23

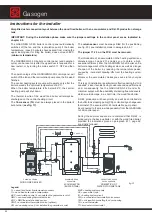

Instructions for the installer

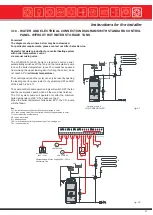

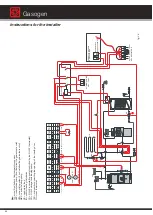

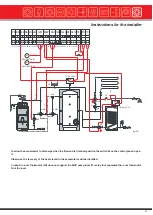

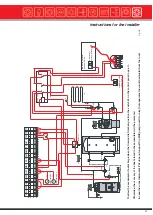

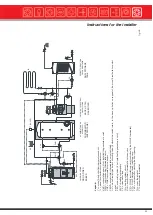

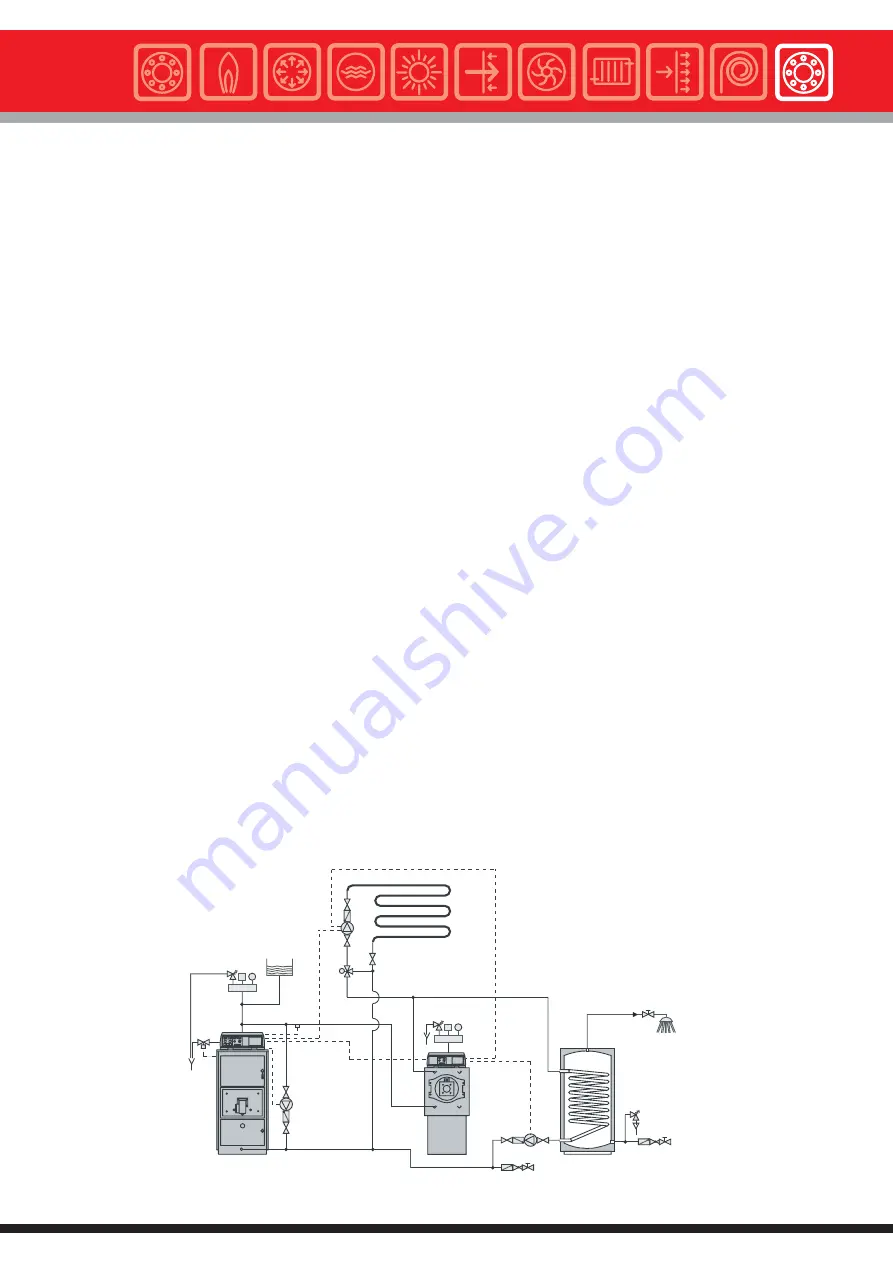

3.11 - WATER AND ELECTRICAL CONNECTION DIAGRAMS WITH OPTIONAL CONTROL

PANEL BOARD, WITHOUT HOT WATER STORAGE TANK

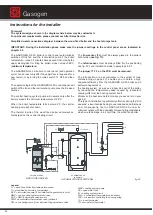

Foreword!

The diagrams shown here below may be customized.

For particular requirements, please contact our After Sales Service.

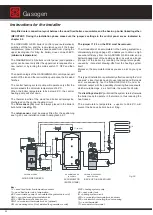

The GASOGEN G3 2S boiler’s standard control panel

automatically switches off the fan and the recirculation pump if

the boiler temperature, (once 30 minutes have passed from

closing the upper loading door for firing the boiler), does not

reach 65°C (

minimum temperature

).

In this case, or when the wood finishes, the auxiliary boiler will

start firing automatically, provided the selector 22 of the panel

board is on (

0

) and the burner switch 23 is in pos.

II

, 30 minutes

after the wood fired boiler temperature falls below 60°C.

The wood fired boiler’s door must be kept closed.

The wood fired boiler, in this case, will be excluded and it will

be possible to restart it after opening the door in order to load

new wood.

If the burner switch 23 is always kept on pos.

0

), the back-up

boiler’s burner will be always excluded.

Obviously, to permit operation of the back-up boiler, the control

panel must be in the ON position.

The GASOGEN G3 2S boiler’s control panel (and operation

cycle) can be reset only after the upper door is reopened for a

new restart, or by turning the mains switch 11. OFF and then

ON.

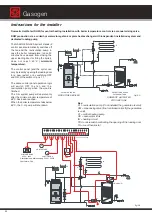

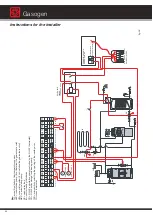

Central heating installation with temperature controlled via a motorized mixing valve.

DHW is produced via a coiled hot water storage tank or plate heat exchanger with an independent installation system

and dedicated loading pump.

The two boilers are hydraulically connected in series, with the wood fired boiler system flow connected to the oil/gas

fired boiler’s system return.

There is no need to install a diverting valve, or DHW storage tank loading pump; the DHW tank can be incorporated in

the oil/gas fired boiler.

In the summer, DHW production can be supplied only by the oil/gas fired boiler.

The heating circuit water flows through both the boilers and, in this case, the heat losses are very important.

IMPORTANT: During the installation phase make sure the jumpers’ settings in the control panel are as indicated in

chapter 5.2.

The logic operation of the GASOGEN G3 2S boiler’s control

panel, will switch off the fan and the recirculation pump once

the wood finishes.

The central heating system pump will operate only after the

boiler exceeds the minimum temperature of 65°C.

When the boiler temperature falls below 65°C, the central

heating pump will shut down.

The D.H.W. storage pump will operate in priority compared to

the central heating pump.

The

flow sensor (Tc)

must be always placed in the boiler’s

bulb holder (

see fig. 17

).

D.H.W. production will be given priority via the storage tank

loading pump (PR), controlled by a changeover thermostat.

The eventual D.H.W. recirculation pump must be connected to

the mains independently from the GASOGEN G3 2S boiler’s

control panel.

During the summer season we recommend that DHW is

requested via the back-up boiler, or with the wood fired boiler,

provided the indications given on paragraph 6.11, page 59,

are strictly followed.

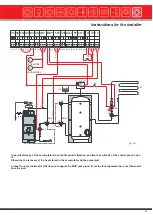

CALDAIA A LEGNA

KKP

VE

MKP

IR

Tc

PR

PRODUTTORE ACQUA

CALDA SANITARIA

B

AB

VM

A

CALDAIA DI SOCCORSO

GASOLIO/GAS

M

fig. 25

WOOD FIRED BOILER

BACK UP BOILER

DOMESTIC HOT

WATER STORAGE TANK

Summary of Contents for Gasogen

Page 1: ...Wood Fired Boiler Gasogen 29 93kW Installation and Servicing Manual ...

Page 66: ...Gasogen notes ...

Page 67: ...notes ...