8

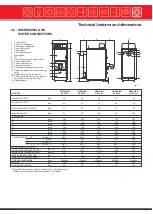

Technical features and dimensions

3

8

11

1

2

14

13

17

12

15

7

18

M

R

9

10

16

4

6

5

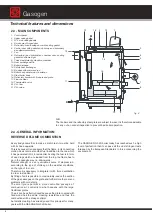

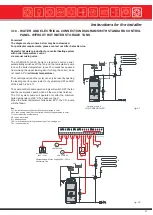

2.3 - MAIN COMPONENTS

1. Control panel

2.

Upper casing panel

3.

N° 2 side casing panels

4. Smoke proof hinged door

5.

Refractory-lined loading door with sealing gasket

6.

Central door with gasket and primary and secondary

air adjustment screws

7.

Fan

8.

Refractory-lined combustion chamber door, sealing

gasket and flame sight

9.

Thick steel plated combustion chamber

10. Heat exchange baffle

11. Boiler drainage

12. Safety heat exchanger

13. By-pass with command rod

14. Boiler body mineral wool insulation

15. Steel boiler body

16. Refractory burner with fire bars and grate

17. Flue chamber

19. Thermostatic valve

M C.H. flow

R

C.H. return

fig. 2

N.B.:

The fire bars and the refractory steel grate are subject to wear; it is therefore advisable

to carry out an annual inspection to prevent bad boiler operation.

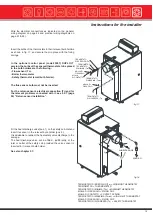

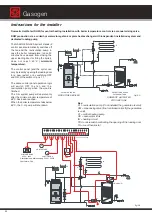

2.4 - GENERAL INFORMATION:

REVERSED FLAME COMBUSTION

Every body knows that to make a match last it must be held

with its head upwards.

This is because it is necessary that the flame, in its convective

motion, does not meet another fuel in addition to the one which

it has generated it. As in residential heating the fuel is in form

of wood logs which are loaded from the top, the flame has to

go in the opposite way, i.e. downwards.

Natural draught is a very variable source of depression,

according to the type of chimney, on the weather conditions,

on the type of fuel, etc.

Therefore it is necessary to integrate it with forced ventilation

in order to stabilize it.

By fitting a fan it is possible to considerably reduce the section

of the gas passages on the grate and furthermore there are no

problems with cold starts.

The small grate permits a more controlled passage of

combustion air, contrarily to what happens with the large

traditional grates.

The air can be perfectly dosed because the grate covered with

fired wood has the same crossing resistance and thus the

combustion will be always optimal.

Automatic Heating has already used this principal for many

years with the GASOGEN G3 2S boiler.

The GASOGEN G3 2S boiler today has reached such a high

level of perfection that it can pass all the most stringent tests

foreseen by the European Standards in force concerning the

environment.

Gasogen

Summary of Contents for Gasogen

Page 1: ...Wood Fired Boiler Gasogen 29 93kW Installation and Servicing Manual ...

Page 66: ...Gasogen notes ...

Page 67: ...notes ...