5(24)

2.

Designed purpose of use

The hydraulically operated air compressor is intended for use with Avant 300-700 series multi purpose

loaders as an easy to use and transportable attachment. Compatible loader models are shown in Table 1

below. The strong and robust compressor makes use of the auxiliary hydraulics oil flow of the loader, making

it possible to have high output of compressed air easily near work site even in difficult conditions. The

compressor can be used with all typical pneumatic equipment requiring compressed air, such as different

hand tools, painting work, construction work, or filling tyres, if the tool or device is compatible with the 8 bar

pressure produced by the compressor. If needed, the compressor can be connected to a larger system to

provide temporarily compressed as a back-up compressor.

The operating speed of the compressor depends on the loader engine rpm and hydraulic oil output, and in

addition, the compressor is equipped with a hydraulic operating speed compensator to reduce the maximum

operating speed of the compressor. The compressed air reservoir is integrated to the frame of the

compressor and it is equipped with a standard type quick fitting to connect equipment. A pneumatic valve will

stop the compressor and set the hydraulic flow to free circulation when the pressure in the reservoir reaches

operating pressure. Connecting the compressor block directly to other systems by bypassing the integrated

reservoir is prohibited. Depending on the compressor model, it can be attached to the front quick coupling of

the loader, or it can fitted to the back of the loader with mounting bracket, leaving the boom available for

another attachment. When using the compressor, it must be attached and locked to the loader. The

compressor is intended to produce compressed air, other gas types are not allowed.

The attachments have been designed to require as little maintenance as possible. The operator can perform

regular maintenance tasks. However, all repair work can’t be performed by the operator, and demanding

repair and maintenance operations must be left for professional service technicians. All maintenance work

must be done using proper safety equipment. Spare parts must be identical with original specifications,

which can be ensured by using only original spare parts.

Familiarise yourself with the manual's instructions regarding service and maintenance. Please contact your

AVANT or Dynaset retailer if you have additional questions about the operation or maintenance of the

equipment, or if you require spare parts or maintenance services.

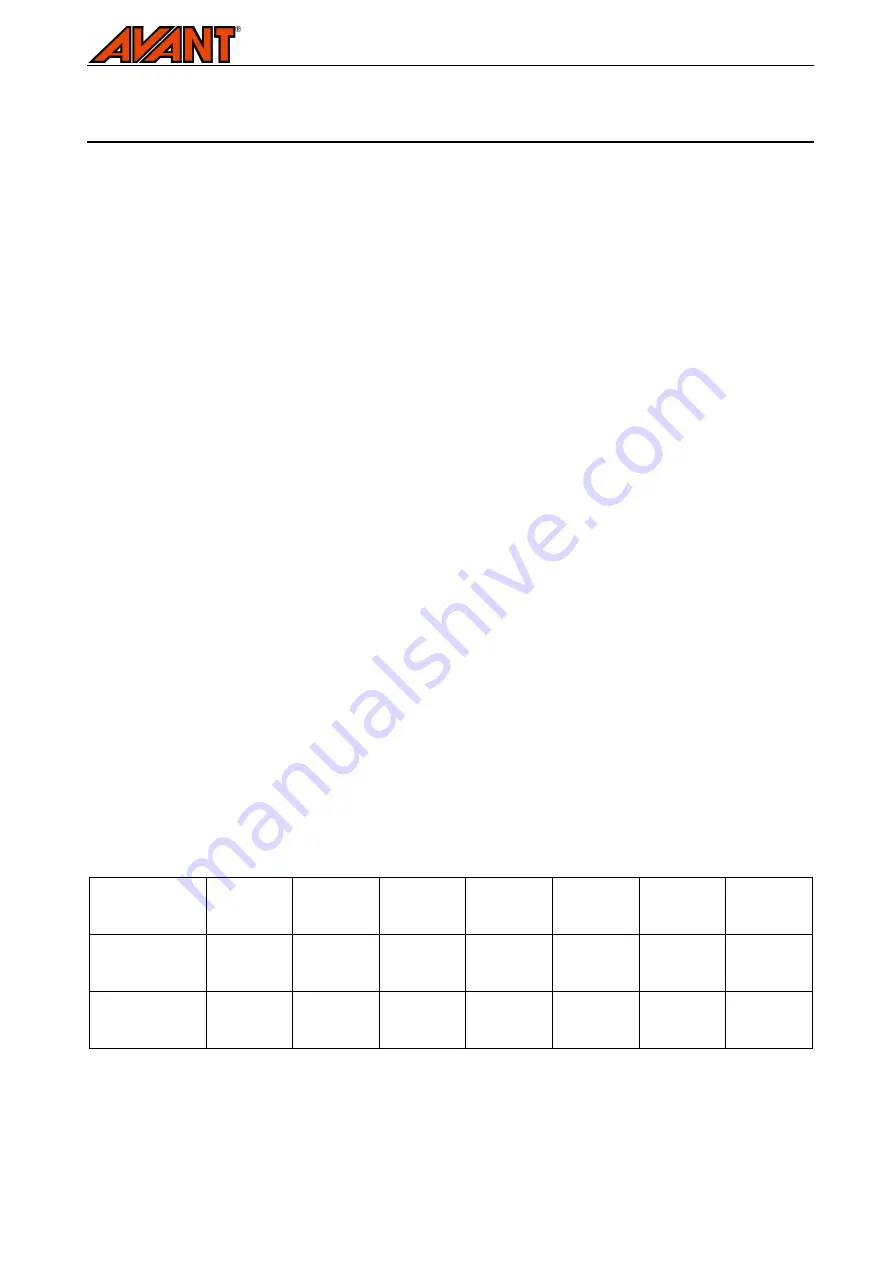

Model

216

218

220

313S

320S

320S+

419

420

520

528

525LPG

R28

R35

630

635

640

745

750

Front mount

A35409

-

••••

••••

••••

••••

••••

••••

Rear mount with

bracket

A35456

-

-

••••

••••

-

••••

••••

When fitting the compressor to the back of the loader, the loader must be equipped with double acting rear

auxiliary hydraulics. In this case, the rear side weights can’t be used.

Table 1 – Compatibility of compressor models A35409 and A35456 with Avant loaders