Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 43 of 101 Page issue 5.1, dated 10.06.14

4. Fuel supply on

5. Altimeter adjusted

6. Rudder control effective

7. Wind direction known

8. Minimum equipment functioning. Minimum flight equipment is Compass, Altimeter,

Airspeed indicator, slip indicator, Engine rpm gauge, rotor rpm gauge.

9. Good practice is that the canopy is closed and LOCKED.

TO START ENGINE

Commence start

After turning the master switch on, the ‘Gen’ light will come on (alternator not charging),

and the boost and TCU electronic check lamps will light for about 2 secs (if Turbo engine).

The fire warning lamp will also pulse red three times to confirm correct system function

and then go off if the system functions normally. If not it will stay solid red (system fault), in

which case stop and investigate. Before starting the Turbo engine, listen for fuel pump

noise, and then switch on second pump, and listen for noise increase. If either pump does

not run, STOP and investigate. Second pump may be left on, or turned on when ready for

flight.

The second pump should be used as a backup for take off and landing only. It is not

required for normal flight use.

The low voltage warning light (marked ‘Low Volt’) may also come on, especially if all

electrical equipment is turned on. It comes on when battery voltage drops below 11.8v,

and goes off at 12,5v. The external lights and the 12v socket are turned off by a load

shedding relay when the lamp is lit. Check that it goes off when the engine is run up to

4,000rpm. If is doesn’t, then do not fly, investigate, as the alternator will be unable to

maintain the aircraft electrical requirement. Note that if there is insufficient voltage this

load shedding relay will stop ancillary services from working (ie 12v socket and lights)

whether or not the engine is running.

Once started the ‘Gen’ light will go off, indicating the alternator is working. In low light

conditions it may be seen to flicker gently, both at idle and in flight. This is normal. If the

light remains on during engine warm up (normally conducted at 2,000 to 2,500rpm), then

this indicates failure of the engine alternator and/or regulator. Stop and investigate.

If there is no immediate response when turning the key to start the engine (engine doesn’t

turn over) and/or the instrument lamps dim significantly then engine start should be

aborted and the battery voltage checked for charge state. If charged suitably, and

cranking doesn’t work, then either the fuse protecting the starter circuit is blown, or the

starter motor has failed. Investigate, and resolve.

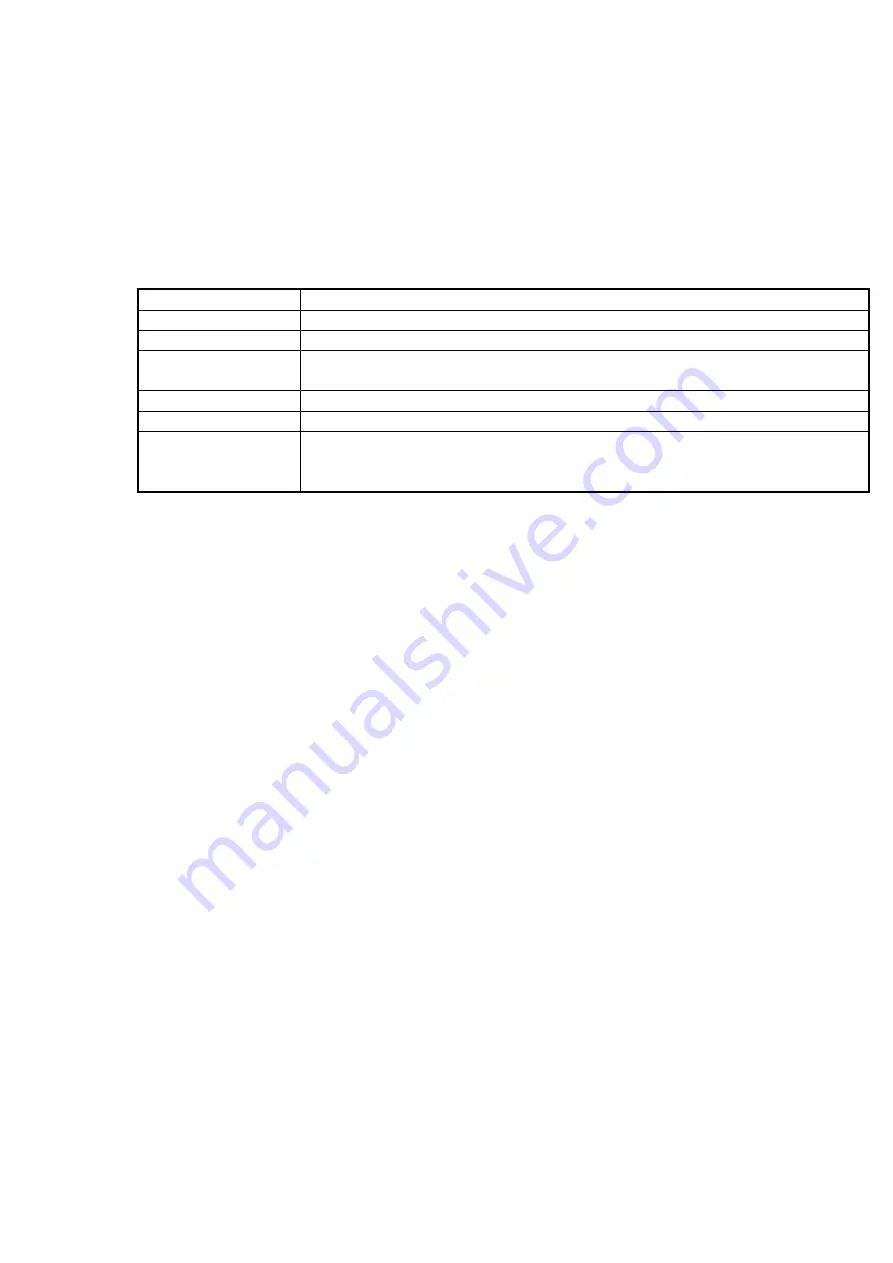

Main switch

ON (generator warning light on)

Choke

Engage (until engine warm and/or will run without choke.)

Throttle

Closed

Propeller

Danger area – keep clear!

If IVO-prop fitted ensure FINE pitch (see section 9 of this document)

Brake operation

Lock brakes on

Magneto switches

On (both)

Starter

Operate until engine starts. Take care! Do not run the starter

continuously for more than 10secs, and no more than 30 secs in 2 mins

– damage to the battery or starter may result.