24

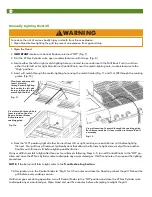

Manually Lighting the Grill

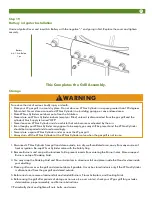

To reduce the risk of serious bodily injury or death from fire or explosion:

• Open Hood before lighting the grill to prevent an explosion from gas build-up.

WARNING

!

1. Open the Hood.

2.

IMPORTANT:

Make sure Control Knobs are turned “Off.” (Fig. 7)

3. Turn the LP Gas Cylinder valve open counterclockwise until it stops. (Fig. 8)

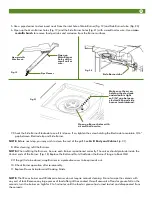

4. Locate either the left or right match-lighting hole you intend to use underneath the Grill Bowl. Push in and turn

either the far left or far right Main Burner Control Knob, near the match-lighting hole, counterclockwise to the

“High” position.

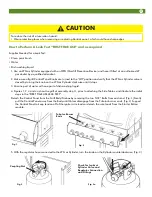

5. Insert a lit match through the match-lighting hole using the match holder (Fig. 11 and 11a) OR through the cooking

grates. (Fig. 12)

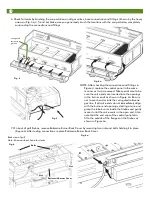

6. From the “Off” position, light all other Burners from left or right, making sure each Burner is lit before lighting

the next. Your grill has a Crossover Ignition System that allows the Burners to light successively off one another.

Confirm each Burner is lit before lighting another Burner.

If any or all Burners fail to light after three or four attempts following Steps 3-5, turn all Control Knobs to the “Off” po-

sition and close the LP Gas Cylinder valve to dissipate any accumulated gas. Wait five minutes; then repeat the lighting

procedures.

NOTE:

If the Burner still fails to light, refer to the

Troubleshooting Section.

7. After ignition, turn the Control Knobs to “High” for 3-5 minutes and close the Hood to preheat the grill. Preheat the

grill before every cooking session.

If a Burner goes out during operation, turn all Control Knobs to the “Off” position and close the LP Gas Cylinder valve

to dissipate any accumulated gas. Open Hood and wait five minutes before attempting to relight the grill.

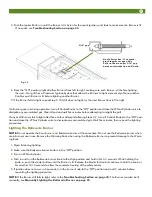

View from underneath.

Insert lit match

through match lighting

hole under the left side

burner table using the

match light holder

View of match through hole

from top side of burner.

Shown without Flavor

Activators and

cooking grids.

Fig. 11

Fig. 11a

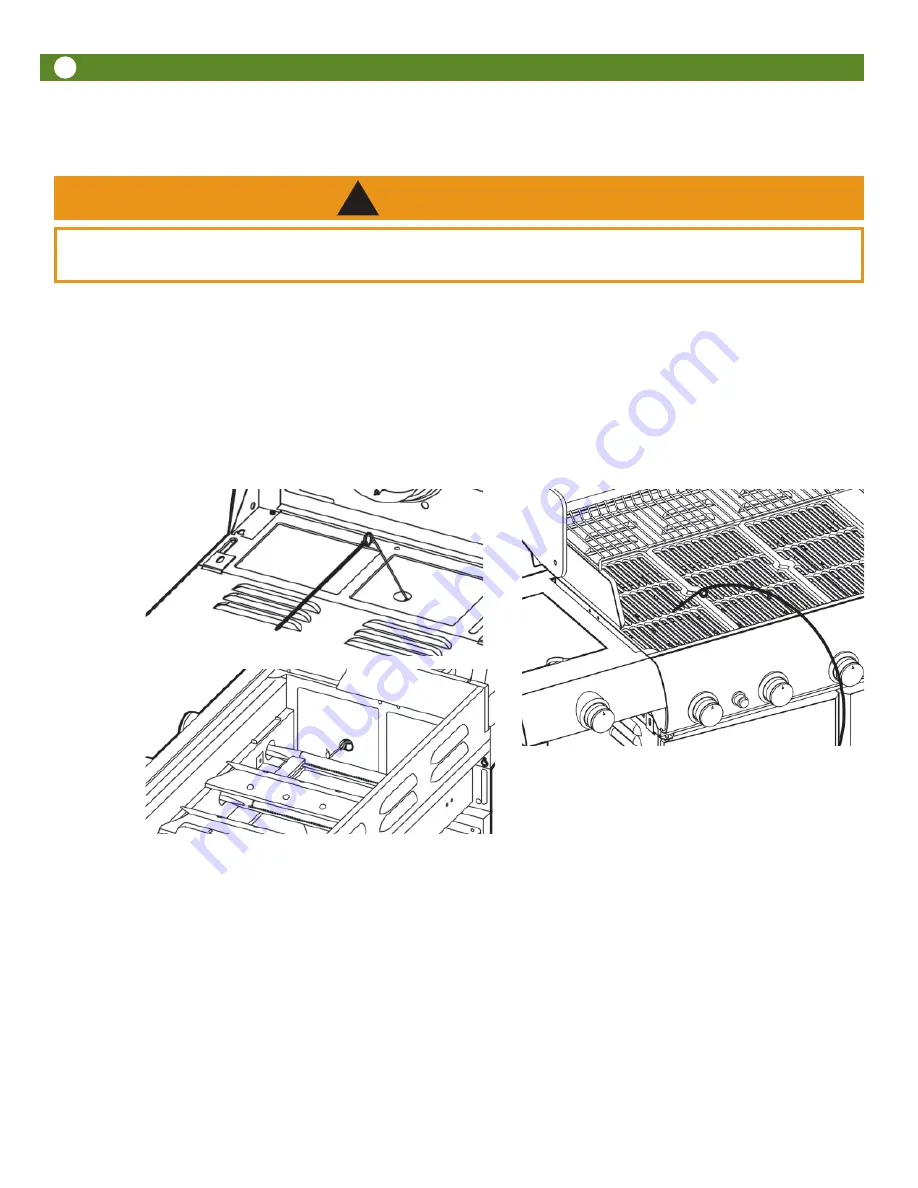

View of inserting lit match through the cooking grids.

Each burner may be lit in succession in this method if

necessary.

Fig. 12

Summary of Contents for Vantage 68R5A9SSS1

Page 37: ...37 ...