9-16

FITTED EQUIPMENT

Draining the water heater

Switch off power to water pump (main or

pump switch).

Open hot water taps in kitchen and

bathroom.

In order to check the water that is flowing out,

place an appropriate container (capacity 10

litres) beneath the drain valve (FrostControl)

drainage muff (x).

Turn the rotary switch on the drain valve by

180º until it engages, whereby the push

button moves out and the drain valve opens.

Check whether all of the water in the boiler

(10 litres) has been drained into the container

via the drain valve.

There shall be no claims under guarantee for

damage caused by frost!

Maintenance

Only original Truma parts may be used for

maintenance and repair work!

The materials in the device that come into

contact with water are drinking water safe.

Bio-film, deposits and limescale must be

removed using chemicals to protect the unit

from infestation by micro-organisms. Only

Chloride-free products must be used in order

to prevent damage to the unit.

The effectiveness of the use of chemicals to

combat micro-organisms in the unit can be

increased by heating the water in the boiler

to 70ºC at regular intervals.

To do this, on the control panel, select Gas

Operation, then select Summer Operation

60ºC.

Note:

Once the water in the boiler has

reached a temperature of 60ºC, the burner

will switch off. The unit must stay switched on

for at least 30 minutes and no warm water

may be removed. The residual heat in the

heat exchanger will heat the water up to

70ºC.

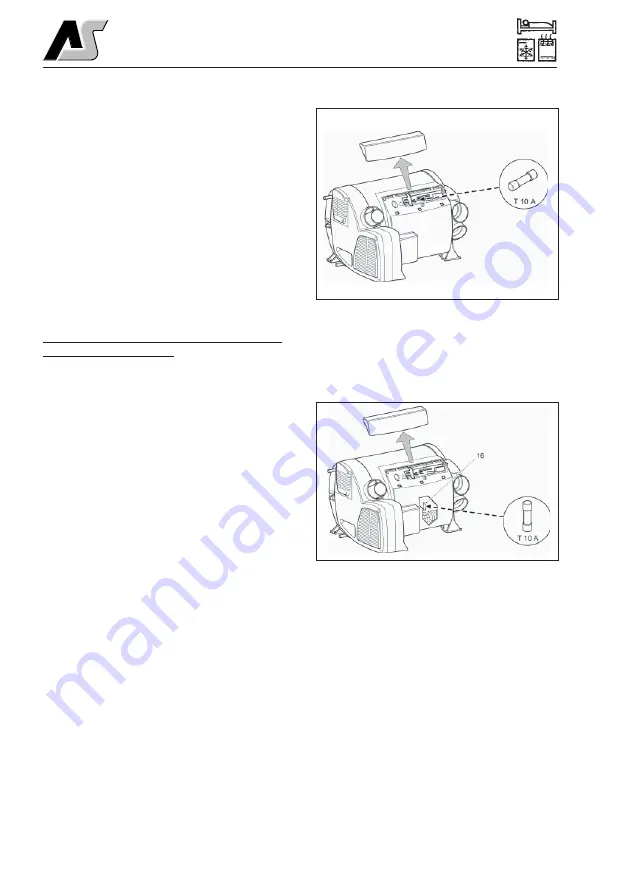

Fuses 12V

The fuse is in the electronics beneath the

connection cover. Replace the unit’s fuse

only with an identical fuse.

Device fuse: 10A - slow - (T 10A).

Fuses 230V

CAUTION:

The fuse and the power supply

lines must only be replaced by an expert!

WARNING: The unit must be

disconnected from the mains (all poles)

before opening the electronic housing

lid.

The fuse in the power electronics (16)

beneath the electronic housing lid.

This fine fuse must always be replaced with

a fuse of the same type: 10A, slow,

interrupting capacity “H”.

Summary of Contents for Topaz

Page 6: ...1 4 ...

Page 10: ...2 4 MOTORHOME CODE ...

Page 16: ...5 2 ARRIVAL AT SITE ...

Page 24: ...6 8 SAFETY SECURITY ...

Page 46: ...7 22 CONNECTION OF SERVICES 12V 230V WIRING DIAGRAM ...

Page 73: ...9 23 FITTED EQUIPMENT 1 2 4 3 5 6 ...

Page 74: ...9 24 FITTED EQUIPMENT 7 8 10 9 11 12 ...

Page 78: ...9 28 FITTED EQUIPMENT ARRANGEMENT OF EQUIPMENT TOPAZ ...

Page 82: ...9 32 FITTED EQUIPMENT NORMAL SEATING ASSEMBLY TOPAZ ...

Page 83: ...9 33 FITTED EQUIPMENT DOUBLE BED ASSEMBLY TOPAZ ...

Page 84: ...9 34 FITTED EQUIPMENT SINGLE BED ASSEMBLY TOPAZ ...

Page 106: ...12 10 SERVICE DETAILS ...

Page 108: ...13 2 NOTES Designed and Printed by Preset Graphics Tel 01332 549278 MY 2016 Ref 21465 ...