50

Instructions for the installer

5.4.4 - OIL/GAS BOILER OPERATION (see Step 4, Step 6, page 47)

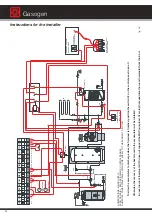

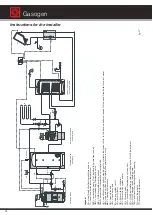

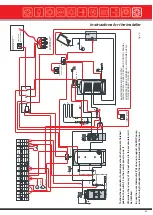

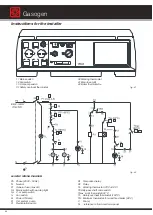

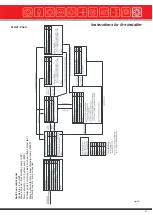

In installations with a back up oil/gas boiler (hydraulically connected in parallel), the burner is switched ON via the potenti al free

contact BV, if this has been integrated in the burner’s electrical wiring by the installer; in paragraph 3.11 an auxiliary circ uit

diagram is proposed for controlling: - the C.H. pump, controlled by the back-up boiler’s control panel, - the diverting valve, which

allows the water flow to be diverted from the wood fired boiler to the auxiliary one – the back up boiler’s (oil/gas) burner.

In case there is no wood, the back-up boiler is automatically fired according to the steps seen in the previous paragraph.

On the contrary, if the user needs to operate the back- up boiler without waiting the time foreseen by the Timer 1, he only nee ds

to press the keys 22 and 23 respectively in position “I” and “II”.

5.4.5 - DOMESTIC HOT WATER PRODUCTION

Summer mode for only D.H.W, production is not advisable and could, if not controlled properly, cause the intervention

of the safety overheat thermostat (see paragraph 6.11).

In case the user needs to produce D.H.W, to create these installation systems it is necessary to refer to the principle scheme s

shown on pages 30, 35 and 38.

When designing the system for installing the wood fired boiler and the back up boiler, the engineer has to take into considerat ion

the increase in output necessary for D.H.W. production; normally, in fact, D.H.W. production has priority over the request for heat

and therefore the sizing of the D.H.W. storage tank volume has to be customized to the user’s needs and at the same time it has

to be calculated when dimensioning the boiler in order to avoid long waiting times for the changeover from D.H.W. mode to CH

mode.

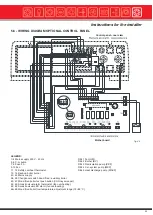

As far as D.H.W. production is concerned, the electrical connection to the control panel is described in the WATER AND

ELECTRICAL CONNECTION DIAGRAMS in paragraphs 3.11 and 3.12.

Gasogen

Summary of Contents for Gasogen

Page 1: ...Wood Fired Boiler Gasogen 29 93kW Installation and Servicing Manual ...

Page 66: ...Gasogen notes ...

Page 67: ...notes ...