7

www.automationdirect.com/click-plc

3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

1-800-633-0405

C2-02CPU Quick Start Guide

Copyright© 2020,

Automationdirect.com

Incorporated/All Rights Reserved Worldwide

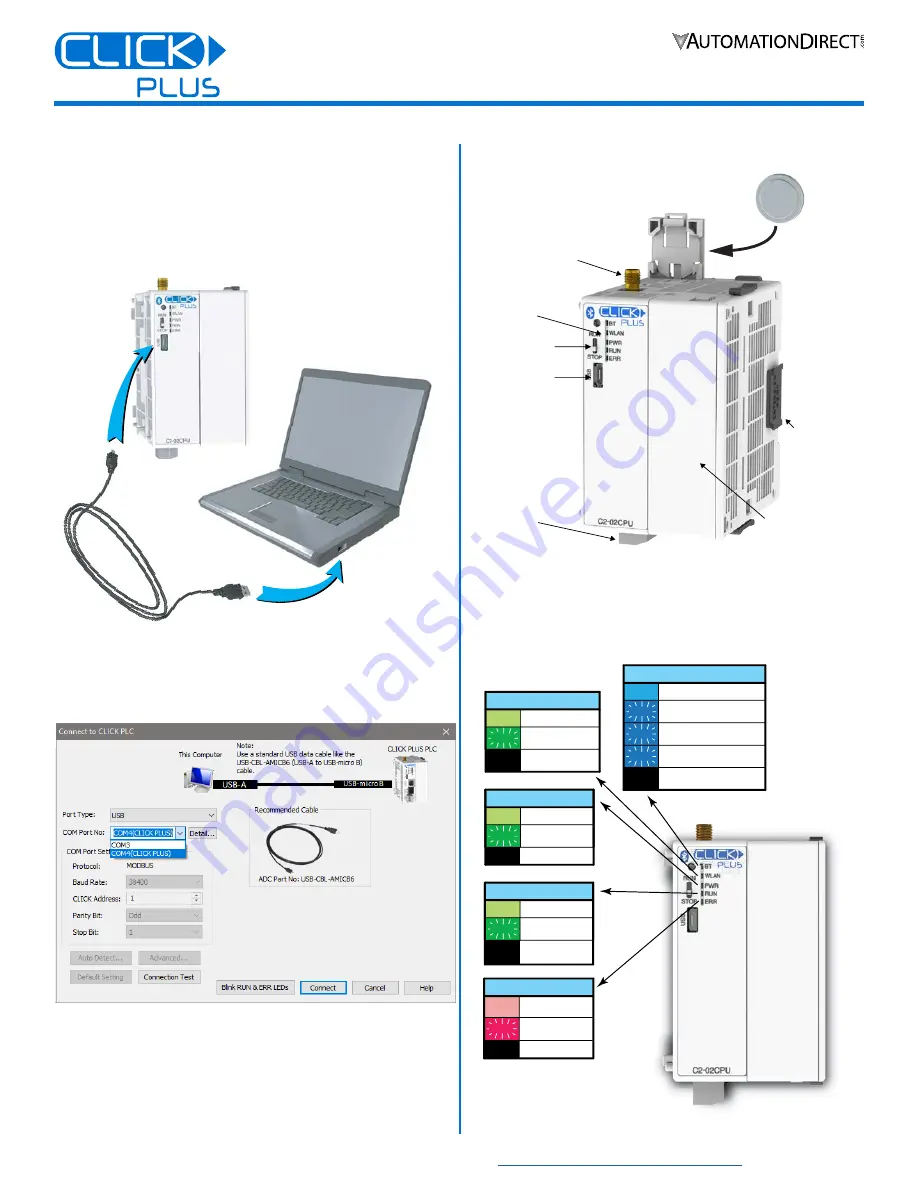

External Features

CPU is shown with op�onal C2-FILL Op�on Slot Cover installed.

Mode

S

W

S

t

a

t

us LED

s

mic

ro US

B

O

p

�o

n

Sl

ot

(f

or O

p

�on Slot Module)

(Device)

Ex

p

a

nsion

Conn

ec

to

r

W

LAN/BLE Ex

t

ernal A

nt

enna Port

Pow

er

Block

T

er

min

al

B

a�er

y

(

O

p

�on)

C2-02CPU

C2-02CPU

BLUETOOTH LED (Blue)

On

Link

Activity (per packet)

Blink

Disabled in PLC

(200ms flash)

No Link

Off

Blink

Pairing Mode

(500ms flash)

Blink

ERROR LED (RED)

On

Self Diagnostic

Error

Self Diagnostic

Warning

No Error

Off

Blink

WLAN LED (Green)

On

Link

Activity

No Link

Off

Blink

POWER LED (Green)

On Power Good

USB Low

Power Mode

Power Failure

Off

Blink

RUN LED (Green)

On CPU Run Mode

Initializing

Analog Module

CPU Program

Mode

Off

Blink

LED Status Indicators

Connecting via USB

To connect the CLICK PLUS CPU to a PC, use a USB A

to USB micro-B cable, such as the AutomationDirect

USB-CBL-AMICB6 cable.

1.

Connect the cable between the CPU micro-B port and an

available USB port on your PC.

USB Cable

ADC Part #

USB-CBL-AMICB6

PC with

USB A Port

USB B

Port

CLICK Plus

PLC

2.

Once connected open the Software and select the PLC Menu

and Connect.

3.

In the Connect to PLC Window, select USB for Port Type.

4.

For Com Port No., select the COMX (CLICK PLUS).

LOAD A PROJECT

The CLICK PLUS CPU is now ready to continue

configuration using the CLICK software and load a project.