Copyright © 2005 Automated Equipment LLC All Rights Reserved

11

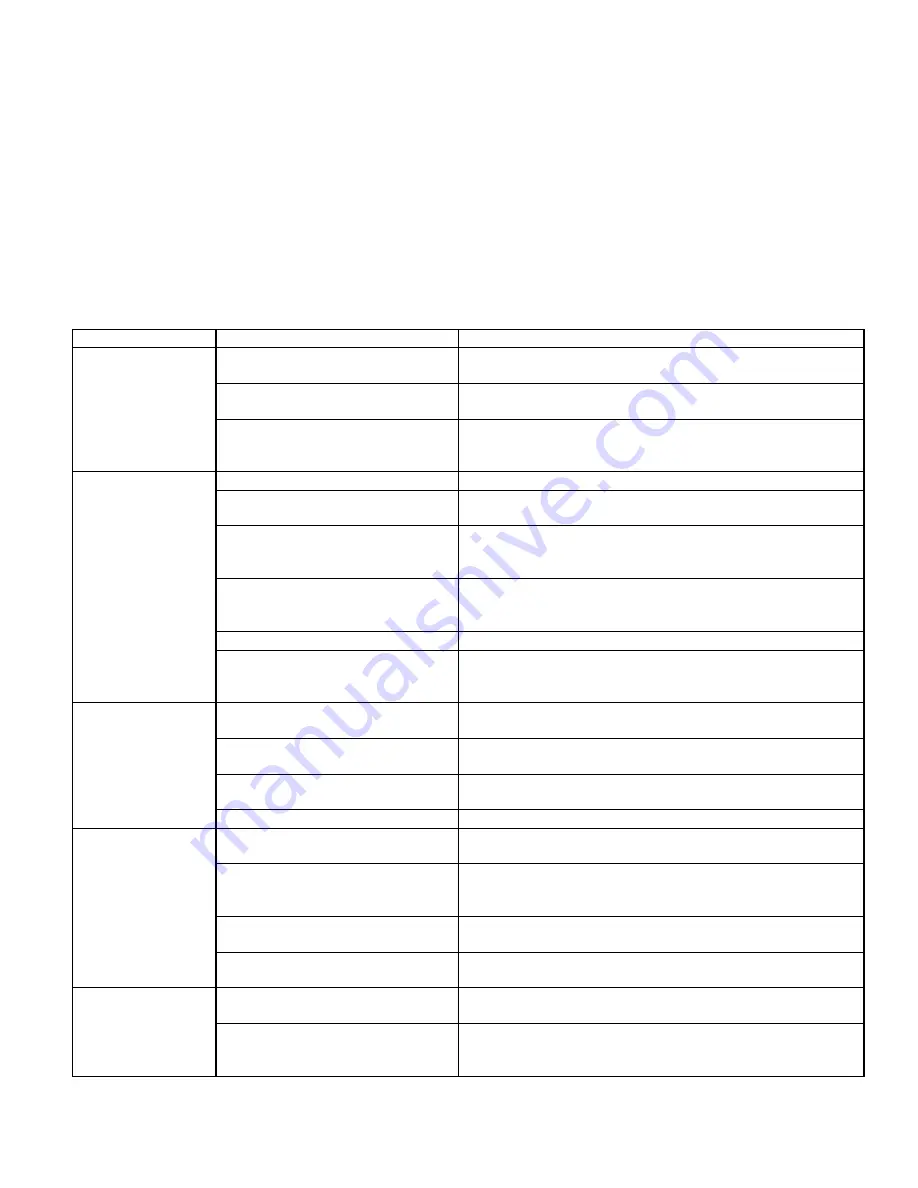

TROUBLESHOOTING

The status of the Arch Fry Dispenser is displayed in the Start/Reset Button light. When the Hopper is filled and

operating normally, the Start/Reset Button remains steadily illuminated. System Errors appear as a flashing green

light on the Operator Panel. System Errors are a result of incorrectly assembling the Arch Fry Dispenser, or an

interruption in the normal operation.

In the following charts, the PROBLEM columns contain a list of problems that may occur, the PROBABLE CAUSE

column describes why the problem may have appeared; and the CORRECTIVE ACTION column describes the action

that must be taken to eliminate the problem. If after performing the procedure listed under CORRECTIVE ACTION

you have not corrected the problem, call AELLC Service for assistance.

NOTE: Press the Start/Reset Button after correcting the problem.

PROBLEM

PROBABLE CAUSE

CORRECTIVE ACTION

Restart Button is

flashing slowly.

Hopper is empty

Fill the Hopper with Fries.

Fries have formed a “bridge” over

the drum.

Remove the Hopper Lid and re-distribute the Fries inside.

Hopper Drum is not locked onto

the shaft.

Remove the Hopper Lid and Fry Diverter. Turn the

Dispenser Drum, while applying pressure and slide it fully

onto the shaft. Re-install the Fry Diverter and Hopper Lid.

Restart Button

Compressor is not running

Check that compressor has power and is turned on.

begins flashing

immediately when

Air Line is not connected to the

Dispenser.

Connect the Air Line to the Dispenser.

Dispenser is

turned on.

Compressor has not been

allowed to charge before Air Line

was connected

Disconnect the Air Line from the Dispenser. Wait until the

compressor reaches full pressure (compressor will turn

itself off). Reconnect Air Line.

Air Pressure is below 60 PSI (4.0

bar)

Adjust the compressor to maintain between 90 and 120

PSI (6 and 8 bar). If you need assistance, contact AELLC

Service

Pressure switch is faulty.

Contact AELLC Service

There is an air leak.

Check the main Air Line, Compressor, and Arch Fry

Dispenser for leaks. If you are unable to find it, or need

assistance repairing it, contact AELLC Service

Basket Loads are

consistently light

Basket Load Offset switches were

not set properly.

Verify proper switch settings. Re-position the switches if

necessary.

or heavy.

The Hopper is touching the

Accumulator Doors.

Re-assemble the Hopper. No objects, other than Fries,

may touch the Accumulator Doors.

The Load Cell is improperly

calibrated.

Refer to the Load Cell Calibration procedure in the non-

scheduled maintenance section.

The Load Cell has malfunctioned.

Contact AELLC Service.

Basket Loads

suddenly change.

Fries have formed a “bridge” over

the drum.

Remove the Hopper Lid and redistribute the Fries.

The Hopper is empty.

Refill the Hopper with Fries. Remove any empty Fry

Baskets from the Lower Guide and place them on the

Upper Guide.

The Fry Diverter is not properly

installed.

Remove and re-install the Fry Diverter.

The Hopper is touching the

Accumulator Doors.

Re-assemble the Hopper. No objects, other than Fries,

may touch the Accumulator Doors.

Dispenser Drum is

not rotating

The accumulator doors are full.

The Dispenser Drum will rotate only when the accumulator

doors require more Fries.

Hopper is empty (Restart Button

is flashing slowly).

Fill the Hopper with Fries. The Dispenser Drum will rotate

when the next empty Fry Basket is cycled through the

Upper Guide.