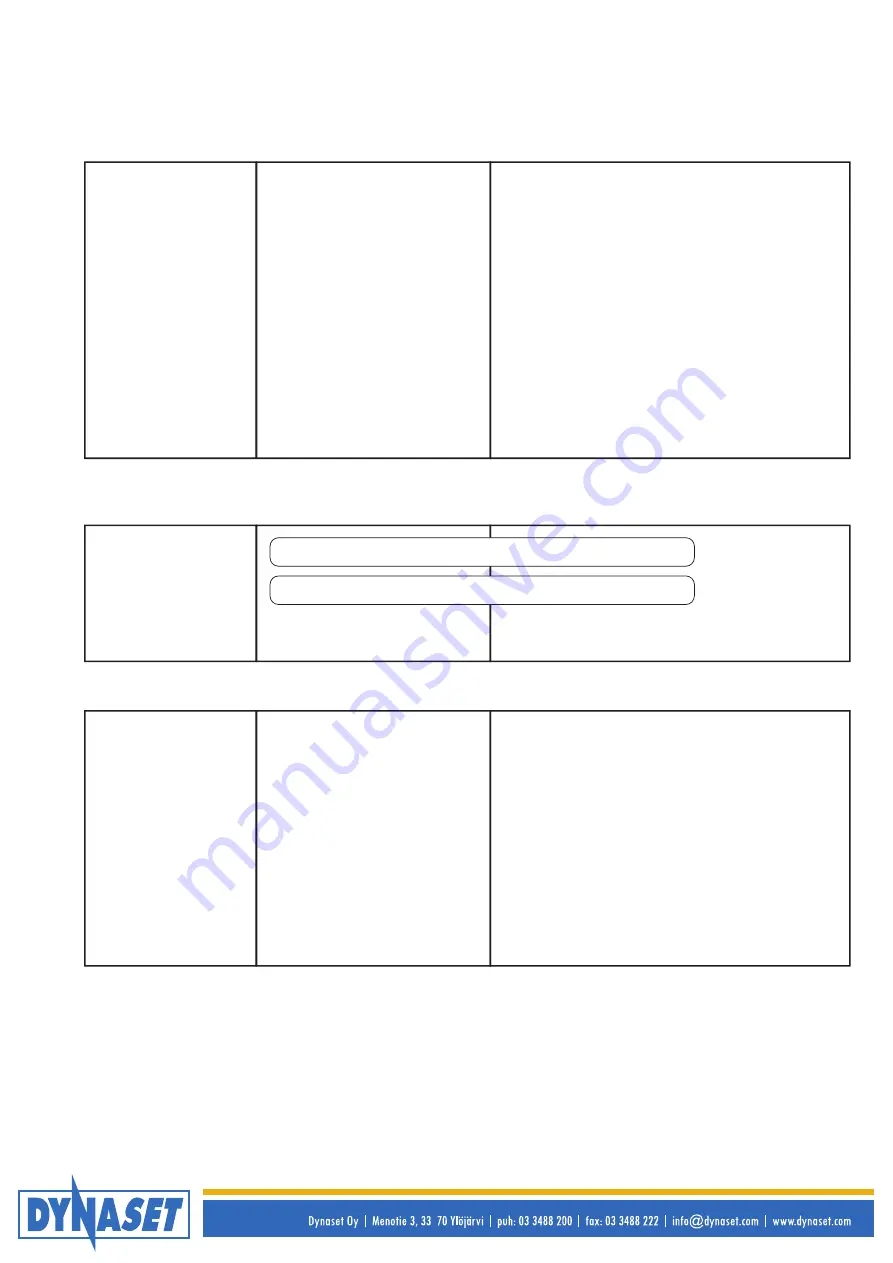

1.1

Malfunction of compressor’s hydraulic

control valve.

1.2

Compressor’s excessive internal pressure.

1.3

Failure in hydraulic system.

1.4

Air pressure in delivery line interferes

compressor’s start.

1.1

Check and repair.

1.2

Release the frame tank’s pressure, for instance, by means of

3-way valve installed to the delivery line).

In case of intermittent / cyclic duty, either electric pressure

switch (-E) or pneumatic cut-off (-PNE) is recommended.

1.3.1

Check whether the hydraulic fluid flow and pressure are

sufficient. Adjust when necessary.

1.3.2

Check the hydraulic motor for possible leakage. Replace

motor if necessary.

1.4

Let off the pressure from the delivery line prior to staring the

compressor.

Ref. to 1.2

1.

COMPRESSOR DOES

NOT START WHILE

CARRIER’S ENGINE IS

RUNNING AND

HYDRAULIC SYSTEM IS

ON.

2.

COMPRESSOR STARTS

HARDLY

See 1.3

See 1.4

3.

AIR PRESSURE DOES

NOT ACHIEVE

REQUESTED RATE.

3.1

Safety valve’s failure or incorrect

setting.

3.2

Failure in hydraulic system.

3.3

Intake air filter is clogged.

3.1

Check and adjust / replace when necessary.

3.2.1

Check whether the hydraulic fluid flow and pressure are

sufficient. Adjust when necessary.

3.2.2

Check the hydraulic motor for possible leakage. Replace

motor if necessary.

3.3

Check and replace.

TROUBLESHOOTING

17/21

MAY CHANGE WITHOUT PRIOR NOTICE

HYDRAULIC COMPRESSOR HK400/8-23_PNE

July 2013 JLe