All rights reserved. No part of this manual may be used in any form or by any means without written permission of the copyright owner.

10

из

12

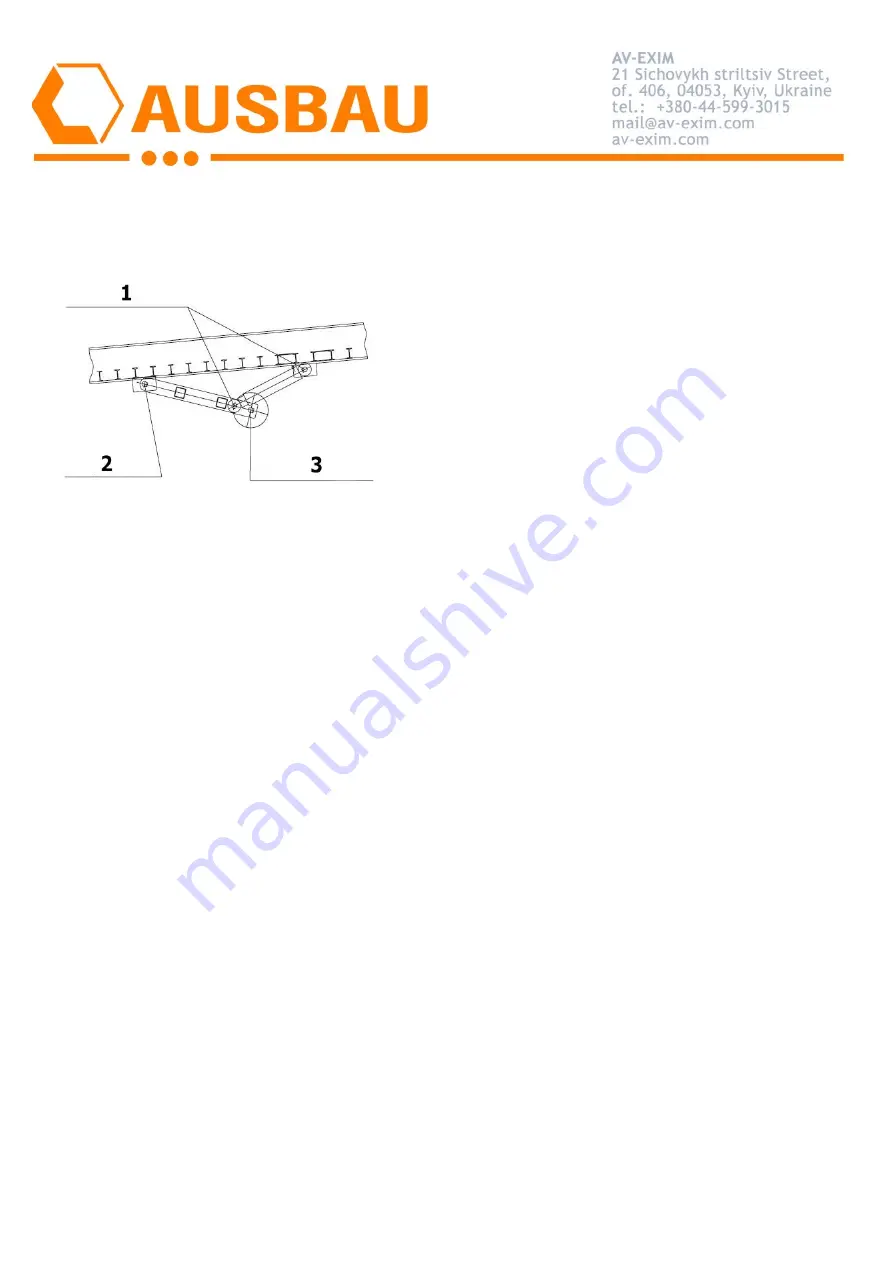

Thick Grease Points:

Thick grease points (Lithol-24 or equivalent) are shown below and should be checked at least every 6 months. All

grease points should be wiped down periodically with kerosene(or equivalent) to remove dirt and fresh grease should

be applied.

1

–

Hydraulic cylinder axles.

2

–

Lever axles.

3

–

Wheel Supports.

12. Maintenance

Monthly maintenance

1. During inspection check the condition of connections for wear and damage, the presence and condition of

lubricant in moving parts, if necessary, lubricate them. Moving parts of the ramp (bushings, axles, bearings) should be

checked at least once every 3 months. All lubrication points should be periodically wiped with kerosene(or equivalent)

to remove dirt and then a fresh grease should be applied (e.g. Lithol-24 or equivalent).

2. Check oil level and quality in the tank. Oil level - with the system full and the ramp in the down position, the oil

tank should be 3/4 full. If the oil is dirty, contaminated, or contains water, it must be replaced.

3. Check the operation of the hydraulic group for the presence/absence of leakage of hoses and sealing elements

of hydraulic cylinders. If necessary, replace the sealing elements of the hydraulic system.

Yearly maintenance

Do a complete oil change: drain the old oil, unscrew the valve and pull out the oil filter, which must be cleaned with

compressed air. Put it back in the oil tank, connect the tubes. Change the oil with new oil.

Painting for care

1. If the ramp is outdoors (not protected from rain or other precipitation), it should be painted every 6 months, thus

extending the life of the equipment.

2. If the ramp is covered with something that prevents contact with atmospheric precipitation, painting is required

every year.

3. If rust is evident, clean up the damaged areas and apply paint. Check with your supplier for the type of paint.

Other maintenance

If there is damage to the metal or welds, weld them up with welds.