Service and maintenance

Avant 850

110

Tapered JIC-type hydraulic fittings may get damaged

when removed and re-tightened. Note that JIC type

fittings are not tightened with torque and fitting will

break when tightened too much.

7.

Check wheels

Check the condition of tyres and rims visually daily.

Do not use if there is visible damage on tires or rims.

If a tyre is punctured take the tyre to a professional

tyre shop. It may not be possible to repair all

punctures safely. Do not repair tyres yourself.

Check tyre pressure with a pressure gauge

whenever you suspect wrong pressure. Check the

tyre pressures at least monthly. Check tyre pressure

when heavy attachments and extra counterweights

are not attached.

Check that the tyre models are appropriate for the

loader model and listed on page 36. The load and

speed rating of the tyre and rim must be appropriate

for the loader model.

The correct tyre pressure depends on tyre model and

intended load. Refer to Chapter Technical

Specifications.

WARNING

Risk of loss of stability due to

tire failure - Never attempt to

repair a tyre by yourself.

The

loader is equipped with heavy duty

tyres that must only be repaired by

a qualified tyre technician.

.

8.

Check the attachment and the

quick coupling plate

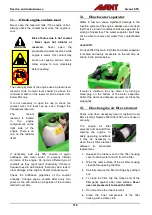

Check the locking of attachment and locking pins on

attachment coupling plate. Check both locking pins:

Both pins must move

easily and come through

the lower brackets of the

attachment.

To check the attachment

and any additional

coupling instructions for

individual attachments,

see the Operator’s

manual of the

corresponding

attachment.

The locking pins must return easily to their locking

position. Do not operate the loader if the coupling

pins do not lock down.

Clean the locking pins when cleaning the loader.

Move the locking pins regularly, even if you do not

change attachments regularly.

The quick coupling plate and its pin on top of it must

not be bent, cracked, or otherwise damaged.

Make sure that the attachment is locked, if an

attachment is mounted on the quick coupling plate.

Check the operation of the attachment, and position

of the hydraulic hoses of the attachment. Hoses must

not rub against sharp surfaces, or get stretched or

pinned when moving the loader boom and the

attachment. See also the operator's manual of the

attachment, see page 4.

Hydraulic attachment locking:

If your loader is equipped with hydraulic attachment

locking, check that both locking pins move up and

lower down completely by using the switch on the

dashboard. Do not operate the loader if the

attachment locking system pins do not lower down

completely.

Use the hydraulic locking periodically even if you

don't change attachments.

Summary of Contents for Avant 850

Page 1: ...English Operator s Manual 2020 A441827EN 2020 1 2020 www avanttecno com...

Page 128: ...Avant 850 128...

Page 132: ...Avant 850 132 Notes...

Page 133: ...Avant 850 133 Notes...