Avant 850

Service and maintenance

109

WARNING

Damaged or modified safety

structures do not protect in same

way as original ones.

In case the

ROPS safety frame or the FOPS

canopy of the machine gets

damaged, the machine must be

taken to Avant service for checking.

It is not allowed to repair the ROPS

and FOPS.

6.

Check tightness of bolts, nuts, and

fittings

Check tightness of bolts, nuts, and hydraulic fittings

regularly. Check visible bolts and hydraulic fittings

visually daily. Check bolts and fittings more

thoroughly as part of periodic maintenance. Do not

start the loader if any bolt, pivot pin, or hydraulic

fitting is loose, damaged, or missing.

Check pivot pins

Check the pivot pins and the tightness of the locking

screws that lock the pivot pins:

pins connecting the articulated frames

pins connecting the steering cylinder

pin connecting the boom to the front frame

all pins of the boom and its cylinders

If any pivot pin locking bolt is loose, apply thread

locker compound and tighten the bolt.

-

WARNING

Risk of dropping of load - Check

all pivot pins.

Check the tightness

of the locking screws of all pivot

pins. Also check the pivot pin

connecting the boom to the front

frame. If any of them is loose, use

thread locking compound and

tighten.

Check wheel nuts

Check tightening of the wheel nuts with a torque

wrench. Wheel nuts must be tightened to 225 - 275

Nm. The wheels and nuts settle in after first few

hours of use, check the tightness after 5 hours of

use.

Tighten wheel nuts after first 5

operating hours. Check tightness of

wheel nuts regularly.

Other bolts and nuts

Bolts and nuts on the loader are standard metric

system type. If replacement of bolt or nut is

necessary, replace both at the same time with ones

that are identical in size and grade.

Most bolts and nuts on the loader are metric grade

8.8. See the spare parts catalog for information

about bolts, nuts, and washers. Contact Avant

service if you are unsure of suitable fasteners.

Check the bolts connecting the rear frame

extension to the rear frame. These bolts must be

tightened to 227 Nm. These bolts must be grade

10.9.

Check the fastening of the drive motors. For

more information see page 124.

These bolts must be checked after the first 50 hours

of service, and then after every 400 hours or 1 year

of use, whichever comes first.

Check hydraulic fittings

Check hoses and fittings visible on the loader boom.

Push and pull the hoses manually and look if any

fitting is loose.

Do not overtighten hydraulic fittings. Tighten any

hydraulic fitting only if there are signs of leakage or

loose connection. Tightening of a hydraulic fitting

unnecessarily can damage it.

Make sure that replacement hoses and fittings are

compatible with the fittings on the loader. Contact

Avant service when hoses or fittings need to be

replaced.

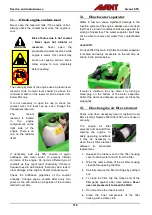

Hydraulic fittings of drive motors and hoses of

drive system

Hydraulic fittings of the drive system are equipped

with a visible marker where a yellow marker is fully

visible, when the fitting is tightened correctly. If a

hose or fitting needs to be replaced, use only hoses

which are equipped with compatible fittings.

Reuse of hydraulic hoses or fittings

Never reuse pressed fittings that are part of hydraulic

hoses. If a hose must be replaced, it must always be

equipped with new fittings. Use only high quality

hoses and fittings. Hoses must be made with

professionally made pressed fittings. Do not use

reusable hose fittings.

Summary of Contents for Avant 850

Page 1: ...English Operator s Manual 2020 A441827EN 2020 1 2020 www avanttecno com...

Page 128: ...Avant 850 128...

Page 132: ...Avant 850 132 Notes...

Page 133: ...Avant 850 133 Notes...