9

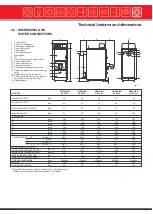

Technical features and dimensions

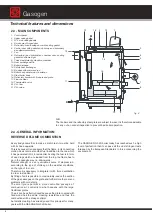

M

R

8

7

9

10

1

2

3

4

5

6

fig. 3

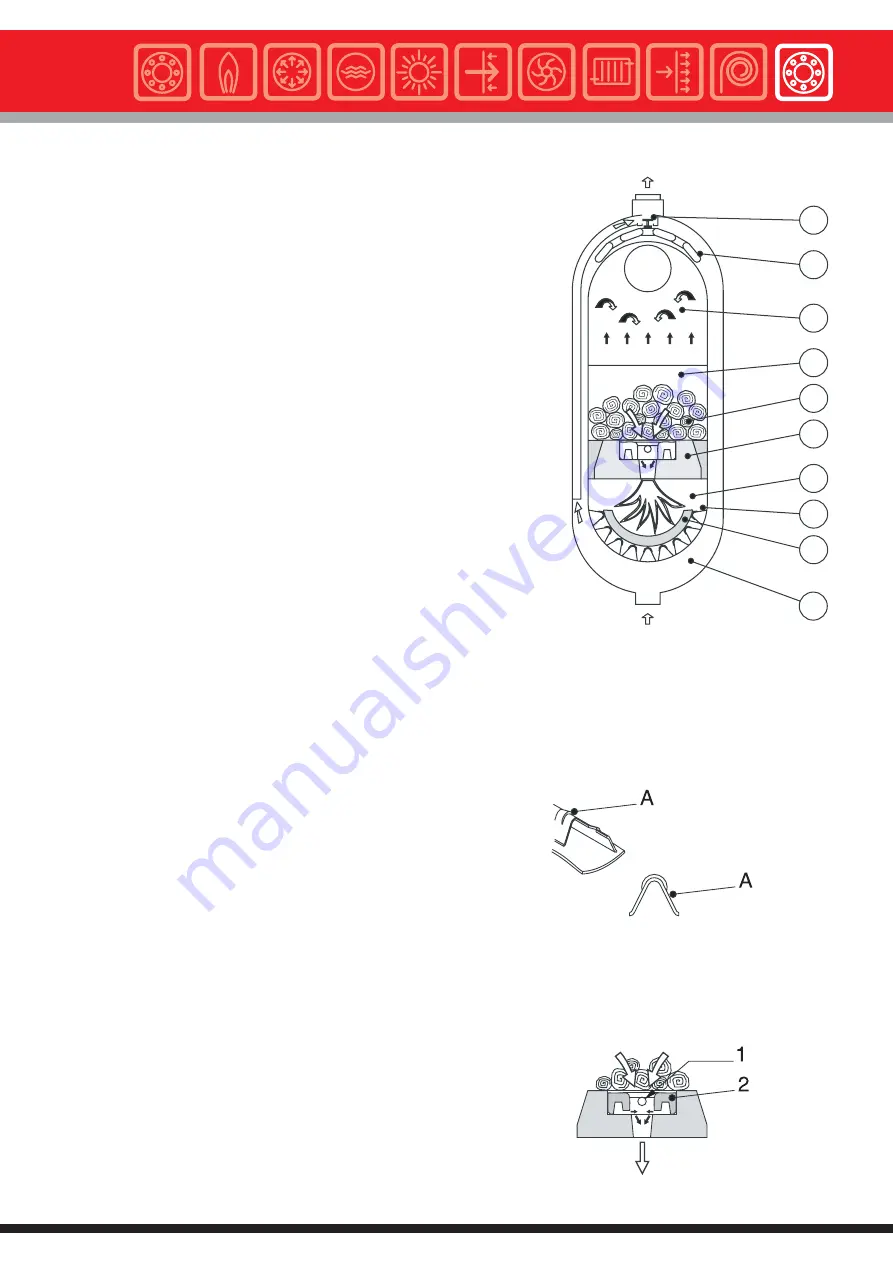

GASOGEN G3 2S - BOILER CONSTRUCTION

The boiler body is made of two oval elements, one placed inside

the other, so as to form a water cavity (fig.3).

The large fire box , in its rear wall, has a refractory insulation,

which is particularly resistant to heat and mechanical stresses,

in order to keep the by-pass zone dry in every working

condition.

We can distinguish the following parts (fig.3):

1. Fire box, drying area

2. Gasification zone

3. Embers zone

4. Refractory burner

5. Combustion chamber

6. Heat exchange surface

7. Refractory steel cradle

8. Boiler water

9. Thermostatic system

10. Safety heat exchanger

M C.H. system flow

R C.H. system return

GASIFICATION ZONE (2)

The gasification takes place In the lower part of the fire box .

It is very important that the gasification is as regular as possible,

so as not to overburden the burner with gas. The gasification

speed depends on the quantity of the wood and the dimensions

of the drying area. Generally, it is better to use large logs if

they are dry and small logs if the wood is wet . The quantity of

primary air, proportional to the delivered output, is regulated

via the adjustment system.

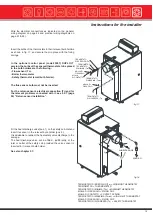

EXCHANGE SURFACE (6)

As the boiler operates on wood, and because the sulphur

concentrations are not very high , it is important to obtain very

low smoke temperatures in order to increase the water

efficiency.

To obtain this Automatic Heating has opted for an exchange

surface with dry smoke passes (fig. 4), which have already

been extensively tested in oil fired boilers working at low water

temperature, thus permitting low smoke temperatures without

danger of condensate forming.

The surfaces of the dry passages “A” (fig. 4) have had incisions

made on them in order to avoid dilatation problems.

The solid residues of combustion (ashes), which lie on the

high temperature refractory-lined cradle (fig. 3, pos. 7,) will

become with time always lighter until they will be dragged by

the gas speed and will deposit themselves in the lowest area

of the rear smoke chamber, from which they will be removed

during the cleaning operation.

REFRACTORY BURNER (4)

The burner is made up of refractory stone (fig. 3, pos. 4).

This stone has an oval central opening through which the flame

passes.

The embers lie directly on the main stone which divides the

fire box from the lower combustion chamber.

Furthermore the main refractory stone has a rectangular seat

in which the opportunely grooved cast iron fire bars are placed

(fig. 5, pos. 2), which receive the secondary air from a front

distributor.

The embers are prevented from falling by cylindrical pieces of

refractory steel. The combustion gases, poor in oxygen and

fig. 4

fig. 5

1. Metallic grate

2. Cast iron fire bars

Summary of Contents for Gasogen

Page 1: ...Wood Fired Boiler Gasogen 29 93kW Installation and Servicing Manual ...

Page 66: ...Gasogen notes ...

Page 67: ...notes ...