29

Service and maintenance instructions

Auxiliary hydraulics:

Pressure

is checked from the measuring

point, with full revs and by

turning the aux. hydraulics

control lever. Pressure setting

should be 240 bar.

Drive pressure:

In order to

check the pressure in the drive

circuit one needs to mount a

pressure gauge in the pressure

line in each and every case, if

pressure seems to be clearly wrong. There are two

pressure relief cartridges which have fixed 320 bar

(745), 370 bar (750) pressure setting.

It is recommended that pressures should only

be checked by a competent and experienced

technician. Call your AVANT dealer if you need

assistance.

10. Adjust pressure of hydr. system

If the pressure of hydraulic system does not seem to

be correct or pressure check indicates that the pressure

is wrong, it can be adjusted. All adjustment screws

are protected with a 13 mm nuts and there is a seal

ring under each nut. When taking off the nuts make

sure that the seal rings doesnt get lost. Adjust the

pressure with an allen key, max. 1/8 rounds at a time.

See pictures for pressure adjustment points.

Boom lifting

: Pressure is

adjusted from the pressure

relief valve at the main control

valve. Pressure adjustment

screw is on the right, on top of

the valve segment (see picture).

Adjust by turning the hexagonal

head screw which is under the

cap (240 bar).

Auxiliary hydraulics

: Pressure

is adjusted from the pressure

relief valve at the main control

valve. Pressure adjustment

screw is on the right, under the

valve segment (see picture).

Adjust by turning the screw

with a screwdriver (240 bar).

Drive pressure

: Can not be

adjusted. If the pressures are

clearly wrong one must change the pressure relief

cartridges which have 320/370 bar fixed pressure

setting.

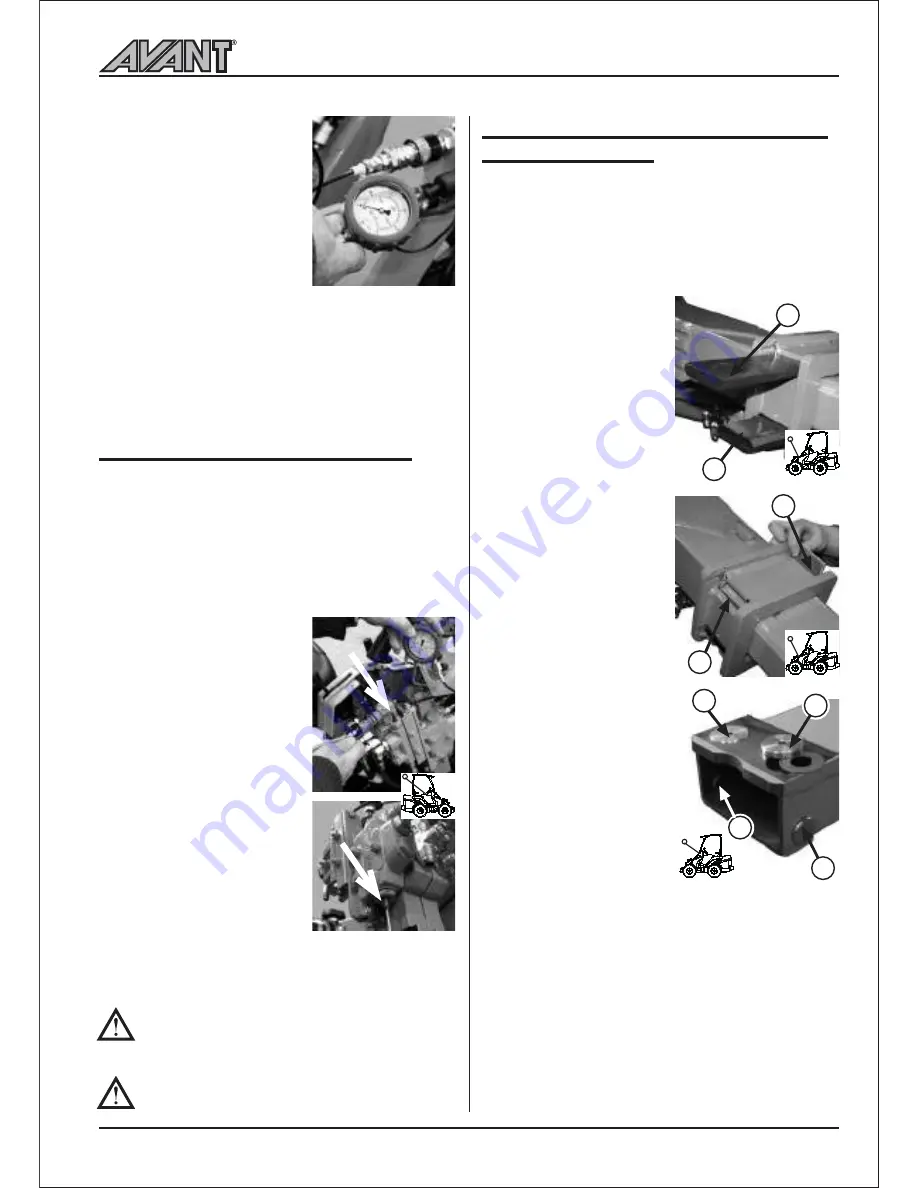

11-13 Adjust and change the slide pads

on telescopic boom

The telescopic boom is equipped with slide pads. At

the lower end of the outer boom there are slide pads

made of nylon (nos. 1 and 2) and bronze (nos. 3 and

4). In addition, there are four slide pads (nos. 5, 6, 7

and 8), made of aluminium-bronze alloy, at the upper

end of the inner boom. All slide pads can be replaced,

and the nylon slide pads on

the outer boom can also be

adjusted. This way the

natural wear of the slide

pads, caused by the use of

the telescopic boom, can be

compensated.

Slide pads nos. 1 and 2

can be adjusted by mounting

thin adjustment sheets

between the boom and the

slide pad. Extend the

telescope almost completely

and press the boom against

the ground, it is the easiest

way to mount the

adjustment sheet under slide

pad no. 2. However, if there

is substantial wear in the

slide pads it is advisable to

replace both pad no. 1 and

2.

Slide pads nos. 3 and 4

on

the side of the outer boom

and

slide pads nos. 5, 6, 7

and 8

at the upper end of

the inner boom last very

long in normal use.

Slide pads 3, 4, 5, 6, 7 and

8 should be checked every

400 operating hours.

Checking happens by taking

the inner boom completely

out of the outer boom. If

the pads have worn so much that they are level with

the boom, change the pads.

Part nos. for the slide pads are:

Slide pad 1 and 2: A48339

Slide pad 3 and 4: A48340

Slide pad 5 and 6: A47922

Slide pad 7 and 8: A48343

Washer under slide pads 5 and 6: A47941

Adjustment sheet, short: A48013

Adjustment sheet, long: A48014

6

8

5

7

2

1

3

4

Never exceed the recommended hydraulic

pressure settings. Excessive hydraulic pressure

will damage the hydraulic pumps, cylinders,

and hydraulic motors.

Warranty does not cover damages caused by

excessive hydraulic pressure.

700 Series

https://tractormanualz.com