Stove

Installation

(for qualified installers only)

9

© Travis Industries

100-01252_000

4101004

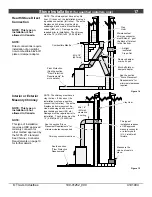

Top View -

Straight Installation

(i) Measure rear and side

clearances from the stove

top.

(j) Vent diameter varies

depending on brand and

model.

(k) Measure front

clearances from the stove

top.

24-1/2"

622mm

17-3/8" 441mm

5-3/4" 146mm

i

j

k

g

g

h

a

b

d

e

Figure 2

Top View -

Corner Installation

24-1/2"

622mm

17-3/8" 441mm

5-3/4" 146mm

c

f

i

j

k

g

g

h

Figure 3