All rights reserved. No part of this manual may be used in any form or by any means without written permission of the copyright owner.

11

из

12

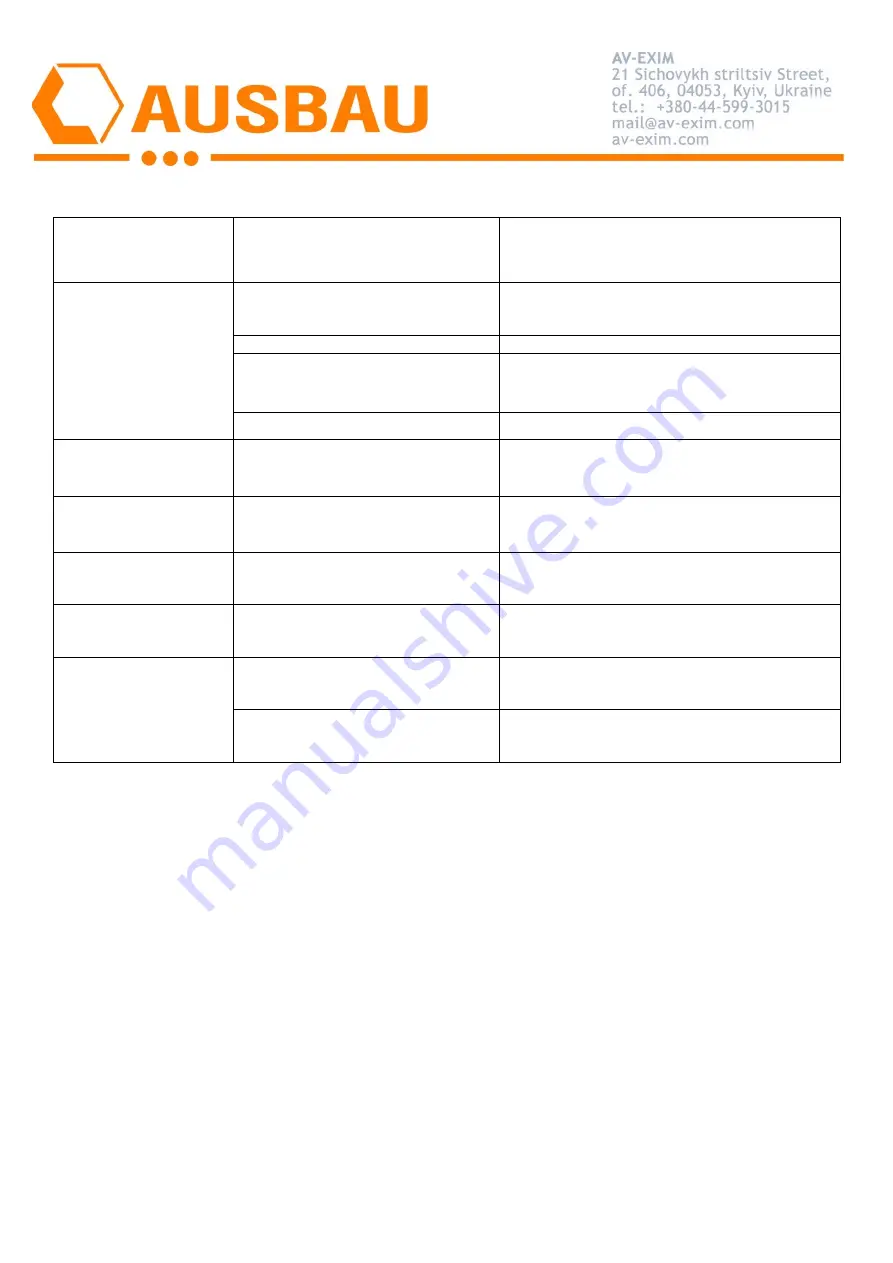

13. Typical faults and solutions

Name of the trouble.

External signs and

additional signs

Possible reason

Method of elimination

The ramp does not rise

Hydraulic pump leaks

Check the location valve, clean it if there is any

dirt on the surface or inside

There is a load on the ramp

Remove the load

The system is vented due to a

small amount of oil

Fill the tank with oil, open the plug on the pump,

bleed out all the air, close the plug

Opened valve on the pump

Close ramp lift valve

Climbing speed is too

slow

Fluid leaks from hoses or cylinders

Replace hoses or cylinders

Ramp does not rise to

the required height

Low oil level in the tank

Refill the oil according to the supplier's

recommendations

The ramp does not go

down

Descent valve is out of service

Check the location valve, clean it if there is any

dirt on the surface

The wheels in the

ramp are driving away

The ramp carried the load without

support on transport

Not a warranty case. Replace wheel bearing

and/or axle with hubs/wheels. Contact your

supplier

Ramp falls down

Hydraulic pump leaks

Check the location valve, clean If there is any dirt

on the surface

Tank leakage

Weld (or close in other

wayotherwise close) the leaking

hole

Please, don’t doubt to call/email supplier. We are always open to help you:

Tel: +38 044 599 30 15

+49 302 555 98 68

+48 22 390 64 43

+421 23 333 10 75

+40 37 170 02 36

+420 23 409 21 33

+370 5 214 10 33

+36 1 800 16 67

+31 970 102 808 98

E-mail: mail@av-exim.com