Announcements for safe operation

(

You must read all of these content

)

1. Please read the manual and learn about the safety cautions before you use the equipment.

2. Be careful of your hands and feet, keep them away from the equipment to avoid harm.

3. Keep the environment tidy and clean, the mess workshop will cause accident.

4. Check the work environment of the equipment, not to expose it in the rain, not to use it in wet

environment, there must be air through and good sunshine.

5. The operator must be trained strictly, not allow the untrained person to touch and operate the lift

6. Use the lift follow the regulations, we are not responsible for the matters caused by the parts

which are not from our company

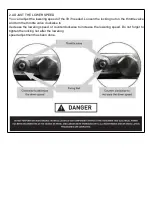

7. Protect the safe unlock carefully. Check if the safe unlock is reliable before operating.

8. Please attention to keep away when the vehicle is raised or laid down

9. There must be enough space in the workspace to keep away if the automobile which is on the lift

is dangerous.

10. The lift must be in mechanical lock position when you maintain the automobile.

11. The operators must have labor protection, they had better take on work shoes which with ferric

protection

12. To protect the operator avoid from electric hurt, the earth wire of the motor must be reliable.

13. Notice: There will be sparkle when the switch on and off during the lift working, so the lift can’t

be operated in the workspace where exists inflammable gas!

14. Notice: You must cut the power supply down before maintaining the electrical equipment of the

power unit

15. It’s necessarily to have a clean environment and good equipment maintenance. To lubricate

and maintenance correctly will help the equipment to reliable. The controlling handle and button

must be kept clean and dry and avoid oil dirt.

16. The operator must keep a clear mind during working and must put safety first.

17. Check if there is any damaged part or component. Attention to the synchronous condition

between the main support arm and the branch support arm, you must stop operating immediately if

you find there is anything abnormal condition, then examine and remove the faults.

18. Don’t to disassemble any parts or components related to safety. Otherwise, prohibit operating

the lift.

19. Please check if every part is normal and safe carefully (especially if the support pad is in the

right position and substance)

20. There not allow being any obstacles which stop the support arm down when to operate the lift to

fall off.

21. When the lift raise to the highest limit, the mechanical safe hook must be in position and secure

(there must be any sound)

22. When the lift raise to the highest limit, the operator should release the rising controlling button.

Summary of Contents for High-Lift Equipment YL-250W

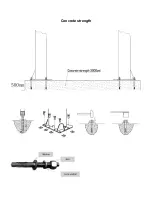

Page 13: ...oil tubes Two post Clear floor Lift Two post Base plate Lift ...

Page 14: ...Concrete strength ...

Page 16: ......

Page 17: ......

Page 20: ...4 Oil leakage outside 5 The sound is uncommon ...