5(18)

4.

Safety instructions for installing hydraulic components

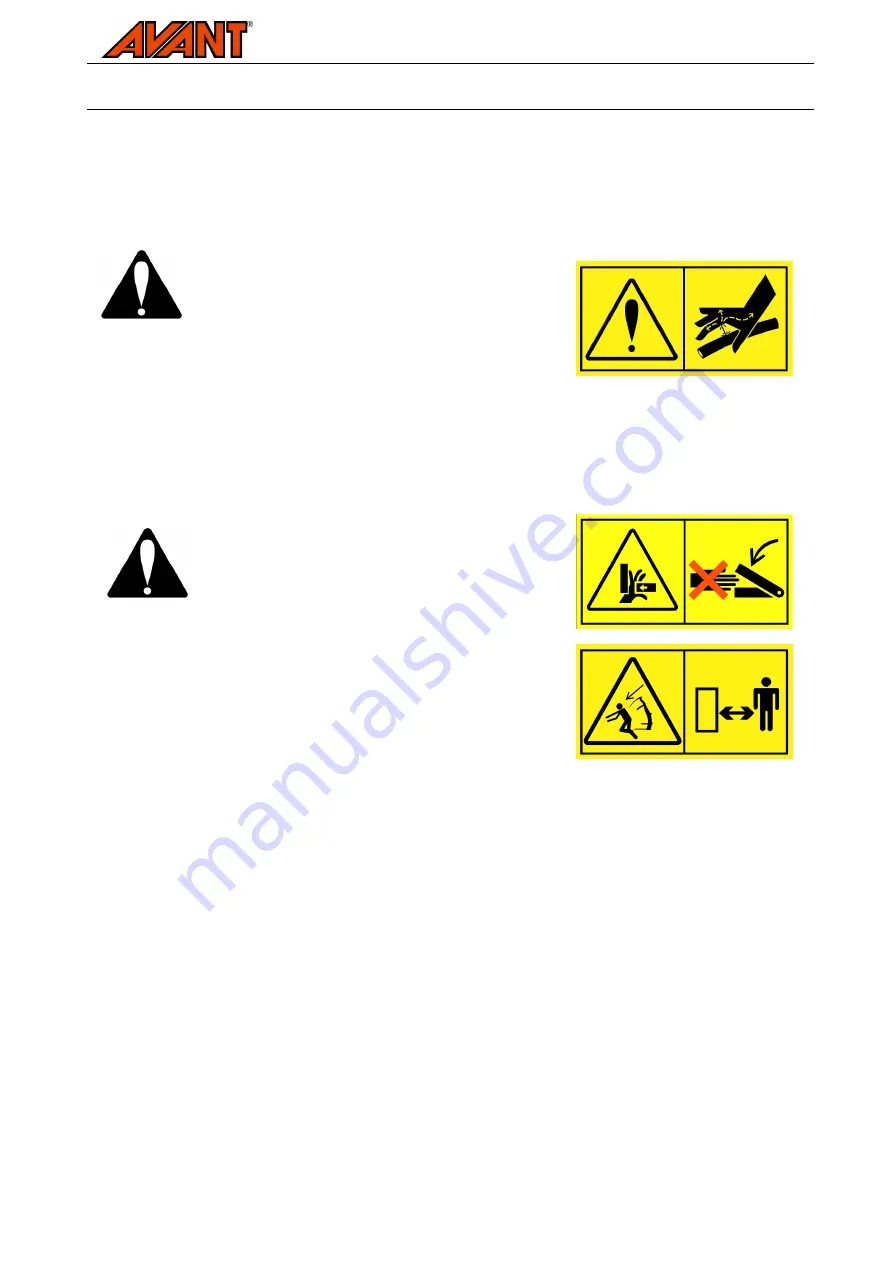

The following safety procedures must be followed when handling hydraulic components. Contact your

nearest Avant dealer or service point if you have any additional questions or if you need installation services.

It is recommended to leave the installation of hydraulic components to professional service technicians.

Before handling hydraulic components, make sure

that the hydraulic system of the attachment and the

loader are completely depressurized. Never handle

pressurized fittings. See instructions on page 14 to

release the residual pressure. Do not hold your

hand near a fitting when tightening or opening it.

High pressure fluid ejection may penetrate skin and

cause serious injuries. Seek medical attention

immediately in case hydraulic fluid is injected into

the skin.

Make sure the attachment is securely lowered on

the ground. Any part of the attachment must not be

supported only by the hydraulic pressure or

hydraulic cylinders. Do not loosen any fitting as long

as any part of the attachment may move. Use

additional supports as necessary. Lower the

attachment securely on the ground, shut down the

loader engine and lower the grapple on ground or

additional supports. Depressurize the hydraulic

systems completely.

Ensure that the loader boom or any part of the attachment will not move and cause a crushing hazard:

1. Lower the boom to its lowest position

2. Lower the attachment firmly on the ground

3. Lower the grapple or otherwise block the movements of the grapple. Use additional supports or

lifting equipment as needed.

4. Shut down the loader engine.

5. Move the auxiliary hydraulics control lever to its extreme positions several times to release residual

pressure.

Summary of Contents for A2868

Page 18: ......