NAM-TRS372-MT-EN-C

p26/38

The information in this document is the property of Automatic Systems and is confidential. The consignee withholds from using it for anything other than the use of the products or the execution of the

project to which they belong and withholds from communicating it to third parties without prior written agreement from Automatic Systems. Document subject to change without prior notice.

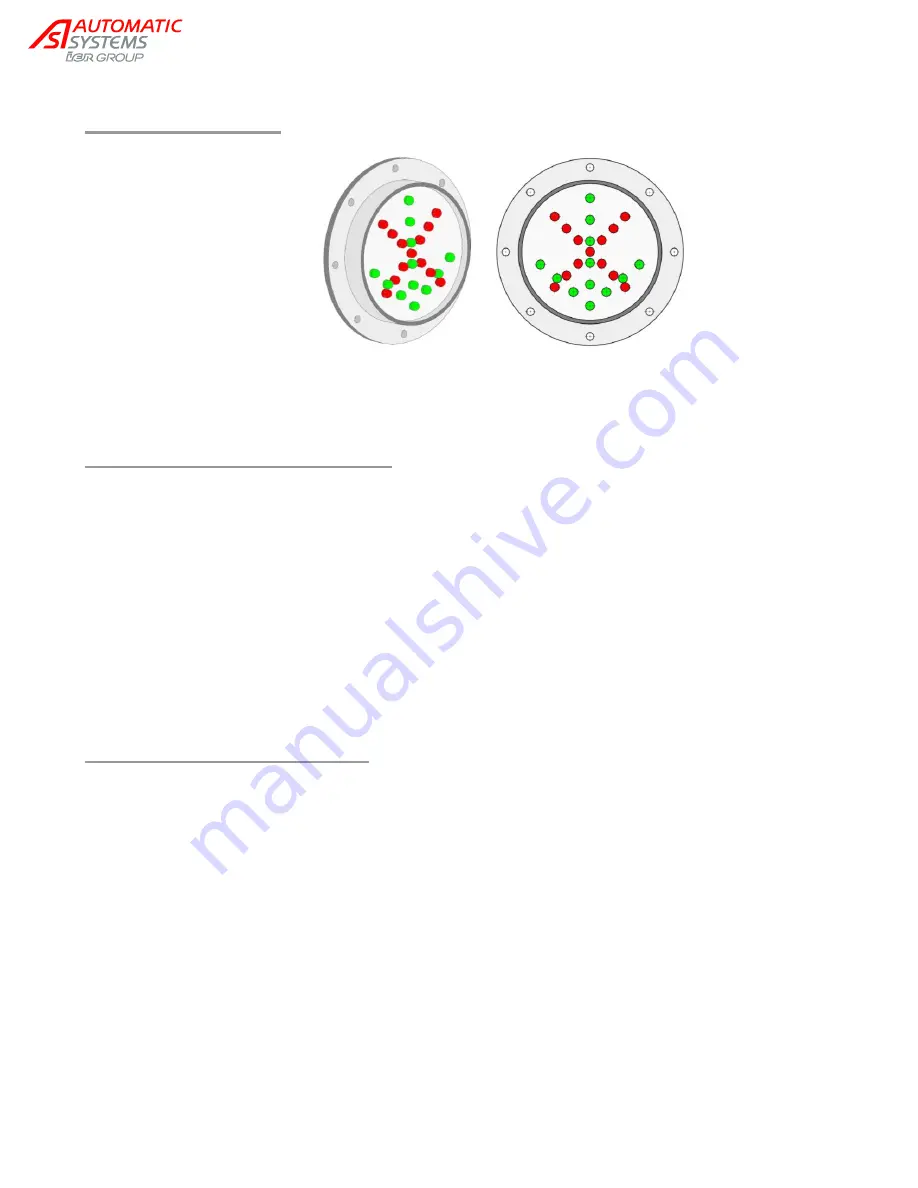

3.10. Pictograms

Pictograms mounted on the housing can operate according to the two (2) modes described below, depending

on the electrical connections and their parameterization in the control board.

3.10.1. Orientation pictograms

Orientation pictograms indicate the status of the passageway, and thus help to orientate the user

approaching the turnstile.

Apparatus Out of Service:

X

in both directions

Apparatus In Evacuation:

in both directions

Apparatus In Service (for each direction of passage):

-

Controlled Mode:

-

Free Mode:

-

Locked Mode:

X

3.10.2. Function pictograms

Function pictograms indicate the functional status of the passageway to the user (for each direction):

passage authorized or unauthorized.

Locked Mode:

X

Free Mode:

-

If passage under way in opposite direction:

X

-

If not:

Controlled Mode:

-

At rest: Pictogram turned off or

X

, according to the status of "Idle Fct Picto" parameter of

"Options" menu.

-

If passage under way in opposite direction:

X

-

If passage authorization: