Page 2

DURA

pulse

GS20 AC Drive Quick-Start Guide – 1st Ed, Rev C 03/03/2022

DURA

pulse

GS20 AC Drive Quick-Start Guide

GS20_QSP 1st Edition, Rev C 03/03/2022

P02.00

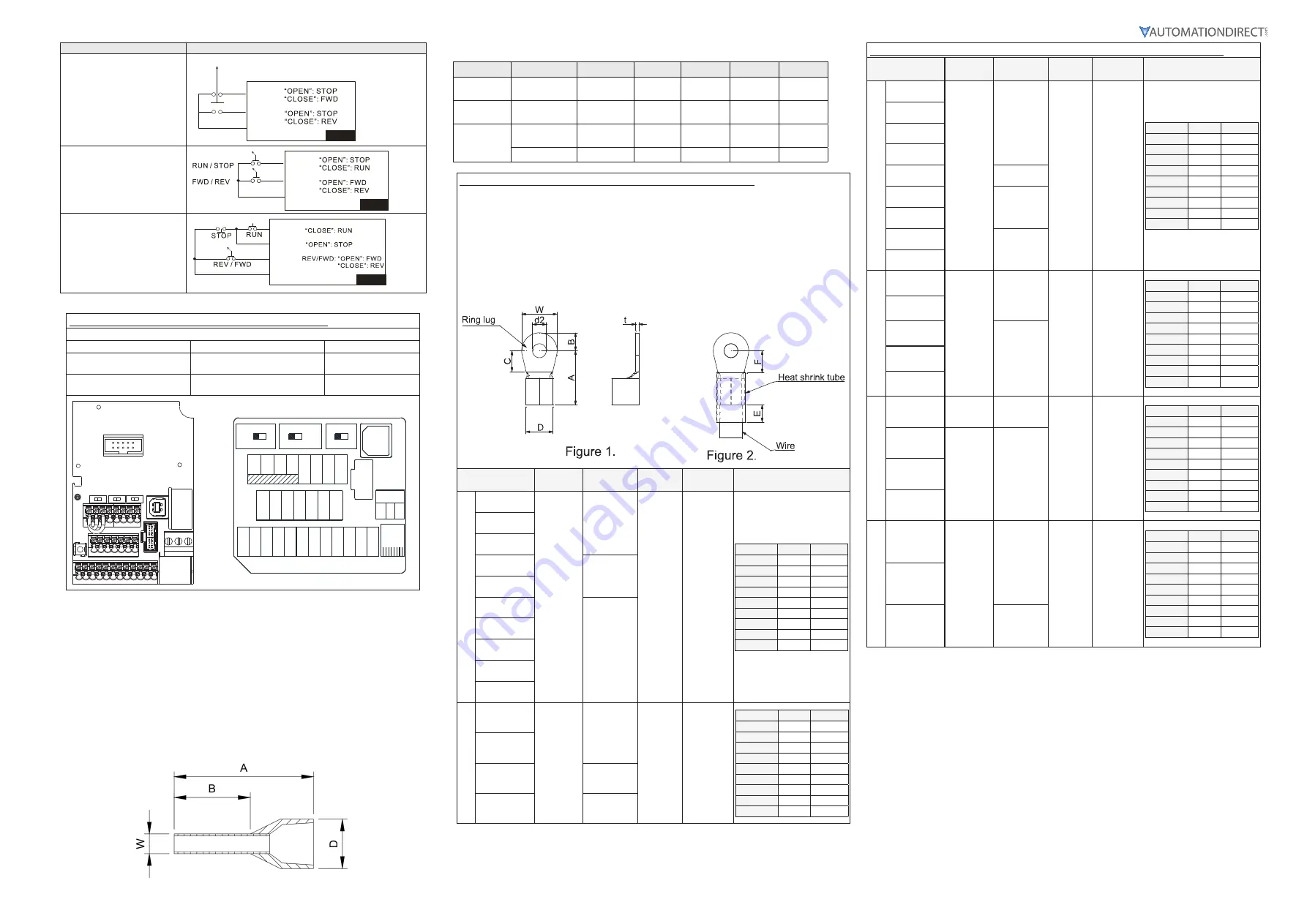

External Terminal Control Circuits

Setting value: 1

Two-wire operation control

FWD / STOP

REV / STOP

FWD/DI1

REV/DI2

DCM

GS20(X)

REV

RUN

FWD

RUN

STOP

Setting value: 2

Two-wire operation control

RUN / STOP

FWD / REV

FWD/DI1

REV/DI2

DCM

GS20(X)

Setting value: 3

Three-wire operation control

FWD/DI1

REV/DI2

DCM

GS20(X)

DI3

Specifications for Wiring Terminals – Control Circuit

GS20-xxxx All Models; All Frame Sizes

Terminal

Wire Gauge

Torque

Control

24–18 AWG

[0.21–0.82 mm

2

]

n/a (spring terminals)

Relay

24–16 AWG

[0.21–1.31 mm

2

]

5kg·cm

[4.3 lb·in]

FWD

AI2

A

O1

D

O

1

D

O

2

DC

M

DC

M

DO

+10

V

REV

DI3

DI4

DI5

+2

4V

+2

4V

STO1

STO2

SC

M

SG

+

SG

-

DOC

+2

4V

SLOT

1

24

P

SGND

32637012

DATAMATRIX

RELAY

R

1O

R

1C R1

AI2

AO1

0-20mA 4-

20mA

0-

10

V

0-

10

V

USB

Safety function

RS485

Port

DI6

DI7

PN

P

N

PN

A

C

M

AI1

0-20mA 4-

20mA

Wiring Precautions

1) The factory default condition is +24 V/ S1/ S2 shorted by jumper, as shown in the block 1 of the figure above.

Refer to the wiring chapter of the User Manual for more details.

2) The +24 V power supply for safety function is only for STO use and cannot be used for other purposes.

3) The RELAY terminal uses the PCB terminal block:

• Tighten the wiring with a 3.5 mm width and 0.6 mm thickness slotted screwdriver.

• The ideal length of stripped wire at the connection side is 6–7 mm.

• When wiring bare wires, make sure they are perfectly arranged to go through the wiring holes.

4) The control circuit terminal uses a spring clamp terminal block:

• Tighten the wiring with a 2.5 mm width and 0.4 mm thickness slotted screwdriver.

• The ideal length of stripped wire at the connection side is 9 mm.

Recommended models or dimensions for ferrule terminals

Wire Gauge

Manufacturer

Model Name

A (MAX)

B (MAX)

D (MAX)

W (MAX)

0.25 mm2

[24 AWG]

PHOENIX

CONTACT

AI 0,25- 8 YE

12.5

8

2.6

1.1

0.34 mm2

[22 AWG]

PHOENIX

CONTACT

AI 0,34- 8 TQ

12.5

8

3.3

1.3

0.5 mm2

[20 AWG]

PHOENIX

CONTACT

AI 0,5 - 8 WH

14

8

3.5

1.4

Z+F

V30AE000006

14

8

2.6

1.15

Specifications for Wiring Terminals – Main-Circuit Terminals

Notes:

• If you install at Ta 45°C above environment, please use copper wire with a 600V voltage rating and

temperature resistance of 90°C or higher.

• For UL compliant installation, you must:

1) Use 75°C temperature resistant copper wire or better. Do not reduce wire gauge when using higher

temperature wire.

2) Use the specific ring lug part listed in the table below.

3) Use crimp tool KST2000D-1322 or IZUMI 5N18 for 22

–

8 AWG wire, or

IZUMI 9H-60 for 6

–

4 AWG wire.

Drive Models

Max Wire

Gauge

Min Wire

Gauge

Screw

Size

Torque

(±10%)

Ring Lug Dimensions (mm)

Fr

ame A

GS21-10P2

14AWG

[2.5 mm

2

]

14AWG

[2.5 mm

2

]

M3.5

9 kg-cm

[7,8 lb-in.]

[0.88 N

·

m]

Dimension

Value

Min/Max

A

9.8

Max

B

3.2

Max

C

4.8

Min

D

4.1

Max

d2

3.7

Min

E

13.0

Min

F

4.2

Min

W

6.6

Max

t

0.8

Max

GS21-10P5

GS21-20P5

GS23-21P0

16AWG

[1.5 mm

2

]

GS21-20P2

GS23-20P2

18AWG

[0.75 mm

2

]

GS23-20P5

GS23-40P5

GS23-41P0

GS23-51P0

Fr

ame B

GS21-21P0

12AWG

[4 mm

2

]

12AWG

[4 mm

2

]

M4

15 kg-cm

[13,0 lb-in.]

[1.47 N

·

m]

Dimension

Value

Min/Max

A

12.1

Max

B

3.6

Max

C

6.1

Min

D

5.6

Max

d2

4.3

Min

E

13.0

Min

F

4.5

Min

W

7.2

Max

t

1

Max

GS23-22P0

GS23-42P0

14AWG

[2.5 mm

2

]

GS23-52P0

18AWG

[0.75 mm

2

]

Specifications for Wiring Terminals – Main-Circuit Terminals (continued)

Drive Models

Max Wire

Gauge

Min Wire

Gauge

Screw

Size

Torque

(±10%)

Ring Lug Dimensions (mm)

Fr

ame C

GS21-11P0

8AWG

[10 mm

2

]

8AWG

[10 mm

2

]

M4

20 kg-cm

[17,4 lb-in.]

[1.96 N

·

m]

Dimension

Value

Min/Max

A

17.8

Max

B

5.0

Max

C

6.1

Min

D

7.2

Max

d2

4.3

Min

E

13.0

Min

F

5.5

Min

W

10.5

Max

t

1.2

Max

GS21-22P0

GS21-23P0

GS23-25P0

GS23-23P0

10AWG

[6 mm

2

]

GS23-45P0

12AWG

[4 mm

2

]

GS23-55P0

GS23-43P0

14AWG

[2.5 mm

2

]

GS23-53P0

Fr

ame D

GS23-27P5

8AWG

[10 mm

2

]

8AWG

[10 mm

2

]

M4

20 kg-cm

[17,4 lb-in.]

[1.96 N

·

m]

Dimension

Value

Min/Max

A

17.8

Max

B

5.0

Max

C

6.1

Min

D

7.2

Max

d2

4.3

Min

E

13.0

Min

F

5.5

Min

W

10.5

Max

t

1.2

Max

GS23-4010

GS23-47P5

10AWG

[6 mm

2

]

GS23-57P5

GS23-5010

Fr

ame E

GS23-2015

4AWG

[25 mm

2

]

4AWG

[25 mm

2

]

M5

25 kg-cm

[21,7 lb-in.]

[2.45 N

·

m]

Dimension

Value

Min/Max

A

27.1

Max

B

6.1

Max

C

10.5

Min

D

11.5

Max

d2

5.3

Min

E

13.0

Min

F

6.5

Min

W

12.6

Max

t

1.7

Max

GS23-2010

6AWG

[16 mm

2

]

6AWG

[16 mm

2

]

GS23-4015

GS23-4020

Fr

ame F

GS23-2020

2AWG

[35 mm

2

]

2AWG

[35 mm

2

]

M6

40 kg-cm

[34,7 lb-in.]

[3.92 N

·

m]

Dimension

Value

Min/Max

A

35.0

Max

B

9.0

Max

C

13.3

Min

D

14.0

Max

d2

6.2

Min

E

13.0

Min

F

10

Min

W

19.5

Max

t

1.8

Max

GS23-4030

GS23-4025

4AWG

[25 mm

2

]