15

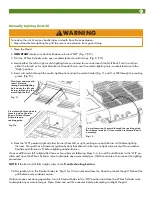

LP Hose and Regulator

To reduce the risk of serious bodily injury or death

from fire or explosion:

• Clean and inspect the gas hose/regulator before

each use of the outdoor cooking gas appliance.

The gas hose/regulator must be replaced prior to

being used, if there is evidence of excessive abra-

sion or wear, or if the hose is cut or leaks.

• Use only the gas hose/regulator assembly that

has been supplied with this gas grill. Do not

use hose/regulator from another manufacturer.

Replacement gas hose/regulator assembly must be

specified by this grill’s manufactuer before using.

• Always check for gas leaks when you connect

and disconnect the hose/regulator to the LP Gas

Cylinder, especially after a period of storage (for

example, over winter).

• Make sure there are no sharp bends in the hose.

• Make sure the hose/regulator does not contact any

heated surfaces.

WARNING

!

NOTE:

If the hose/regulator assembly is not working properly

and you need a replacement, contact

Customer Service

at 1-800-251-7558

or go to

www.aussiegrills.com

.

Be sure to

have the grill model number and serial

number

printed on the black label, located inside the

left door of the cabinet.

If you need a replacement

part under warranty, a proof of purchase will be

necessary

. You will be asked to forward your proof of

purchase via e-mail or to fax your proof of purchase

to 423-639-1055 and reference your model and serial

number.

It is important to register your grill and

retain your receipt.

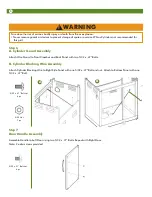

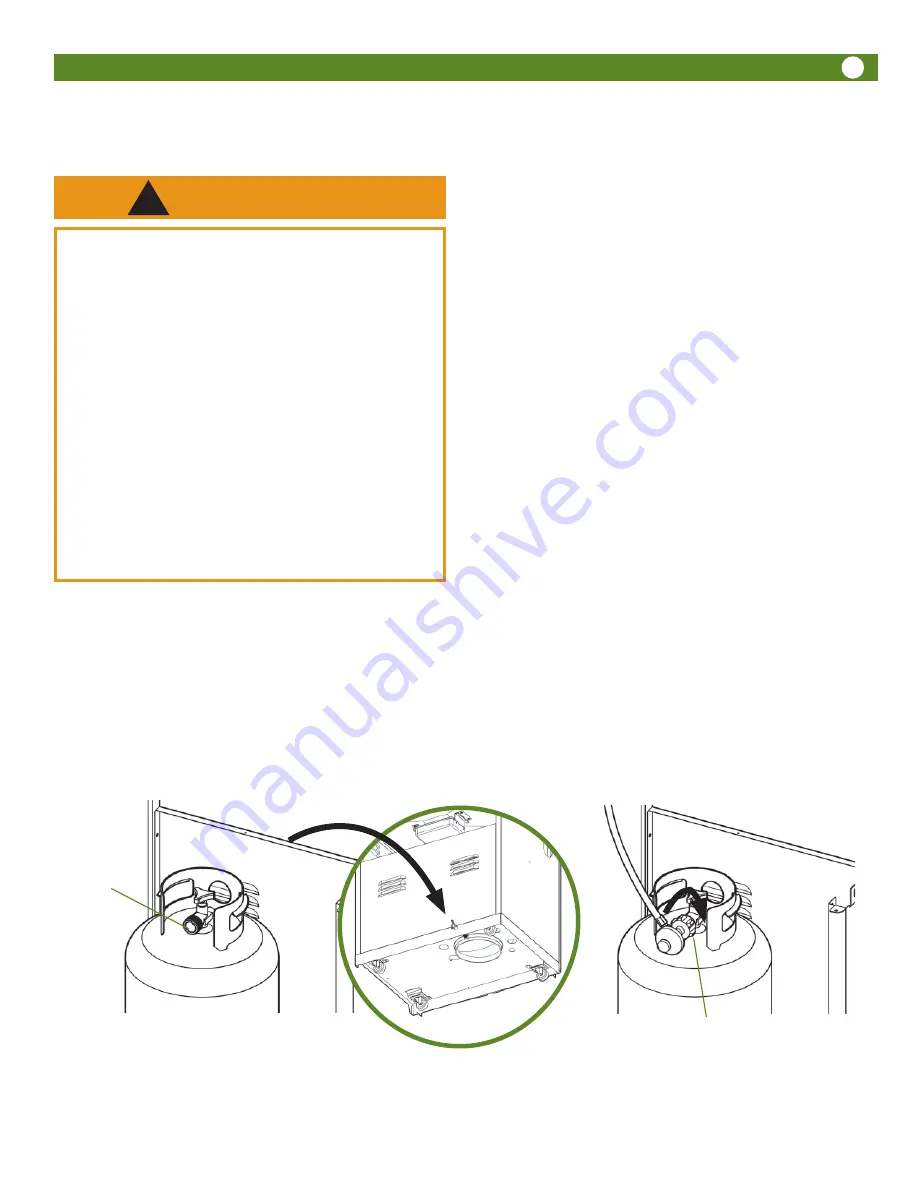

Connecting LP Gas Cylinder

1. Fill empty OPD LP Gas Cylinder at your local gas supplier.

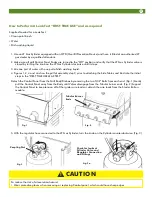

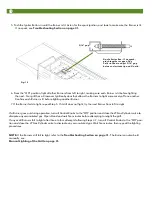

2. Place the LP Gas Cylinder in the large hole in the Bottom Panel inside the cabinet. Rotate the LP Gas Cylinder so the

Cylinder nozzle is toward the door opening for proper vapor withdrawl. Lock the LP Cylinder in place by tightening

wing bolt on the outside rear of the cabinet base so that it seats against the ring base of the LP Cylinder.

3. Remove the protective cap from the LP Gas Cylinder valve. (Save cap for re-capping.) Hold Regulator in a straight

line with LP Gas Cylinder valve so the connection does not cross thread. Insert Regulator Nipple into the LP Gas

Cylinder valve. Hand tighten coupling nut in clockwise direction. DO NOT USE TOOLS.

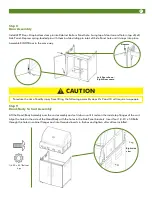

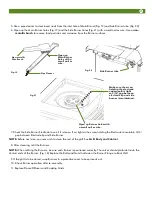

Disconnecting LP Gas Cylinder

1. Turn all Control Knobs to the “Off” position and turn the handle on the LP Gas Cylinder clockwise until it stops.

2. Turn coupling nut on regulator counterclockwise until regulator is released from the threaded LP Gas Cylinder

nozzle.

3. Place the protective cap over LP Gas Cylinder nozzle.

Hand-tighten coupling nut

in clockwise direction

Cylinder nozzle

faces out

toward door

Wing Bolt on outside

rear of cabinet base