7

Additional air duct components can be added to the heater for distributing hot air. Each

of the components has its own conductivity factor and it reduces total flow rate of hot air.

In order for you to be sure that the option you have selected for the installation of air ducts,

is acceptable and will not result in a massive flow rate reduction of hot air or overheating

of the heater, you need to calculate the total conductivity of complete air duct system (see

example below).

Components connected to heater should

not exceed coefficient of conductivity of

the heater (see Table 1). Otherwise, the

temperature of heated air can increase to

unacceptably high level, heat will be

distributed unevenly, and it could result in

overheating that could damage the heater.

Table 1 – Maximum coefficient of conductivity

of the heater

Heater

Size of

duct

Coef

PLANAR 2D-12/24

ø60 mm 50

PLANAR 44D-12/24 ø75 mm 30

PLANAR 44D-12/24 ø90 mm 100

If the sum of individual conductivity coefficients exceeds maximum coefficient of

conductivity of the heater (see Table 1), it can be reduced by increasing the diameter of the

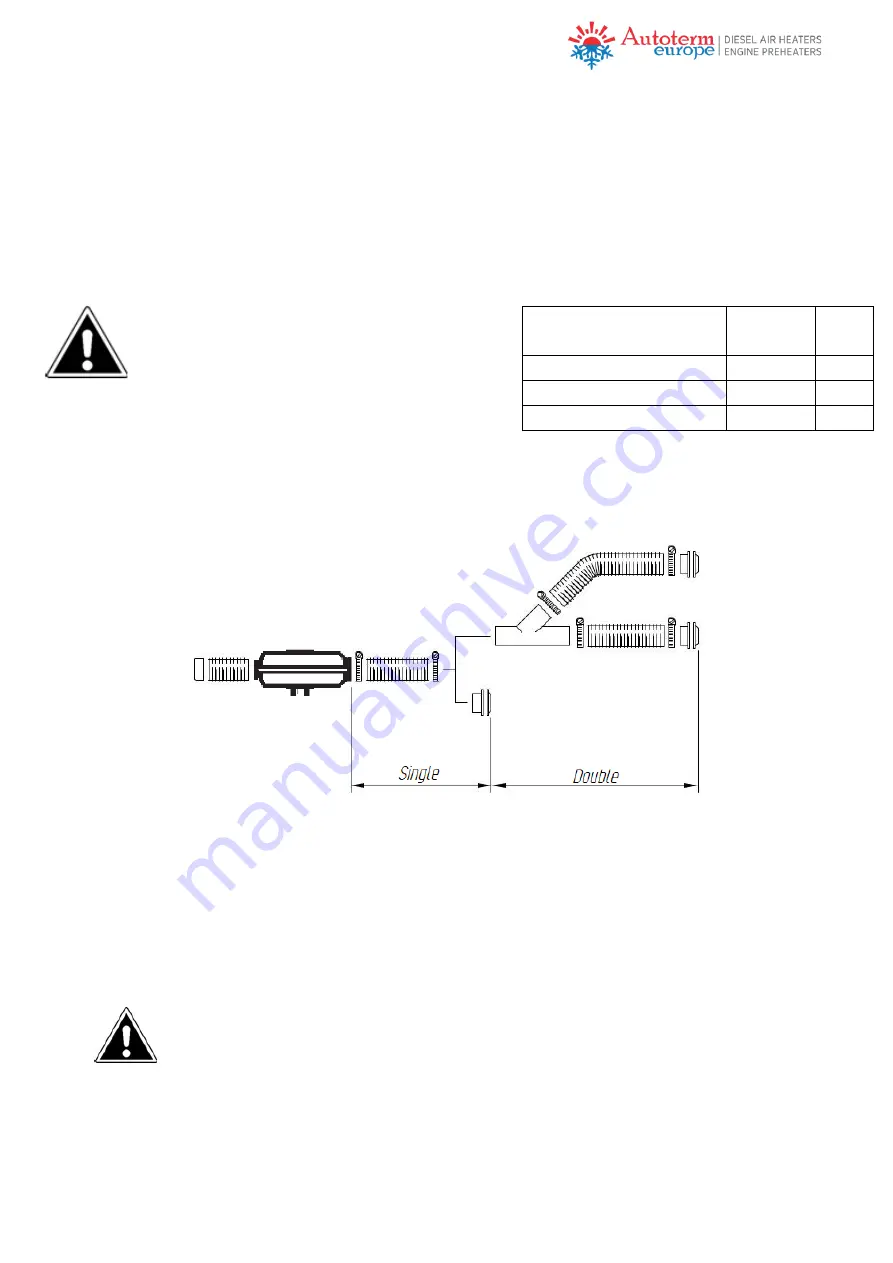

air ducts or installing double channel system instead of a single channel system (Fig.4).

Fig. 4 – Single and double channel air ducts

Single channel system – Only one channel of air ducts connect at heaters air input

(only for PLANAR 2D) and output.

Double channel system – after the heater, the hot air duct splits into two channels. Up

until the point where air duct splits in two channels, it counts as a single channel system,

therefore single channel conductivity coefficients are used for calculations. After that point,

it becomes a double channel system so double channel conductivity coefficients must be

used for calculations.

When using double channel air ducts, at least one channel should

always be open.

See Fig.5 for example of installed air duct. Total conductivity coefficient can be seen

in Table 2. The sum of the individual conductivity coefficients is 44. It does not exceed the

coefficient of conductivity of the heater = 50. In this case, the installation is allowed.

Conductivity coefficients for components of single and double channel systems can

be seen in Table 3.