26

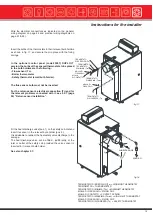

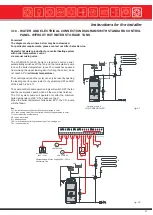

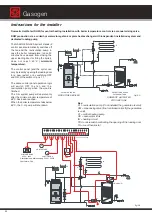

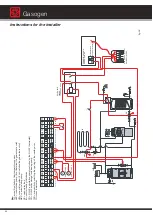

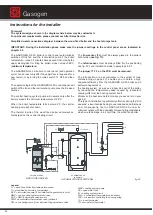

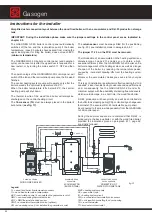

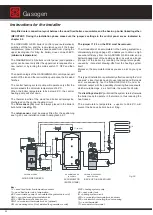

Instructions for the installer

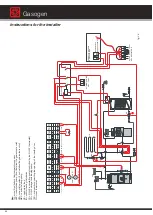

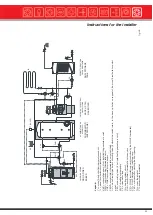

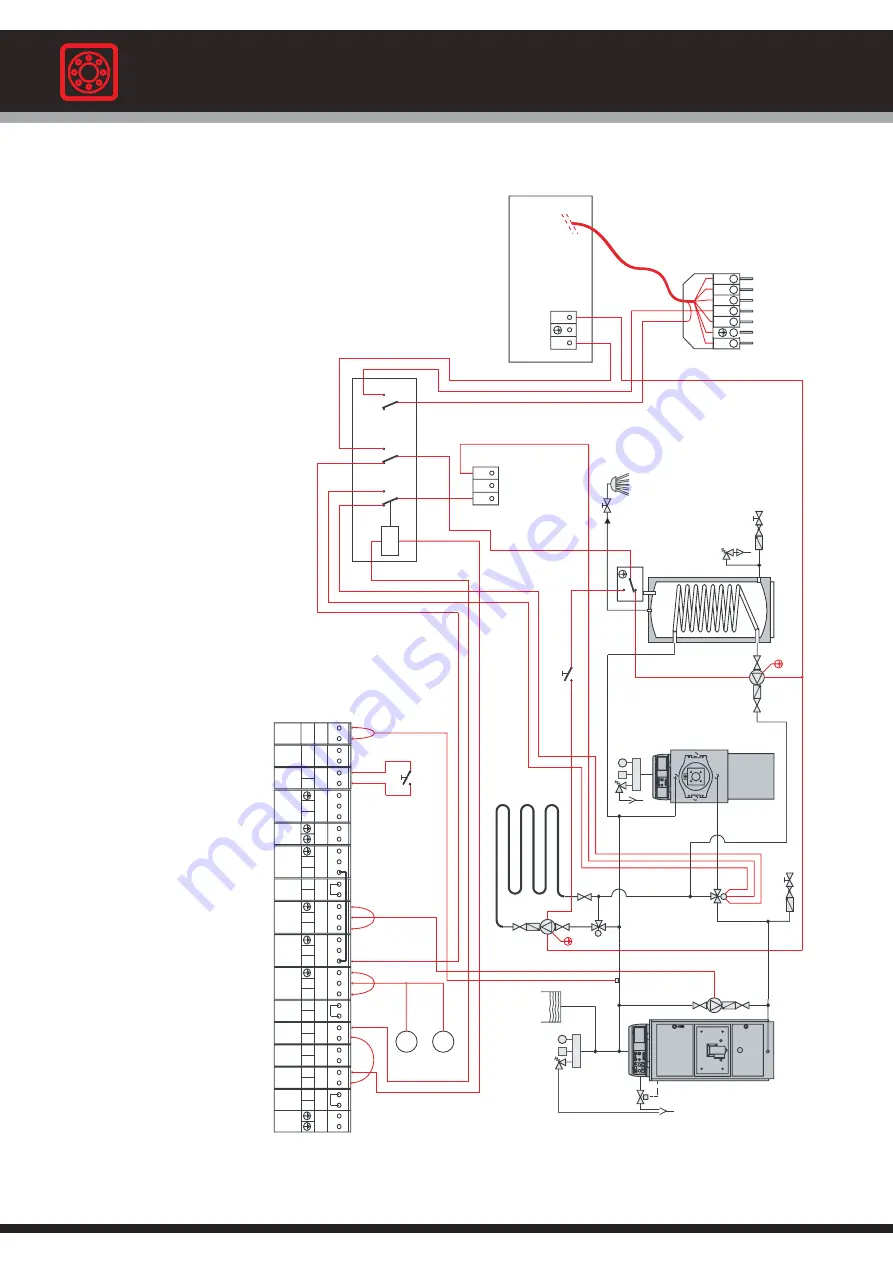

KKP

VE

MKP

IR

Tc

PR

B

AB

UV

A

B

AB

VM

A

M

M

15

17

19

21

23

27

30

16

18

20

22

24

28

31

29

32

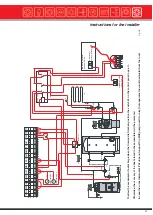

PE

BV

AG

W

RAB

L

1

L

1

L

1

L

1

L

1

NN

L

1

NN

1

1

1

1

1

1

1

GM

MKP

33

34

L

1

L

1

1

TAMB

35

38

36

39

37

40

L

1

L

1

N

1

1

KKP

MAXP

PE

BS

SK

25

26

L

1

1

1

41

42

L

1

46

47

TKS

1

1

TR

48

49

1

TC

50

51

43

44

45

L

1

1

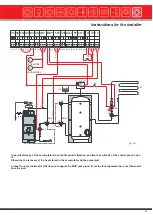

NETZ

N

N

L

1

L

1

VENTILAT

ORE

1

C

1

TKS

M

27

27

28

28

29

29

-

-

-

-

30

3334

35

-

-

5051-

C

1

TA

33

34

35

--

ALIMENTAZIONE

2

3

0

V~5

0H

z

C

1

2

30

9

6

3

A1

A2

RELÉ

A

3VIE

8

5

2

7

4

1

L1

N

20

24

N

L1

T1

T2

S3

B4

ALLA

PRESA

A

7

POLI

DEL

BRUCIA

T

ORE

L1

N

P

ANNELLO

CALD

AIA

A

GASOLIO/GAS

Alimentazione

pompa

principale

20

24

30

5051-

VENTILAT

ORE

2

M

27

28

29

--

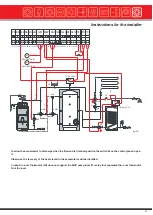

fig.

28

Ke

y

:

Tc

=

w

ood

fired

boiler’

s

flo

w

temper

ature

s

ensor

KKP

=

recirculation

pump

(if

not

installed

the

guar

antee

is

v

oid)

VM

=

z

one

mixing

v

alv

e

(if

not

installed

the

guar

antee

is

v

oid)

MKP

=

c

entr

a

l

heating

pump

VE

=

open

w

a

ter

tank

IR

=

c

entr

a

l

heating

installation

PS

=

D

.H.W

.

recirculation

pump

(controlled

b

y

the

D

.H.W

.

ther

mostat)

PR

=

D

.H.W

.

s

tor

age

tank

loading

pump

TKS

=

micros

witch

controlling

the

opening

of

the

loading

door

T

A

=

room

ther

mostat

Gasogen

Summary of Contents for Gasogen

Page 1: ...Wood Fired Boiler Gasogen 29 93kW Installation and Servicing Manual ...

Page 66: ...Gasogen notes ...

Page 67: ...notes ...