damage

Earthing

Carry out resistance check

Caravan Body

Hatches & Doors

Check and lubricate locks

Seals

Check condition and correct latch/ lock adjustment for correct 30-50%

compression.

Body

Inspect joint sealants inside and out.

Inspect for soft spots on floor (Timber Floor Models).

General fixings

Check all structural fixings are secure.

Ventilation

Inspect for obstruction and vents operating correctly.

Fire Extinguisher

Inspect extinguisher is charged and within service date.

Smoke Alarm

Test and inspect.

Replace battery.

Window Blinds

Inspect and adjust tension where necessary

Damp Check

Inspect trailer for any dampness.

Plumbing

Hot Water System

De-scale hot water service (if installed)

Water Tanks

Treat tanks and entire system with bacteria killing tank cleaner and flush.

Grey Water Tank

Treat with tank cleaner and flush.

Drain Fitting

Check all metal drain fittings for corrosion

Water System

Inspect for leaks. Turn on pump and ensure it doesn’t start due to loss of

pressure.

Service Center

Notes

Summary of Contents for AUSRV LX 2021

Page 71: ...www ausrv com Ph 833 872 8778 71 Schematics Electrical Diagram ...

Page 75: ...www ausrv com Ph 833 872 8778 75 Hub Assembly ...

Page 76: ...www ausrv com Ph 833 872 8778 76 Trailing Arms and Bushes ...

Page 100: ...www ausrv com Ph 833 872 8778 100 Trip Name Date Miles Start Miles Finish Cumulative Miles ...