17 (28)

6.2

Operation

6.2.1

Using the log splitter

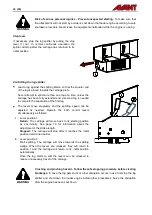

Setting up the log splitter

1.

Choose a level working site, which can

carry the load of the equipment and the

logs. Clear the area from any obstacles

that could cause a tripping hazard. The

working area must not be slippery.

2.

Operate the log splitter in daylight or

good artificial light and only in well-

ventilated areas.

3.

Set the attachment to desired height as

instructed on page

4.

Lower the log splitter firmly on the

ground and apply the parking brake of

the loader.

5.

Lower the unloading chute to the

operating position.

Make sure that the hydraulic hoses are positioned so that they will not disturb operation,

and that they will not get squeezed or chafed against moving components.

Activating and deactivating the log splitter:

1.

Make sure the log splitter is set to the working position, as described in this

manual.

2.

Adjust loader engine rpm so that hydraulic oil flow is within the recommended

range 15 - 25 l/min. Never exceed the maximum hydraulic oil flow 30 l/min.

Depending on the loader model, two hydraulic pumps may be used to reduce

engine noise. Note that unnecessarily high engine rotating speed will not

improve the splitting force.

3.

Move the auxiliary hydraulics control lever to its locking position to start

hydraulic oil flow to the log splitter.

Release the auxiliary hydraulics lever to neutral position, and follow the safe

stopping procedure whenever the log splitter is not actively used.