Exhaust and Debug

1. You need to exhaust and debug when you finish the lift installation.

2. Fill the oil tank with enough oil (not too full) and press the down-up button after connecting the

electric power, then the lift up and the hydro-cylinder works.

3. Make the lift continue to rise till to the highest position, and then not to press the button anymore

to avoid damaging the power unit.

4. Keep 10 seconds after rising to the highest position.

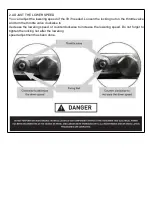

5. Pull out the lock release steel wire rope and press the down-handle which on the power unit,

then down the lift.

6. If there is any phenomenon such as jump or unbalance exist when the lift fall off,you should

adjust the balance wire rope repeat for many times, the car can be drove-on the lift when the

balance is guaranteed.

7. Start-up the motor and press the up-down button, then the lift rising, it’s normal for the slight

‘jump’ phenomenon from the cylinder.

Maintenance

1. Check if the support arm can be operated normally every class.

2. Check if the bolt and the hinge pin became free every class, tighten them when they are free.

3. Check if the safe device is reliable ever class.

4. Lubricate the slider which in the column and the entire axle chain every week (you can do this

depends on the reality).

5. Check if the foundation bolt is free or not, and tighten them when they are free.

6. Check if the column is deformed and perpendicular to the ground at regular intervals.

7. Check if the telescopic boom turns flexible and works reliable every class.

8. Check if the support pad is worn at regular intervals or it need to be changed.

9. Change the hydraulic oil every 500 working hours of the lift. You can change oil once within

1~1.5years when the lift is not used or not used frequently.

Summary of Contents for High-Lift Equipment YL-250W

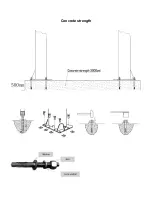

Page 13: ...oil tubes Two post Clear floor Lift Two post Base plate Lift ...

Page 14: ...Concrete strength ...

Page 16: ......

Page 17: ......

Page 20: ...4 Oil leakage outside 5 The sound is uncommon ...