10

7. Tool Bits

Use provided 4.0mm Allen wrench to unbolt tool bit holders. Then replace worn tool bits

with new bits by using flat-head screwdriver. NEVER operate the lathe with a worn or broken

tool bits. It can not only cause poor cut but also tool bit holders to contact the rotor or

drum surface. It may cause damage to the rotor, drum or even tool bit holders. Replace

worn or broken tool bits immediately with manufacturer’s recommended carbide inserts.

DBL-STAR STD uses TPGX110308 HTi10 carbide inserts made by Mitsubishi Materials.

8. Chip Deflector

When turning the disk, it is ESSENTIAL to attach chip deflector in order to achieve smooth cut. It

also dampens vibration and noise effectively while machining. You may experience poor-cut

without Chip Deflector so make sure to use it at all times. Chip Deflector is a consumable item and

has a limited lifetime. Replace as necessary to ensure smooth operation. To purchase replacement

pad, contact your local dealer or distributor.

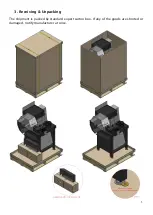

Step.1

Step.2

Step.1

Place pads right on top

of the tool bits to ensure

best performance

Summary of Contents for DBL-STAR STD/MINI

Page 8: ...8 Machine Dimensions ...

Page 23: ...23 1HP Geared Motor ...

Page 25: ...25 LED Safety Guard ...

Page 26: ...26 Twin Cutter Assembly ...