All rights reserved. No part of this manual may be used in any form or by any means without written permission of the copyright owner.

5

из

12

The middle and upper parts of the ramp have decks that provide maximum grip of the forklift wheels on the surface

and free drainage of water.

The connection lip is made of thick steel sheet.

In the central part of the product there is a hydraulic group that provides raising and lowering of the ramp. The

hydraulic group consists of a hydraulic station (includes a manual pump, oil flow valve and oil tank) and two hydraulic

cylinders (single-acting with return to initial position under the ramp's own weight).

To move the ramp in its lower part, between the lifting bridges of the entrance or on the side, there is a tow pole for

one "fork" forklift.

In the upper horizontal part of the ramp there are chains with carabiners (hooks) for fixation of the ramp with the

car body. In the middle of the ramp, on both sides there are wheel chocks for fixing the ramp wheels during

loading/unloading.

* The manufacturer reserves its right to make changes in the design of the product without prior notice.

If you purchased a ramp with the 2SL3SW and/or EHP options, request an addition

to this manual from your supplier. Do not operate the ramp without reading the

required addendum.

Adjustable 2SL supporting legs, serve as a safety feature in case the truck suddenly pulls

away and the chain breaks. When driving the forklift over the ramp, it is strictly forbidden to

rest the ramp on the supporting legs.

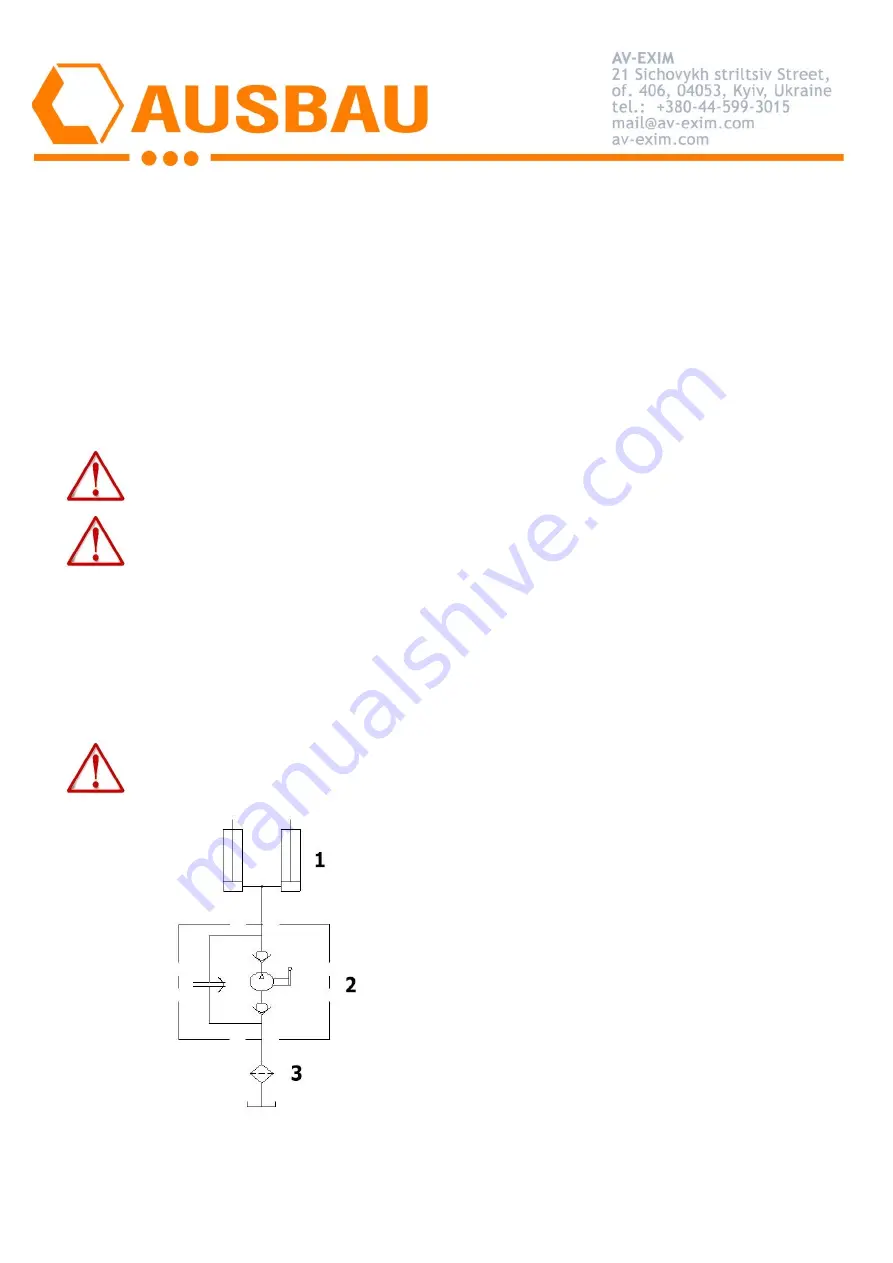

5. Description of the hydraulic station

A manual hydraulic pump transfers oil under pressure from the oil tank to the hydraulic cylinders, in this way the

"body" of the ramp is raised. When the ramp is lowered (not faster than 5-8 mm/sec), the hydraulic oil flows to the tank

through a distribution valve under the control of a speed limiting valve and a flow control valve.

The oil level should be no less than 1/2 and no more than 3/4 of the oil tank volume when the ramp is fully lowered.

The oil level should be checked before operation and refilled if necessary.

The hydraulic group (hydraulic cylinders, high-pressure hoses, triple adaptors,

connectors and pump) are consumables and are not included in the warranty list of materials

to be replaced under warranty.

1

–

Cylinders.

2

–

Pump.

3

–

Oil tank.

The information on the contour frame only explains the essence of the hydraulic principle.