42

Optional Equipment

© Travis Industries

93508061

4050526

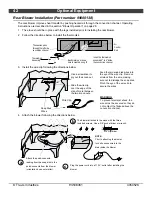

Rear Blower Installation (Part number 99000138)

The rear blower improves heat transfer by pushing heated air through the convection channel. Operating

instructions are described in the section "Blower Operation" on page 29.

1. The stove should be in place with the legs installed prior to installing the rear blower.

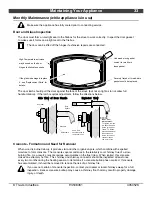

2. Follow the directions below to install the thermodisk.

Air

Control

Rod

These wires pass

through the left side

convection channel.

Bend metal up or down

here to create a snug fit

Thermodisk

Assembly

Insert the thermodisk

assembly 4" to 5" inside

the convection channel.

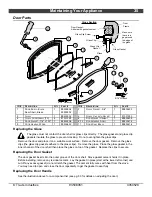

3. Install the wire clip following the directions below.

Slide the wire clip

over the edge of the

strip of metal between

the two knock-outs.

Feed the two snap disk wires into

the eye of the wire clip. Remove

all slack from the wire, making

sure not to dislodge the snap disk.

Pinch the eye of the wire clip to

secure the wires.

Wire Clip

Snap Disk

Wires

WARNING:

To prevent electrical shock, the

wires must be secured so they do

not contact the firebox above the

convection channel.

Use a screwdriver to

pry out the knock-out.

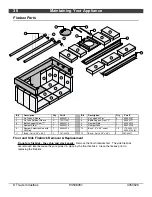

4. Attach the blower following the directions below.

NOTE:

Prior to attaching the blower,

tuck all excess wire into the

area inside the blower.

The blower attaches to the stove with the three

included screws. Use a 3/8” socket driver or wrench.

Plug the power cord into a 110 V. outlet after installing the

blower.

Attach the quick-connects

leading from the snap disk to the

quick-connects from the blower

(orientation does not matter).

3/8" Nutdriver

a

b

c

AA

AA