2

Mount Description

The M-zeta Fast Reverse mount is a portable Dual Dec Azimuthal mount devoted to the Visual

Observation and to the imaging, in the capacity range up to 20 kg (44 lb).

The M-zeta design was developed on the basis of the following technical concepts:

•

Fast Reverse technology

•

Computer aided design (CAD)

•

High quality manufacturing with digital control 5 axes CNC machines (CNC + CAM)

•

Absolute quality materials: Anodized aluminium from milled mono-bloc, stainless steel

components and screws, brass components, techno-polymers

The M-Zeta motion transmission technology is based on pulley-tooth belt without play.

The M-Zeta is mainly designed for visual observing with high focal length catadioptric tubes

(such as SC-Maksutov, RC, SC cameras, Cassegrain, DK, etc) up to 10″ aperture and 20 kg (44

lb) weight, according to the tube length. It is possible to use the M-zeta with Newton optics (for

example 8" f4).

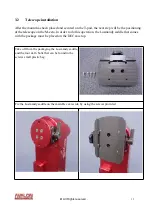

Another M-uno basic advantage is that it doesn't need neither counterweights, nor the bar. Its

declination axis can be quickly balanced like in an equatorial mount, while, for the RA axis, it is

possible to fix the arm on three possible positions and to make the fine balance using a very

small counterweight. The M-uno mount, as well as the LINEAR, is equipped with the super

tested, simple to use StarGo GoTo Control System.

The M-Zeta total weight is only 12.2 kg.

The use of pulleys and toothed belts has allowed to obtain several advantages: a really steady

motion without play (no backlash) and sudden peaks. These features are of particular relevance

especially during quick motors reverse, in this way it is possible to have the motion without

breaks to recover the plays: from here the mount name FAST REVERSE.

It is important to underline that in the gear-worm systems the motion transmission has only one

tangent point of contact, any errors on each of the two components will, sooner or later, result

into a tracking errors. On the contrary, in the pulley-toothed belt system, no direct contact

occurs between the pulley and the motion is transmitted by the belt engaging from 50% to 90%

of the girth surface. Consequently any error, eventually present, is averaged among the cogs,

moreover soft, greatly reducing the tracking error.

Another significant advantage of very low frictions is that the risks of motor slipping during

GOTO operation is virtually null. On the contrary, it is well known the difficulty to regulate the

coupling between gear and worm in the conventional mounts. If the coupling is tight the motors

can stuck with consequent loss of the position, if the coupling is too loose the plays increase.

Since there are no gears, there is no need of periodical lubrication of the internal components

and therefore the maintenance is extremely reduced and limited to the external cleaning.

©

All Rights reserved

-

7

Summary of Contents for M-zeta

Page 8: ...All Rights reserved 8...