10

ALTERNATOR OUTPUT TEST

F

This test accurately measures the maximum output of

the alternator under maximum load conditions. This

information provides the basis for further charging

system tests. It also detects the presence of an open

diode which causes an output loss of several amps

and can cause the failure of other diodes.

A FURThER LOOk...

ALTERNATOR TERMINALS

DELCO REMY- 10 SI

“BAT” = Alternator output to + battery.

“No. 1” = Battery current to rotor winding.

“No. 2” = Alternator output from battery.

DELCO REMY- 10 Dn

“Bat” = Alternator output to + battery.

“GRD” = Additional ground

“R” = Indicator lamp

“F” = Rotor winding to regulator

MOTORCRAFT

-Rear terminal

“BAT”= Alternator output to + battery

“STA” = Starter to various units including indicator lamp.

“FLO” = Rotor winding to regulator

“GRD” = Ground

SIDE TERMInAL:

Same except “STA” connects to rectified alternator

output.

CHRYSLER:

“BAT” = Alternator output to + battery.

“GRD” = Ground

(2) “FLD” = Connects to 2 insulated brushes

1. Tester hook-up see instruction “D” for hook-up.Turn

ignition on and read key draw before starting.

2. Start engine, idle at approximately 2000 rpm or to

manufacturers test rpm.

3. Slowly apply load. Adjust load to obtain maximum

alternator output on the amps scale. Do not allow

voltage to drop below 12 volts or 24 volts on 24

volt systems. Use vehicle accessories if necessary to

aid in applying load.

4. Check stator diode LED: If LED is on continuously, diode

or stator is bad. Replace alternator. A bad or “open”

diode or open stator windings can cause a slight drain

on alternator output as well as causing other diodes to

fail. This could eventually result in a failed regulator or

dead battery.

NOTE: LED may flash during transient loading, only a

steady light indicates a defect.

5. Read maximum amp output of alternator and remove

load. Add key draw reading to alternater output.

Output should be within 10-15% of manufacturers

specifications.

n

If output is O.K. go to voltage

REGuLATOR TEST

STEp H.

n

If output is low on the external regulator go to

REGuLATOR BYpASS TEST STEp G

n

If output is low on the internal regulator replace

alternator.

NOTE: Check alternator for correct size pulley. (Too large

may account for low output.)

n

Inductive Amp Probe in many cases might have to

be placed on the output wire of the alternator to read

maximum output.

STATOR

DIODE

A

M

P

S

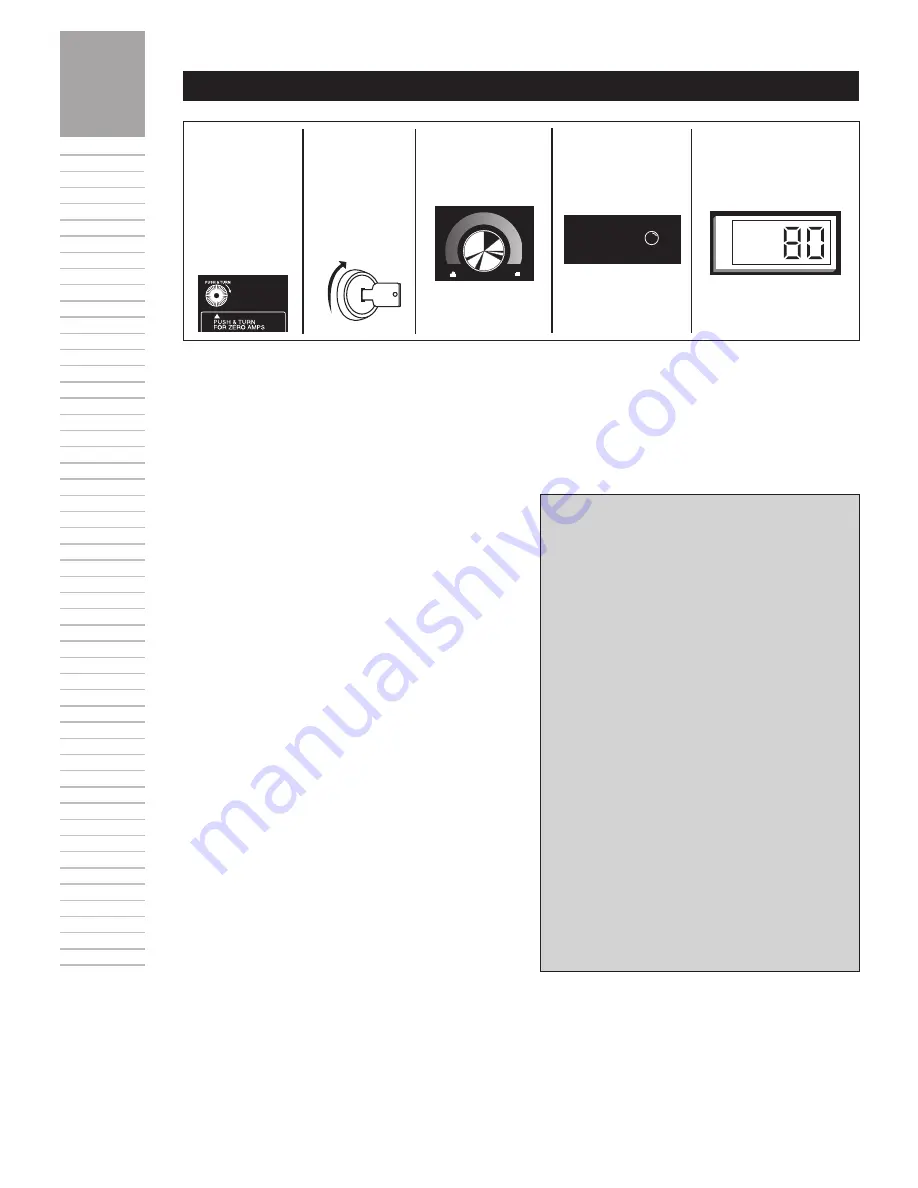

1. HOOk-up

TESTER

2. ZERO

AMMETER

(IF nECESSARY)

4. SLOWLY

AppLY LOAD

5. CHECk

STATOR DIODE

LED

6. READ MAX.

AMp OuTpuT OF

ALTERnATOR. THEn

TuRn OFF LOAD.

3. TuRn On

kEY AnD

READ kEY

DRAW (AMpS)

THEn START

EnGInE.

See “D” Tester Hook-

up

OFF

LOAD