22

GDO-9

Owner Installation Instructions

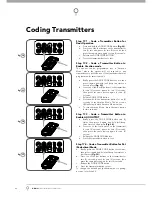

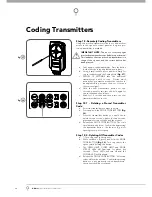

Step 17.1 - Code a Transmitter Button for

Door Operation

Press and hold the DOOR CODE button

(Fig. 32)

.

Press one of the four buttons on the transmitter for

two (2) seconds, pause for two (2) seconds, then

press the same button again for two (2) seconds.

Release the DOOR CODE BUTTON.

Press the transmitter button to test.

Step 17.2 - Code a Transmitter Button to

Enable Vacation mode

The opener can be programmed into a “Vacation

Mode” where the opener will not respond to any

transmitter except the button of the transmitter that was

programmed for vacation mode.

Briefl y press the DOOR CODE button once, then

press it again and hold (will beep two times on

second press

(Fig. 33)

).

Press one of the four (4) buttons on the transmitter

for two (2) seconds, pause for two (2) seconds,

then press the same button again for two (2)

seconds.

Release DOOR CODE button.

Press and hold the transmitter button for six (6)

seconds to set Vacation Mode. The door code

LED will stay lit while Vacation Mode is active.

To reset Vacation Mode, press the same button

for two seconds.

Step 17.3 - Code a Transmitter Button to

Enable AUX OUTPUT

Briefl y press the DOOR CODE button two (2)

times, then press it again and hold (will beep

three times on third press

(Fig. 34)

).

Press one of the four buttons on the transmitter

for two (2) seconds, pause for two (2) seconds,

then press the same button again for two (2)

second.

Release the DOOR CODE button.

Press the transmitter button to test.

Step 17.4 - Code a Transmitter Button for Pet

(Pedestrian) Mode

Briefl y press the DOOR CODE button three times,

then press it again and hold (will beep four times on

fourth press

(Fig. 35)

).

Press one of the four buttons on the transmitter for

two (2) seconds, pause for two (2) seconds, then

press the same button again for two (2) seconds.

Release the DOOR CODE button.

Press the transmitter button to test.

To change the default pet (pedestrian) door opening

position, refer Step 24.

a.

b.

c.

d.

a.

b.

c.

d.

e.

a.

b.

c.

d.

a.

b.

c.

d.

Coding Transmitters

32

fi g

33

fi g

34

fi g

35

fi g