© Austria Email AG

id.: 17-14-35-1251-08 | 02.2016

6.2

Checks before starting

Before starting the device, the following must be checked:

-

The hot water tank must be filled with water and ventilated.

-

All the seals must be tight.

-

All protection elements must be functioning.

6.3

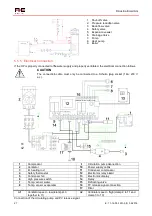

Connection of the HP to the voltage power grid

The device is equipped with a power cord with a plug. Before starting, the power cable must be plugged into

a socket with a voltage of 230 V a.c.

After plugging it in, the start-up sequence will be shown in the display. The settings are displayed one after

the other.

If the start sequence is not shown, contact customer service.

6.4

Operation

If the heat pump is properly connected to the voltage and water sup

the operating programme selected or >P1< appears on the screen, as well as all parameters and their

values. 30 seconds after the electric connection, the system starts and begins to heat the water.

The heat pump switches on. After reaching the pre

switches off automatically. If the water cools down by 5°C, to 47°C, the heat pump switches back on. The

switch-off temperature can be selected by the user but is limited

regulator blockade). Water heating is limited to 60°C and cannot be adjusted. The ambient air temperature at

which the system switches to the replacement heat source has already been set to 0°C. This temperature

can be adjusted by the user as desired (following instructions).

6.5

Settings

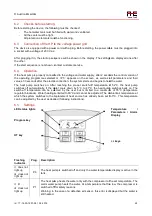

LED status lights

Program key

HT key

Flashing

indicator

Prog. Description

☼ does not

light up

does not

light up

P0

The heat pump is switched off and only the water temperature display is active in the

tank.

☼ lit

does not

light up

P1

The heat pump heats the water only with the compressor to the set temperature. The

warm water pump heats the water. At a temperature that too low, the compressor is

switched off for safety reasons.

Warning: In the case of a defective air sensor, this erro

still heated.

Before starting the device, the following must be checked:

The hot water tank must be filled with water and ventilated.

All protection elements must be functioning.

Connection of the HP to the voltage power grid

The device is equipped with a power cord with a plug. Before starting, the power cable must be plugged into

a socket with a voltage of 230 V a.c.

up sequence will be shown in the display. The settings are displayed one after

If the start sequence is not shown, contact customer service.

If the heat pump is properly connected to the voltage and water supply, after 2 seconds the control version of

the operating programme selected or >P1< appears on the screen, as well as all parameters and their

values. 30 seconds after the electric connection, the system starts and begins to heat the water.

switches on. After reaching the pre-set switch-off temperature of 52°C, the heat pump

switches off automatically. If the water cools down by 5°C, to 47°C, the heat pump switches back on. The

off temperature can be selected by the user but is limited to a maximum of 55°C (temperature

regulator blockade). Water heating is limited to 60°C and cannot be adjusted. The ambient air temperature at

which the system switches to the replacement heat source has already been set to 0°C. This temperature

justed by the user as desired (following instructions).

The heat pump is switched off and only the water temperature display is active in the

The heat pump heats the water only with the compressor to the set temperature. The

warm water pump heats the water. At a temperature that too low, the compressor is

switched off for safety reasons.

Warning: In the case of a defective air sensor, this error is displayed but the water is

5.2.

24

The device is equipped with a power cord with a plug. Before starting, the power cable must be plugged into

up sequence will be shown in the display. The settings are displayed one after

ply, after 2 seconds the control version of

the operating programme selected or >P1< appears on the screen, as well as all parameters and their

values. 30 seconds after the electric connection, the system starts and begins to heat the water.

off temperature of 52°C, the heat pump

switches off automatically. If the water cools down by 5°C, to 47°C, the heat pump switches back on. The

to a maximum of 55°C (temperature

regulator blockade). Water heating is limited to 60°C and cannot be adjusted. The ambient air temperature at

which the system switches to the replacement heat source has already been set to 0°C. This temperature

Temperature

/

Parameters / Alarm

Display

+/- keys

The heat pump is switched off and only the water temperature display is active in the

The heat pump heats the water only with the compressor to the set temperature. The

warm water pump heats the water. At a temperature that too low, the compressor is

r is displayed but the water is