Aussie BB Hire Series … Operation & Maintenance Manual

11

Aussie Pumps

June 2016

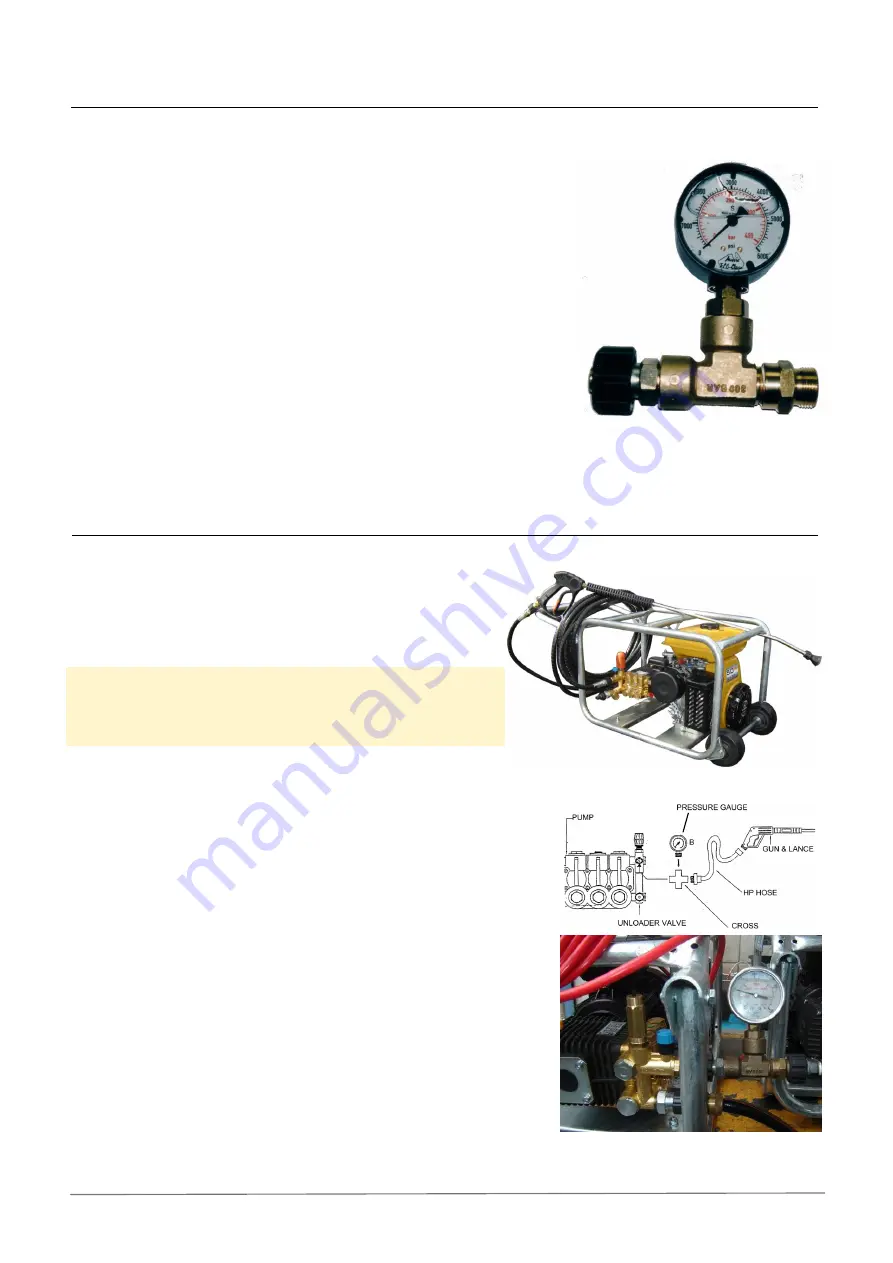

PRESSURE TESTING INSTRUCTIONS …. 2,000 PSI PETROL ENGINE BLASTERS

1.

Connect machine to mains pressure water supply,

ensuring that water is passing freely through the

pump at the correct flow rate for specified pump by

holding the gun trigger open.

2.

Ensure that nozzle fitted in lance is the correct size

(BB100 nozzle should be 035).

Replace nozzle if

worn or damaged.

Check there are no leaks in the

hose or high pressure connections.

3.

Check oil level in pump, gearbox and engine before further

testing.

4.

Fit pressure gauge kit between high pressure outlet of pump

and high pressure hose.

5.

Turn on engine with the trigger on the gun pressed. Check

the engine rpm is set to 3200. Adjust if necessary. Let the

engine run for a few minutes to warm up.

6.

Check the pressure on the gauge (BB100 should read 2,000

psi) when blaster is operating. If adjustment is required refer

to next instructions .

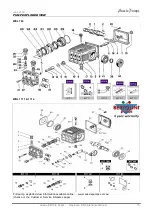

AUSSIE PRESSURE CLEANER TEST SET

Everybody knows that professional pressure cleaners

occasionally need to have their pressure tested and sometimes

reset. Doing this efficiently, and in line with our professional

recommendations is not easy unless you have the right

equipment.

Checking pressure regularly will tell you if nozzles are worn, if the

pressure regulator is worn, if there are leaks in the system, if the

valves are sticking and signal other problems that can manifest

themselves in low pressure operation.

The Aussie Test Set (Part number ATESTSET) will solve those

problems. Consisting of a convenient brass T with M22 quick

coupler and 6,000 psi pressure gauge you can check to make

sure everything is operating as it should. Detailed instructions are

included with each kit.

AUSSIE BLASTER PRESSURE TESTING & SETTING

Pressure gauge kit fitted between pump high

pressure outlet and high pressure hose