21

EHT 50 - 150

Id.Nr.: 231769-9

10. Service Water Connection (pressure-proof)

E

Any warranty for our water heaters shall be rejected in case of use of unsuitable or inoperative sto-

rage connector fittings as well as an exceedance of the specified operating pressure.

All water heaters provided with a rating plate bearing the designation ‘nominal pressure 6 bar’

(atmospheric excess pressure or kp/cm2) are pressure-type storage tanks and can be connected on

a pressure-proof basis using a line pressure up to 5.5 bar (atmospheric excess pressure).

A pres-

sure reducing valve must be installed in the cold water supply line should the line pressure

be higher.

The water plumbing must only be implemented using a tested diaphragm safety valve or a dia-

phragm safety valve combination (connector fitting for pressure-type storage tanks)!

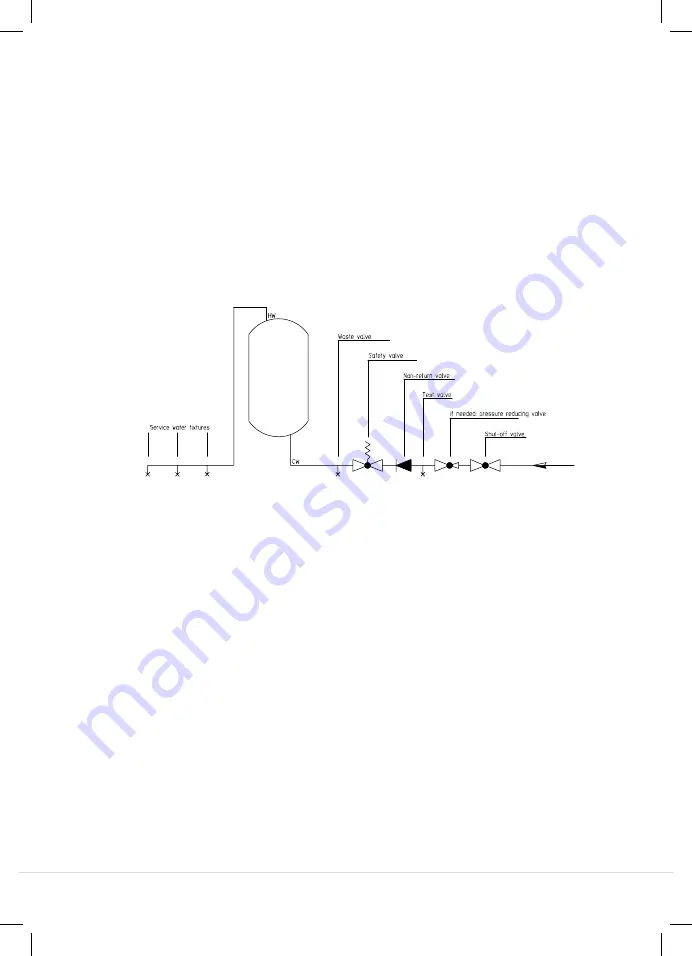

A safety valve combination consists of a shutoff, test, non-return, drain and safety valve with an

expansion water drain and is installed between the cold water supply line and the cold water supply

(blue) of the storage tank in the

order as drawn.

The following must principally be observed:

In order to ensure a flawless function of the connector fitting, it must only be mounted in frost-protected

rooms. The drain of the safety valve must be open and observable or the outlet pipe from the drop

collector (expansion water funnel) must lead into the sewer, so that neither frost nor clogging by dirt or

anything similar may cause any malfunction. Make sure that the drip cup is not blocked.

Furthermore, it must be observed that the drain pipe of the safety valve must be installed with a steady

downward inclination.

No shutoff valve or other throttling must be installed between the safety valve and the cold water supply

of the storage tank.

The safety valve must be set to a response pressure that is lower than the nominal pressure (6 bar) of

the storage tank. The cold water supply line must be rinsed out before the storage tank is connected

finally.

After completed plumbing and bubble-free filling of the storage tank, the connector fitting must be

checked for functionality.

a) In order to avoid a blockage of the venting facility of the safety valve due to furring, the venting

facility of the safety valve must be operated from time to time during operation of the system. It

must be observed whether the valve closes again after releasing the venting facility and whether

the water in place runs off completely through the funnel or the blow-off pipe.

Summary of Contents for EHT Series

Page 39: ......