10

Raptor Electric Operator’s Manual

July 2012

Australian Pump Industries

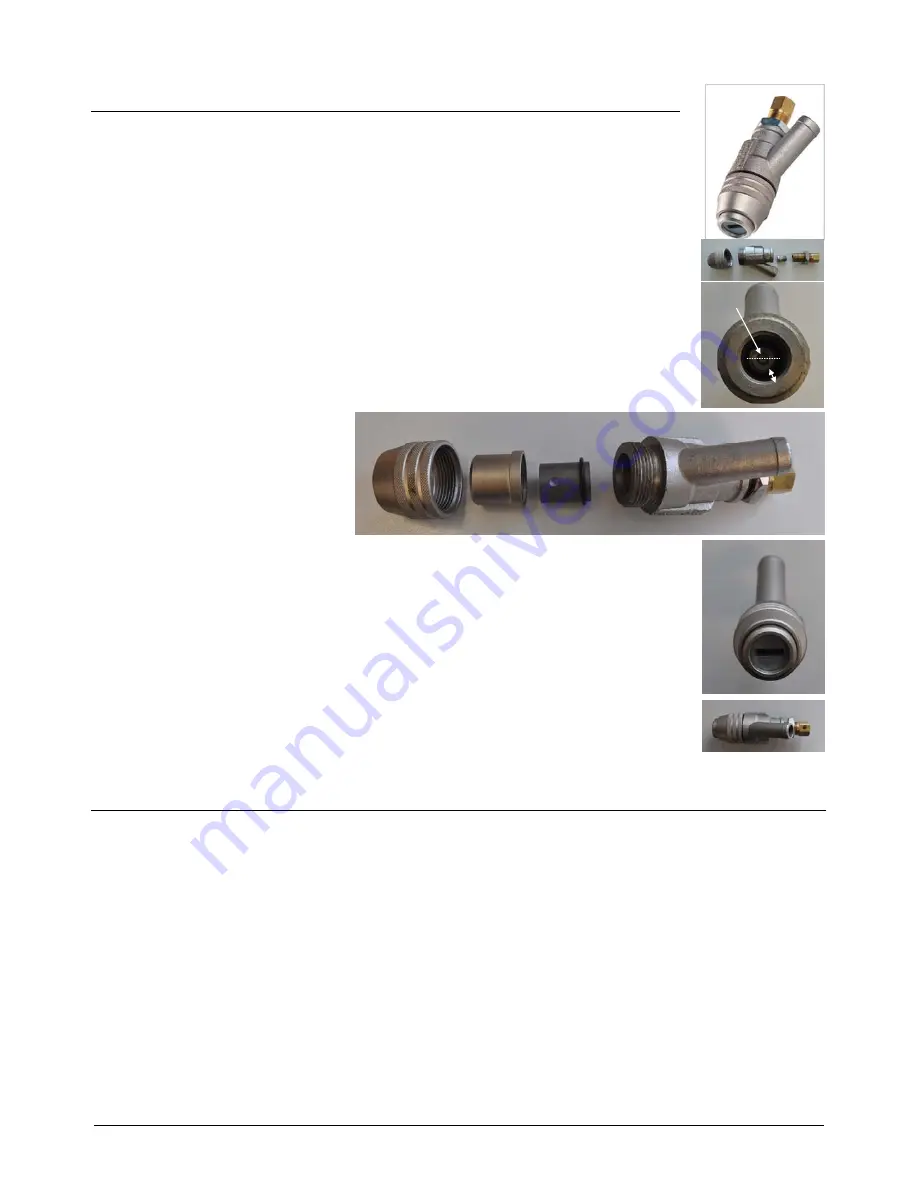

AUSSIE GRIT BLAST HEAD SET UP INSTRUCTIONS

(optional accessory)

Note: the Aussie Grit Blast head does not come with a nozzle. You will need a 15º

Aussie Laser Cut ’M’ series nozzle that suits the high pressure blaster the kit

will be used with.

1.

Unwind the tail coupling and remove top of the blast head. Screw in the

nozzle to the tail.

2.

Replace the tail and ensure that the tip of the nozzle is a minimum of 28mm

from leading edge of body and a maximum of 36mm. The fan spray from the

nozzle should be perpendicular to the sand intake tail. Mark the top side of

the hexagonal coupling for reference.

3.

Line up the dimple in the ceramic nozzle perfectly with the sand intake tail

and hold in place with the holder. Screw down the head locking nut.

4.

The fan produced by the two

nozzles must be aligned.

5.

Connect grit blast head to hp

gun/lance and activate the gun

with the high pressure blaster

running. Check the fan jet leaving the nozzle is the full width of the slot.

Adjust by rotating hexagonal tail coupling, ensuring that the marked side of

the tail always finishes on top.

6.

With the high pressure washer turned off, connect the sand hose to the sand

intake tail and secure with hose clips. Secure sand blast probe to other end

of the hose in the same way. The probe should be lodged into the sand bag.

WARNING: To reduce the risk of injury, always protect eyes and face with

goggles and mask, and hands and arms with heavy work gloves when

spraying abrasive materials.

GRIT BLAST INSTRUCTIONS

1.

Connect and open the water supply line before starting the pressure washer.

2.

Squeeze the gun trigger to bleed air as normal.

3.

Turn on the pressure washer and squeeze the gun trigger to activate the spray.

CAUTION:

Always test spray on a scrap of similar material first! The high pressure spray could

damage the surface if the grit blaster is held too close.

4.

To determine best distance for grit blasting, start with the spray nozzle a metre away from the

surface and gradually move closer, frequently checking the surface for damage.

6.

Always point the nozzle downward when not spraying. This prevents water from entering the sand

supply. If water does get into the sand supply hose, remove the probe from the sand, hold the gun

trigger open, and let the hose air dry. Always be sure the sand hose is dry before using.

7.

Keep the sand covered to prevent the overspray from wetting the sand. Do not allow small pieces

of the sand bag to fall into the sand supply. A smaller piece could prevent the flow of sand.

Min 28mm

Max 36mm

Check angle of jet from

nozzle

Head locking nut holder ceramic piston with dimple

Sand intake tail

7,300 psi grit blast

head (C4700.18)