DUAL INDICATOR TEMPERATURE CONTROLLER

TCN4 SERIES

M A N U A L

Thank you very much for selecting Autonics products.

For your safety, please read the following before using.

1. In case of using this unit with machinery (Ex: nuclear power control, medical equipment, ship,

vehicle, train, airplane, combustion apparatus, safety device, crime/disaster prevention

equipment, etc) which may cause damages to human life or property, it is required to install

fail-safe device.

It may cause a fire, human injury or damage to property.

2. Install the unit on a panel.

It may cause electric shock.

3. Do not connect, inspect or repair this unit when power is on.

It may cause electric shock.

4. Wire properly after checking terminal number.

It may cause a fire.

5. Do not disassemble the case. Please contact us if it is required.

It may cause electric shock or a fire.

Caution for your safety

Ordering information

Specifi cation

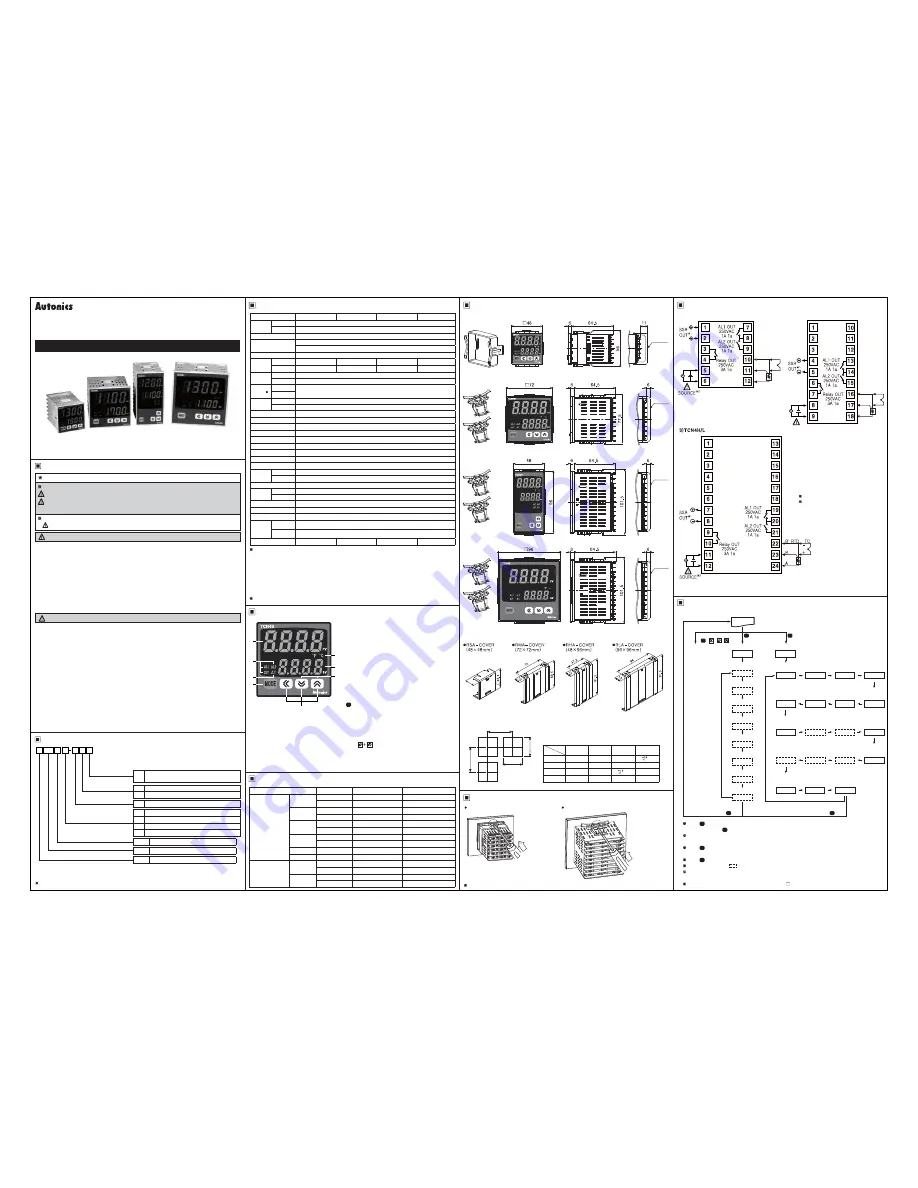

Dimensions

Connections

1)TCN4S

1)TCN4S

2)TCN4M

Parts description

Input sensor and temperature range

Warning

Please keep these instructions and review them before using this unit.

Please observe the cautions that follow;

Serious injury may result if instructions are not followed.

The following is an explanation of the symbols used in the operation manual.

Caution: Injury or danger may occur under special conditions.

1. This unit shall not be used outdoors.

It may shorten the life cycle of the product or cause electric shock.

2. When connect wire, AWG 20(0.50mm

2

) should be used and screw bolt on terminal block with

0.74N.m to 0.90N.m strength.

It may cause a malfunction or fire due to contact failure.

3. Please observe the rated specifications.

It may shorten the life cycle of the product and cause a fire.

4. Do not use beyond of the rated switching capacity of relay contact.

It may cause insulation failure, contact melt, contact failure, relay broken and fire etc.

5. In cleaning unit, do not use water or organic solvent. And use dry cloth.

It may cause electric shock or a fire.

6. Do not use this unit in place where there are flammable or explosive gas, humidity, direct ray

of the light, radiant heat, vibration and impact etc.

It may cause a fire or an explosion.

7. Do not inflow dust or wire dregs into the unit.

It may cause a fire or a malfunction.

8. Please wire properly after checking the terminal polarity when connecting temperature sensor.

It may cause a fire or an explosion.

9. In order to install the units with reinforced insulation, use the power supply unit which basic

insulation level is ensured.

Caution

The above specifications are subject to change without notice.

T

4 S

2 4 R

CN

R

Relay contact SSRP output (AC power)

Relay contact SSR output (AC/DC power)

2

24VAC 50/60Hz, 24-48VDC

4

100-240VAC 50/60Hz

2

Alarm2 output

S

DIN W48 X H48mm

M

DIN W72 X H72mm

H

DIN W48 X H96mm

L

DIN W96 X H96mm

4

4Digit(9999)

CN

Dual display type, set by touch switch

T

Temperature controller

Item

Setting type

Digit

Size

Sub output

Power supply

Control output

Series

TCN4S

TCN4M

TCN4H

TCN4L

Power

supply

AC Power

100-240VAC 50/60Hz

AC/DC Power

24VAC 50/60Hz, 24-48VDC

Allowable voltage range

90 to 110% of rated voltage

Power consumption

Max. 5VA(100-240VAC 50/60Hz, 24VAC 50/60Hz)

Max. 3W(24-48VDC)

Display method

7 Segment LED(PV: Red, SV: Green)

Character

size

PV(WXH) 7.0 X 15.0mm

9.5 X 20.0mm

7.0 X 14.6mm

11.0 X 22.0mm

SV(WXH) 5.0 X 9.5mm

7.5 X 15.0mm

6.0 X 12.0mm

7.0 X 14.0mm

Input

type

RTD

DIN Pt100

Ω

, Cu50

Ω

(Allowable line resistance max.5

Ω

per a wire)

TC

K(CA), J(IC), L(IC), T(CC), R(PR), S(PR)

Display

accuracy

1

RTD

Based on room temperature (23ºC ± 5ºC): (PV ± 0.5% or ±1ºC higher one) rdg ± 1 Digit

In case of out of room temperature range: (PV ± 0.5% or ±2ºC higher one) rdg ± 1Digit

TC

Control

output

Relay

250VAC 3A 1a

SSR

12VDC±2V 20mA Max.

Alarm output

AL1, AL2 Relay: 250VAC 1A 1a

Control method

ON/OFF control, P, PI, PD, PID control

Hysteresis

1 to 100ºC/0.1 to 50.0ºC

Proportional band(P) 0.1 to 999.9ºC

Integral time(I)

0 to 9999 sec.

Derivative time(D)

0 to 9999 sec.

Control period(T)

0.5 to 120.0 sec.

Manual reset

0.0 to 100.0%

Sampling period

100ms

Dielectric

strength

AC power

2000VAC 50/60Hz 1min.(Between input terminal and power terminal)

AC/DC power

1000VAC 50/60Hz 1min.(Between input terminal and power terminal)

Vibration

0.75mm amplitude at frequency of 5 to 55Hz in each X, Y, Z directions for 2 hours

Relay life

cycle

Control output Mechanical: Min. 5,000,000 operations, Electrical: Min. 200,000 operations (250VAC 3A resistive load)

Alarm output

Mechanical: Min. 5,000,000 operations, Electrical: Min. 300,000 operations (250VAC 1A resistive load)

Insulation resistance Min. 100M

Ω

(at 500VDC megger)

Noise immunity

Square-wave noise by noise simulator(pulse width 1

㎲

) ±2KV R-phase and S-phase

Memory retention

Approx. 10 years (When using non-volatile semiconductor memory type)

Environ

-ment

Ambient

Temperature

-10 to 50ºC, Storage: -20 to 60ºC

Ambient

humidity

35 to 85%RH, Storage: 35 to 85%RH

Unit weight

Approx. 100g

Approx. 133g

Approx. 124g

Approx. 179g

1: For display accuracy

- In case of room temperature (23ºC ± 5ºC)

Below 200ºC of thermocouple R, S is PV ± 0.5% or ±3ºC higher one ± 1 digit

Over 200ºC of thermocouple R, S is PV ± 0.5% or ±2ºC higher one ± 1 digit

Termocouple L (IC), RTD CU50

Ω

is PV ± 0.5% or ±2ºC higher one ± 1 digit

- In case of out of room temperature range

Below 200ºC of thermocouple R, S is PV ± 1.0% or ±6ºC higher one ± 1 digit

Over 200ºC of thermocouple R, S is PV ± 0.5% or ±5ºC higher one ± 1 digit

RTD CU50

Ω

is PV ± 0.5% or ±3ºC higher one ± 1 digit

Environment resistance is rated at no freezing or condensation.

1

3

4

5

6

2

7

8

1. Present temperature (PV) display (Red)

1) RUN mode: Present temperature (PV) display

2) Parameter setting mode: Parameter display

2. Set temperature (SV) display (Green)

1) RUN mode: Set temperature (SV) display

2) Parameter setting mode: Parameter setting value display

3. Control/Alarm output display lamp

1) AL1/AL2: When AL1, AL2 alarm output ON, this lamp

turns ON.

2) OUT: When control output ON, this lamp turns ON.

During SSRP control output type in CYCLE/PHASE

control, this lamp turns ON when MV is over 3.0%.

4. Auto tuning lamp

AT lamp flashes by every 1 sec during operating auto tuning.

5.

MODE

key

Used when entering into parameter setting group, returning

to RUN mode, moving parameter, and saving setting values.

6. Adjustment

Used when entering into set value change mode, digit

moving and digit up/down.

7. Digital input key

Press

keys for 3 sec. to operate the set function

(RUN/STOP, alarm output reset, auto tuning) in digital input

key [

DI-T

].

8. Temperature unit (

ºC

/

℉

) indicator

It shows current temperature unit.

Input sensor

Display

Temperature range(ºC)

Temperature range(

℉

)

Thermorcouple

K(CA)

KCaH

-50 to 1200

-58 to 2192

KCaL

-50.0 to 999.9

-58.0 to 999.9

J(IC)

JIcH

-30 to 800

-22 to 1472

JIcL

-30.0 to 800.0

-22.0 to 999.9

L(IC)

LIcH

-40 to 800

-40 to 1472

LIcL

-40.0 to 800.0

-40 to 999.9

T(CC)

TCcH

-50 to 400

-58 to 752

TCcL

-50.0 to 400.0

-58.0 to 752.0

R(PR)

RPR

0 to 1700

32 to 3092

S(PR)

SPR

0 to 1700

32 to 3092

RTD

DPt100

Ω

DPtH

-100 to 400

-148 to 752

DPtL

-100.0 to 400.0

-148.0 to 752.0

CU50

Ω

CUsH

-50 to 200

-58 to 392

CUsL

-50.0 to 200.0

-58.0 to 392.0

2)TCN4M

5)Terminal cover(Sold separately)

6)Panel cut-out

4)TCN4L

D

A

B

C

A

B

C

D

TCN4S

Min. 65

Min. 65

45

45

TCN4M

Min. 90

Min. 90

68

68

TCN4H

Min. 65

Min. 115

45

92

TCN4L

Min. 115

Min. 115

92

92

+0.6

-0

+0.7

-0

+0.7

-0

+0.8

-0

+0.8

-0

+0.8

-0

Model

Unit

[Unit: mm]

B' RTD TC

-

+

B

A

B' RTD TC

-

+

B

A

SOURCE

※2

1: 12VDC±2V 20mA Max.

2: AC power: 100-240VAC 5VA 50/60Hz

AC/DC power: 24VAC 5VA 50/60Hz

24-48VDC 3W

Flow chart for setting group

Press

MODE

key over 3 sec in any setting group, it saves the set value and returns to RUN mode.

(Exception: Press

MODE

key once in SV setting group, it returns to RUN mode).

If no key entered for 30 sec., it returns to RUN mode automatically and the set value of parameter is

not be saved.

Press

MODE

key again within 1 sec. after returning to RUN mode, it advances of the

fi

rst parameter of

previous setting group.

Press

MODE

key to move next parameter.

Parameter marked in

might not be displayed depending on other parameter settings.

Set parameter as 'Parameter 2group

→

Parameter 1group

→

Setting group of set value' order

considering parameter relation of each setting group.

1: It is not displayed for AC/DC power model (TCN4 -22R).

Run mode

PAR1

IN-T

MAvF

PAR2

SV setting

Parameter 1group

Parameter 2group

AL1

AL1 alarm termerature

AL2 alarm termerature

Input

sensor

UNIT

Temperature

unit

IN-B

Input

correction

Input

digital

fi

lter

L-SV

SV low-limit

value

H-SV

SV high-

limit value

O-FT

Control output

operation

C-MD

Control type

OUT

Control output

type

SSrM

SSRP output

method

※

1

T

Control

cycle

AL-1

AL1 alarm

operation mode

AL-2

AL2 alarm

operation mode

AHYS

Alarm output

hysteresis

LBaT

LBA

monitoring time

LBaB

LBA detection

band

DI-K

Digital input

key

ErMV

Control output MV in case

of input break error

LOC

Lock setting

AL2

AT

Auto tunung

P

Proportional band

I

Integral time

D

Derivative time

REST

Manual reset

HYS

Hysteresis

MODE

MODE

2sec.

Please any key among

MODE

, , ,

4sec.

1. All Parameter

Installation

TCN4S(48X48mm) series

Other series

Insert product into a panel, fasten bracket by pushing with tools as shown above.

3)TCN4H

+

-

+

-

+

-

Warning

Caution

Product may be damaged, or injury may result if instructions are not

followed.

Terminal

cover

Terminal

cover

Terminal

cover

Terminal

cover

MODE

3sec.

MODE

3sec.

22