15

PARAMETER CHECKING AND ADUSTMENT

Parameter list

Some parameters can be checked and adjusted by the controller. Below is the parameter list.

No.

Name

Instruction

1

Compressor running Frequency

Current hz

2

EEV Open degree

Current Value/5

3

Ambient Temperature

Current

℃

4

Outlet Water Temp.

Current

℃

5

Exhaust gas Temp.

Current

℃

6

Return gas Temp.

Current

℃

7

Coil Temp.

Current

℃

8

4-way Valve outlet Temp.

Current

℃

9

Water Circulaton Pump

0-off

;

1-on

10

4-way Valve Status

0-off

;

1-on

11

Standby

/

12

Standby

/

13

Standby

/

14

Standby

/

15

Standby

/

16

Running Current of Compressor

Current*10

17

Voltage

Current/10

18

Standby

/

19

Standby

/

20

Standby

/

21

Fan speed

Current/10

Malfunctioning of the unit and maintenance

When an error occurs or the protection mode is set automatically, the circuit board and the wired

controller will both display the error message.

Error

Meaning

Analysis

Diagnosis

Solution

P01

Water Flow failure

1.

No water flow;

2.

Flow switch failure;

3.

Water system block.

1.Check if water in valve is closed or no

water in;

2.Check if flow switch is blocked or

damaged;

3.Check if“Y”Shape filter blocked.

1.

Open the valve;

2.

Change a new flow switch;

3.Clean or change a new filter.

P02

High

pressure

protection

1.Water flow is too small

2.High-pressure switch is

damaged;

3.Refrigerant system block

;

4.EEV deadlock.

1.Check if water flow is not enough or

water pump flow is not enough;

2.Check if high-pressure switch is off;

3.Check if refrigerant system is blocked;

4.When heat pump is off and turn the

heat pump on and off to check if EEV

can be listenned by sound of reset.

1.Reinject water or change to a

new pump of larger water flow;

Change a new high-pressure switch;

3.Change a new filter;

4.Change a new EEV

Summary of Contents for Eco Full Inverter EFI 14

Page 2: ...0 ...

Page 4: ...1 ...

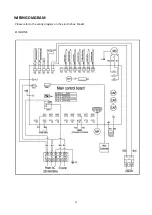

Page 25: ...21 WIRING DIAGRAM Please refer to the wiring diagram on the electricbox Model EFI14 17 23 ...

Page 28: ...24 ...

Page 29: ...25 User Manual for APP Application EFI Full Inverter Series ...