9

NOTE:

notches closest

together to outside

Rear Leg Assembly

Cylinder Support

Side Crossbrace

Right

Bowl Support

Left

Bowl

Support

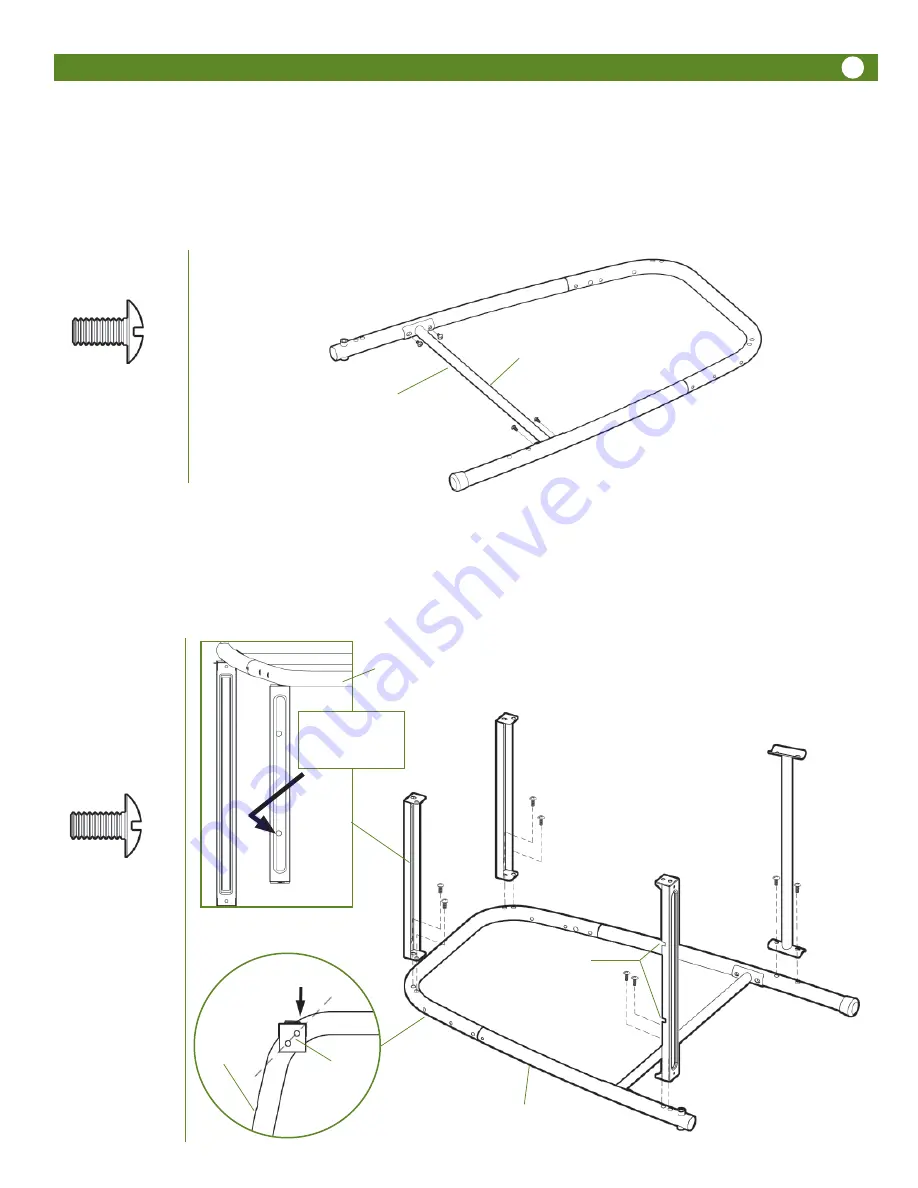

Step 3

Rear Crossbrace Assembly

Attach Rear Crossbrace inside Rear Leg Frame with 4) 1/4-20 x .39” Bolts. Note: The flanges on the ends of the cross-

brace tube are angled inward toward the top to match the angle of the legs.

1/4-20 x .39” Bolt

4 pcs

Step 4

Bowl Supports, Cylinder Support and Side Crossbrace Assembly

Attach the Left and Right Bowl Supports, Clyinder Support and Crossbrace to rear leg assembly with 8) 1/4-20 x .39”

Bolts. Note: Each part must be oriented as shown for proper assembly. Bolts should be snug but do NOT tighten com-

pletely at this stage. Note: The flanges on the ends of the crossbrace tube are angled inward toward the top to match

the angle of the legs.

1/4-20 x .39” Bolt

8 pcs

Rear Leg

Assembly

Holes in Bowl

Support align

with leg

Low side of raised area

to center

Rear Leg Assembly

Left Bowl Support

Holes are closest to

OUTSIDE edge

Rear

Crossbrace

NOTE:

Threaded Insert on top