2D-2

Special considerations for the AutoPilot

Combina-

tion

Manifold

Under normal operation, a small amount of gas is introduced

into the pool system by the injector. Plumb the Manifold so that

these bubbles do not interfere with the operation of pool equip-

ment. For example:

1.

Install the manifold after any Pressure Pool Cleaners (such

as a Polaris 360).

2.

Install the manifold after any Tablet/Erosion Feeders that

could collect gas bubbles.

2D-3

. Water Check Valve:

If the pool equipment is mounted

above the water line, a check valve must be installed between

the pump outlet and the Injector Manifold. This will prevent the

pump from draining and losing its prime (when not in use).

2D-4

. Pressure Test:

If a pressure test is required, it should be performed prior to

connecting the Ozone Gas Line. A 3/4” pipe cap is provided

for the pressure test.

2D-5.

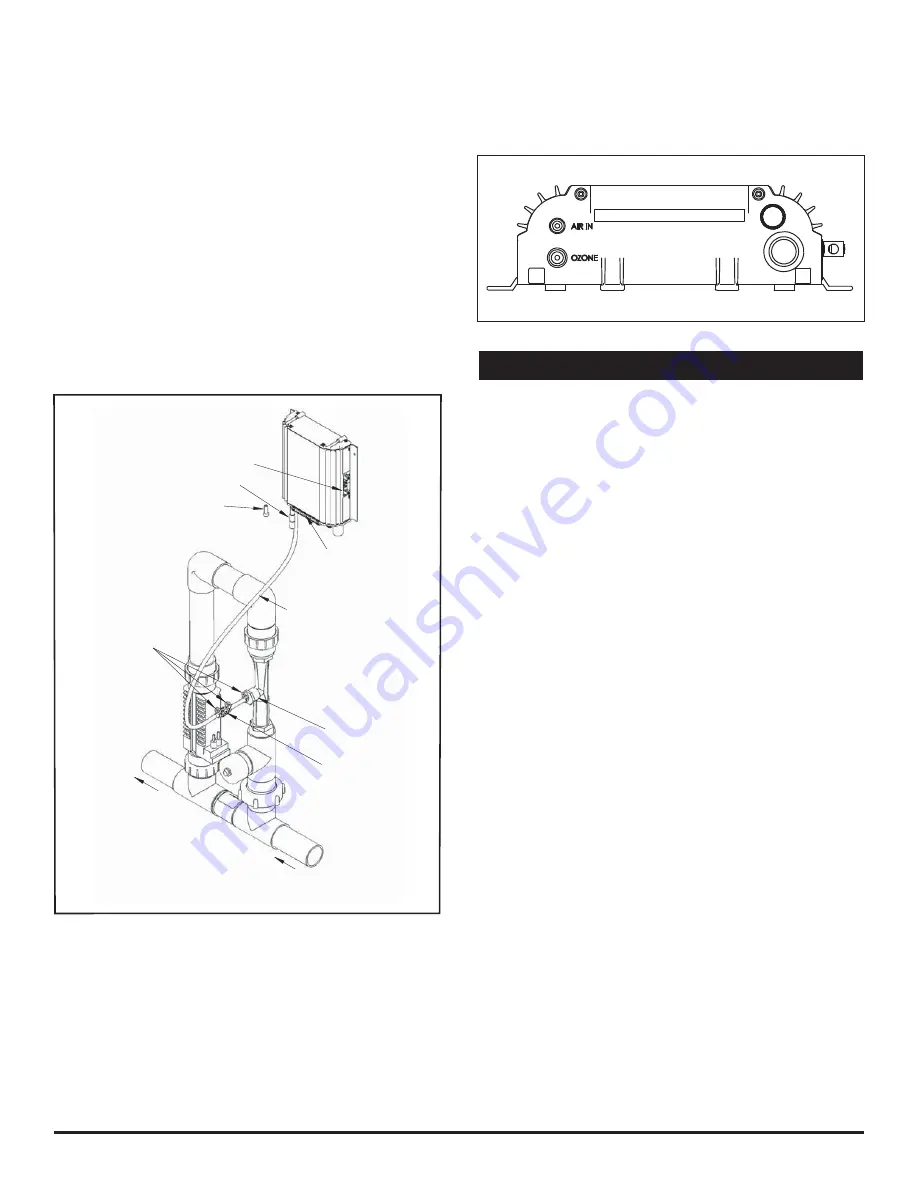

Ozone Gas Line - refer to Figure 2.

1.

Install Tube Adapter on injector. Use thread sealant if

needed. (Do not use thread tape.)

2.

Connect the shorter end of the Ozone Check Valve and

Tube Assembly with the check valve installed onto the

Tube Adapter.

3.

Cut off the excess tubing from the longer end so that the

line from the injector to the CoPilot is as straight and free

from dips and loops as possible.

4. Install Clamps on the Tube Adaptor and on both ends of

Check Valve.

Equipment

Ozone Check Valve

From Pool

Flowmeter

Tube Adapter

and Tube Assembly

to Pool

Return

Lug(s)

Bonding

Indicators

Ozone Power

Flow Control Assembly

(Install after checking flow)

(Preinstalled)

Check Valve

Clamps

3

Figure 2

Installation Diagram

5.

The base of the CoPilot has two tube connections. Con-

nect the longer end of the ozone supply tubing to the

port marked "OZONE" (see Bottom View - Figure 3).

NOTE: Connecting the Ozone Line to the incorrect port

will cause damage to the ozone generator.

SECTION 3

Operation

Operation

3A General

To achieve optimal performance from the CoPilot system, the

pool must be as clean as possible to start with. Refer to the

“Pool Water Preparation” section of your Pool Pilot manual.

3B Initial System Start-Up

Upon completing all of the system connections and cleaning

the pool, you are ready to start the CoPilot.

1.

Check electrical connections.

2

. Check for proper voltage.

3.

Turn on pool circulation system.

3C Normal Operation

1.

Ozone Power

Indicator Lights: When the pool’s circulation

system starts, the green LED indicator(s) on the front of

the CoPilot will illuminate. The COP-A and COP-B should

show 1 and 2 indicators, respectively.

2.

Gas Flow: Connect the Flowmeter provided to the “AIR IN”

port on the base of the CoPilot (see Figure 3). Under worst-

case system conditions the Flowmeter Ball should indicate

at least a small amount of air fl ow. If not, adjust system

valves as required to reduce back pressure and/or increase

fl ow through the manifold. Under nominal conditions, the

Ball should fl oat above the middle of the fl owmeter. It is ok

if the Ball is all the way at the top if it is not stuck. Tap the

Flowmeter to verify that the Ball is not stuck.

If you experience complications see TROUBLESHOOTING

Section 4D.

3D Flow Control Assembly

Once proper suction is established, remove the Flowmeter

and install the Flow Control Assembly on the “AIR IN” port of

the CoPilot. The Flow Control Assembly must remain attached

to the CoPilot, except when temporarily removed to verify fl ow

with the Flowmeter

3E System Shut-Down

The following sequence of steps must be followed for servicing

or for storage.

CoPilot Corona Discharge Ozone Generators

Figure 3

CoPilot Connections