34

Instructions for the installer

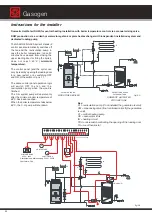

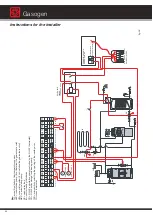

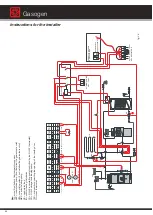

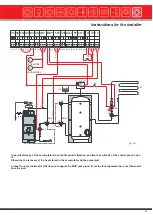

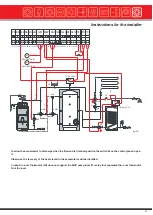

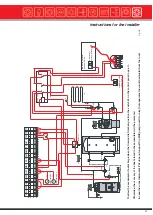

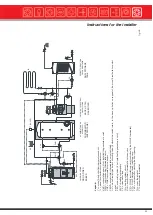

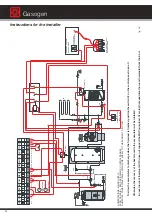

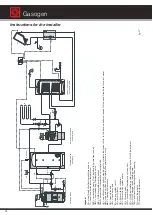

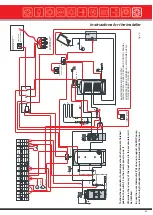

Simplified water connection layout between the wood fired boiler, accumulator and DHW production, and the back-up

boiler linked together (see figs. 35 and 36)

IMPORTANT: During the installation phase make sure the jumpers settings in the control panel are as indicated in

chapter 5.2.

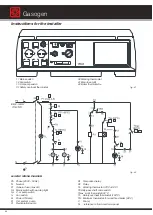

The GASOGEN G3 2S boiler’s control panel automatically

switches off the fan and the recirculation pump if the boiler

temperature, (once 30 minutes have passed from closing the

upper loading door for firing the boiler), does not reach 65°C

(

minimum temperature

).

The GASOGEN G3 2S boiler’s control panel (and operation

cycle) can be reset only after the upper door is reopened for a

new restart, or by turning the mains switch 11. OFF and then

ON.

The operation logic of the GASOGEN G3 2S control panel, will

switch off the fan and the recirculation pump once the fire wood

finishes.

The central heating system pump will operate only after the

boiler exceeds the minimum temperature of 65°C.

When the boiler temperature falls below 65°C, the central

heating pump will shut down.

The thermal inertia of the wood fired boiler will always be

discharged on the central heating circuit.

The

flow sensor (Tc)

must be always placed in the boiler’s

bulb holder (

see fig. 17).

The

return sensor

must be always fitted (for the positioning

see fig. 20); see installation mode in paragraph 5.5.7.

The jumper 71-72 on the PCB must be removed.

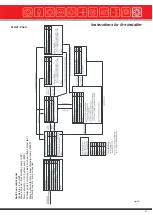

The introduction of an accumulator in the system of (see sizing

on page 27), enables you to obtain a high seasonal efficiency

from the GASOGEN G3 2S boiler and a better management of

the heating system, as well as a longer life span of the boiler,

by reducing the temperature peaks, caused by inconstant

drawing-offs from the heating system itself.

Moreover, the accumulator makes you save a lot on your gas

bill.

This type of installation is particularly effective during the “mid

seasons”, since it avoids having to use reduced wood fire loads

and, consequently, fire the GASOGEN G3 2S under its

minimum output, with the possibility of creating flue condensate,

which would damage, in a short time, the wood fired boiler.

The

diverting valve (UV)

, will direct the system returns towards

the boiler ready to operate in that moment, thus reducing the

heat losses.

The temperature of the accumulator, superior to 50-55°C, will

prevent the back-up boiler’s burner firing.

La produzione di a.c.s. sarà gestita in priorità tramite la pompa

di carico bollitore (PR) comandata da un termostato in scam-

bio, la pompa di ricircolo dell’impianto sanitario dovrà essere

collegata alla rete elettrica indipendentemente dal pannello

strumenti della GASOGEN G3 2S.

Durante il periodo estivo si consiglia di produrre l’a.c.s. con la

caldaia di soccorso, oppure con la caldaia a legna, seguendo

scrupolosamente le indicazioni al cap. 6.11 a pag. 59.

D.H.W. production will have priority and be controlled via the

tank’s loading pump (PR), controlled by a changeover

thermostat. The eventual D.H.W. recirculation pump shall

be connected to the mains independently from the GASOGEN

G3 2S control panel.

During the summer season we recommend that D.H.W. is

produced with the back-up boiler, or with the wood fired boiler,

provided the indications given on paragraph 6.11, page 59,

are strictly

followed.

Gasogen

Summary of Contents for Gasogen

Page 1: ...Wood Fired Boiler Gasogen 29 93kW Installation and Servicing Manual ...

Page 66: ...Gasogen notes ...

Page 67: ...notes ...