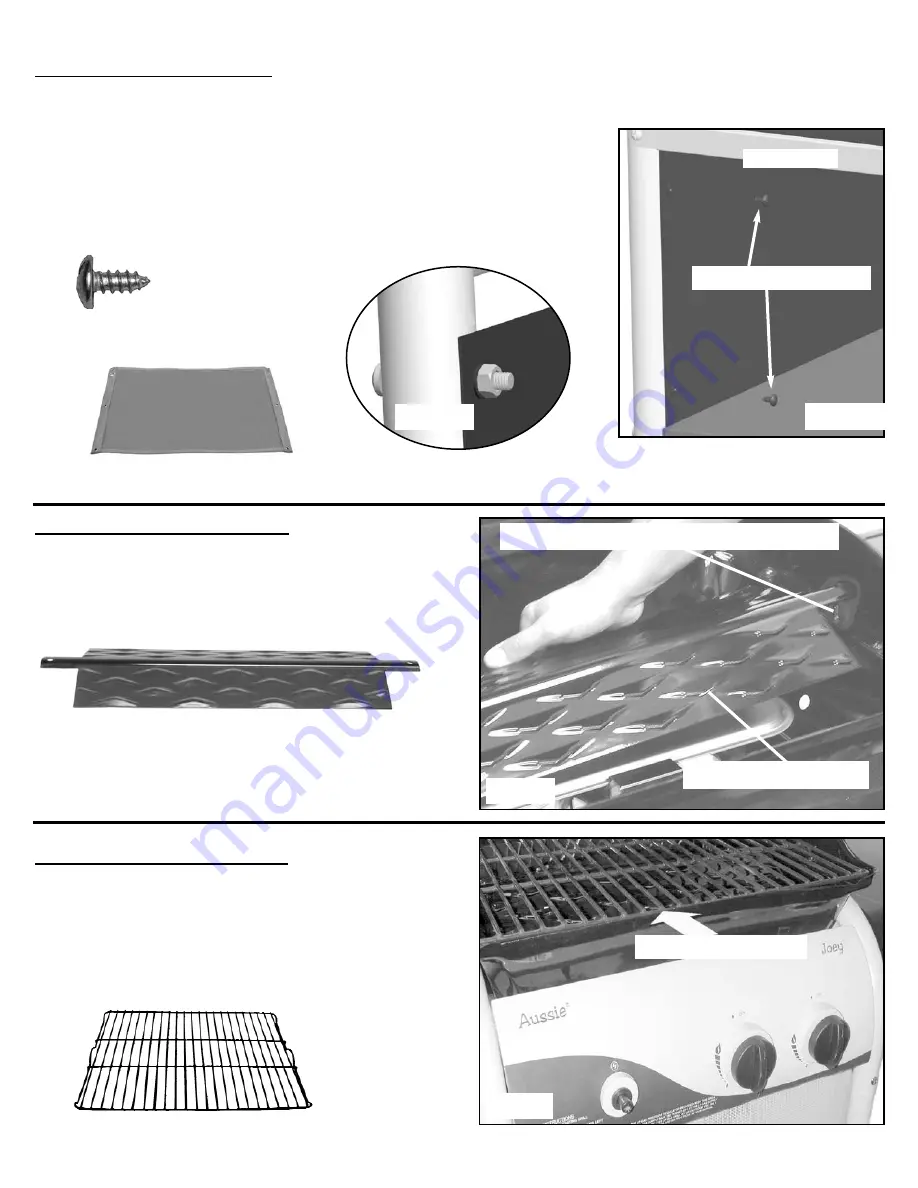

Step 10) Install Cooking Grid:

(Note Warming Rack already installed.)

Lay Cooking Grid onto the Bowl ridges over the

Flame Diffuser and Main Burner. (FIG. 10)

10

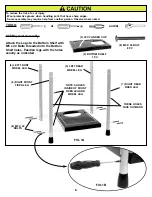

Step 8) Attach Front Panel:

Remove the M6 nut used to attach the upper and lower leg

sections. Place the large eyelet over the bolt and replace

the nut. (FIG. 8B) Using the ST4.0 Screw, secure the Fabric

Panel to holes in the lower legs over the eyelets. (FIG. 8A)

(34) COOKING GRID

1 PC

FIG. 8A

FIG. 10

(34) COOKING GRID

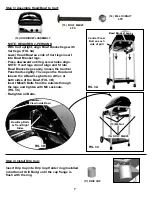

Step 9) Install Flame Diffuser:

Place the Flame Diffuser over the Main Bowl

Burner, onto the two mounting studs on each

side of the Bowl. (FIG. 9)

(35) FLAME DIFFUSER

Flame Diffuser mounting stud in Bowl.

(35) Flame Diffuser

FIG. 9

(37) FABRIC PANEL

(21) SCREW, ST4.0 x 10

(21) SCREW, ST4.0 x 10

4 PC

FIG. 8B

RIGHT SIDE